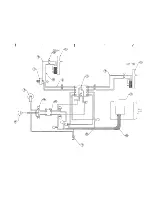

ACCU-TURN 7700 COMBINATION BRAKE LATHE

OPERATION PROCEDURES

MOUNTING AND MACHINING PROCEDURES

Inspection of Brake Drums and Disc Rotors Before Machining

IMPORTANT: The maximum amount of metal removed from the finished workpiece

should never exceed the manufacturer's specifications. It is dangerous to operate a vehicle

with a drum or rotor which has had more material removed than is allowed. Proper

operation cannot be established if these specifications have been exceeded. Accu

Industries recommends that each workpiece be checked for size before mounting on the

lathe and after machining.

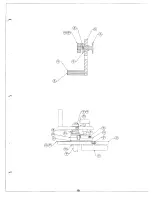

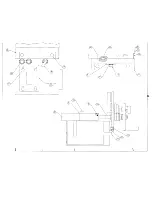

Mounting Hubless Drums or Rotors

1.

Clean and check for flatness all surfaces that will come in contact with centering

cones and/or bell clamps to ensure solid mounting.

2.

Cleaning and properly mounting the drum or rotor prior to machining will ensure a

minimum of stock removal, better surface finish, and optimum braking efficiency.

3.

Excessive run out or wobble of the drum or rotor after it has been properly cleaned

and mounted on the arbor may indicate severe damage to the drum or rotor. These

drums or rotors should not be used for further service.

a.

Select proper size bell clamps and slide one on the arbor. The bell clamp

selected should reference the same area on the vehicle from which the rotor

or drum takes its alignment.

On hubless drums, the largest doubled tapered radius cone available will be

installed on the arbor before first bell clamp for almost 100 % of set-ups to

provide drum clearance from drum slide. Rotor should be positioned to

give clearance for installing drum or rotor on arbor.

b.

Slide spring on the arbor.

c.

Choose the centering cone adapter that fits the center hole of the drum or

rotor and slide it on the arbor.

d.

Slide the drum or rotor on the arbor and then the other bell clamp.

e.

Add necessary spacers (double-tapered radius adapters may be used as

spacers), hex nut and tighten securely. Use spanner wrench to hold spindle

while tightening arbor nut. Do not jerk or hit with wrench.

7