During machining, material removal may cause a sharp edge

to be generated, where a chamfer or radius previously existed.

Use care in handling machined parts.

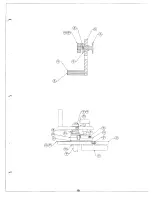

3.

Securing the Machine:

The model 77 00 weighs approximately 300

pounds and must be bolted to an ACCU-TURN Heavy duty Floor

Stand or a bench capable of supporting the machine, its

accessories and workpiece.

4.

Grounding the Mach i n e :

Machines eguipped with a three-prong

grounding plug are so eguipped for your protection against

shock hazards and should be plugged directly into a properly

grounded three-prong receptacle in accordance with national

codes, local codes and ordinances.

A grounding adapter

may be used only if the green lead is securely connected

to a suitable electrical ground. Do not cut off the grounding

prong or use an adapter with the grounding prong removed.

5.

Eve Safety:

Wear an approved safety face shield, goggles,

or safety glasses.

6.

Personal Protection:

Before operating the machine, remove

tie, rings, watches, and other jewelry, and roll up sleeves

above the elbow.

Remove all outer loose clothing and confine

long hair.

Protective type footwear must be worn.

Hearing

protectors must be used where noise exceeds the level of

exposure allowed in Section 1910.95 of the OSHA Regulations.

DO NOT HEAR GLOVES

7.

DO NOT OPERATE MACHINE WITHOUT ITS GUARD

(S').

8. Work A r e a :

Keep the floor around the machine clean and

free of foreign materials.

ACCU Industries recommends the

use of anti-skid floor strips where the operator normally

stands, and that each machine has its own work area marked

off.

Make certain that the work area is well-lighted and

ventilated.

Provide for adeguate work space around the

machine.

The work area should not be readily accessible to

anyone except the operator.

4