18

Actions required to prevent frost

(Water Removal in Water Tank and Evaporator)

• If the ambient temperature falls below 0°C/32

o

F, water will freeze inside the machine and machine

operation will be impossible.

• If not use in for a long period of time in the winter, be sure to completely remove the water inside the

body by following the instructions below. If you do not remove the water or if it is insufficient, it will cause

serious damage to the product. This shall not be guaranteed by the manufacturer and may result in

repair costs. Please observe the following points.

1.

Turn on the power switch and press the DOWN + SET

button at the same time for 3 seconds with any signal

on the FND window. Forced drainage will be done for

30 seconds.

2.

Turn off the power switch and disconnect the power

plug from the outlet.

3.

Remove the uppe

r panel → the front panel.

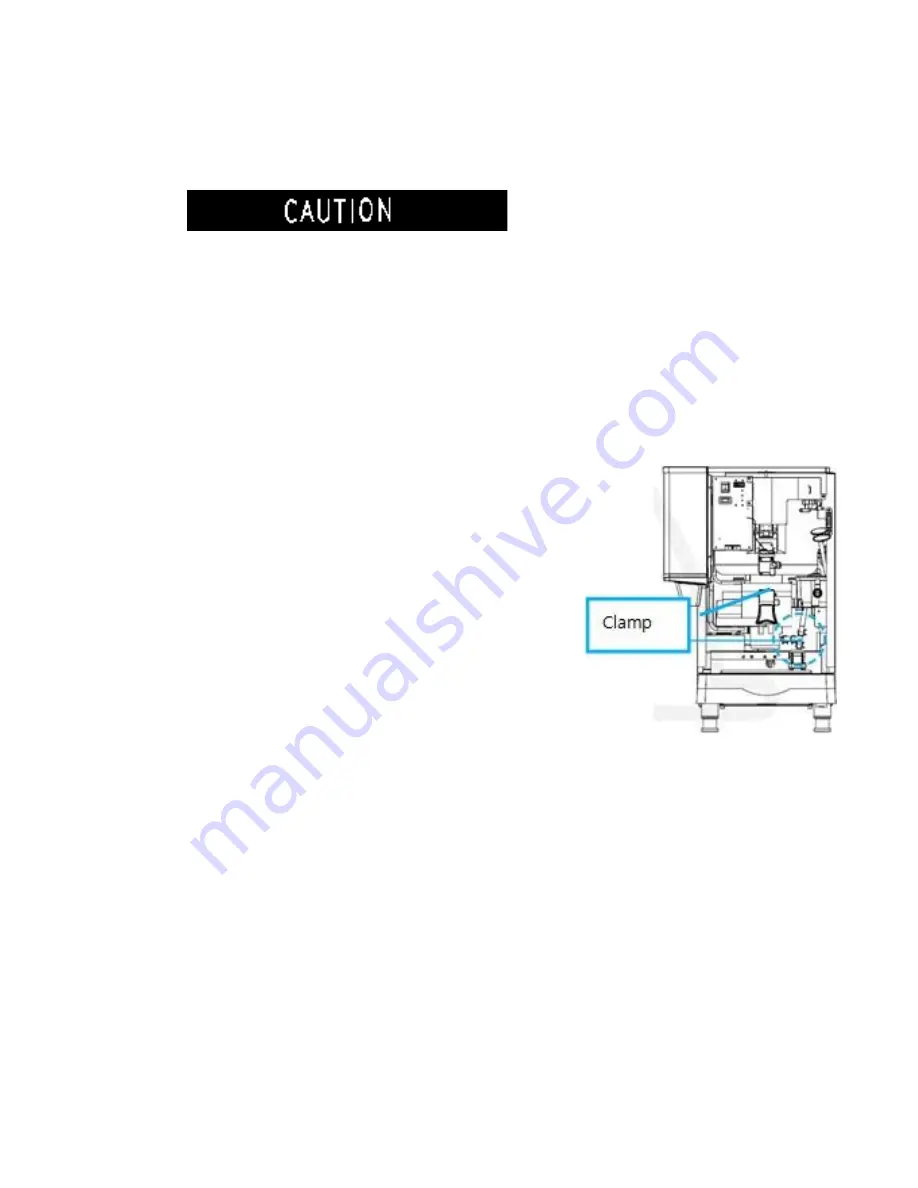

4.

Remove the evaporator cylinder drain hose clamp

and

remove the hose, and wait until the ice in the

evaporator cylinder completely melts down. It is

possible to remove internal water quickly by using

compressed air gun etc.

5.

Reassemble the evaporator cylinder drain hose

and tighten the clamp.

6.

Assemble in the order of left pane

l → upper

panel → front panel.

• AIWD450: back panel

→ upper panel

Emptying the drainage gutter (AIWD450)

•

When the water in the front drain is full, a white float comes up, so empty out the drain and

pour water.

•

(If water overflows, it may flow onto the floor, so empty it from time to time).

Summary of Contents for AIWD160

Page 7: ...7 Location of Parts AIWD282 SCIWD282 Front Top Bottom...

Page 8: ...8 Location of Parts AIWD450 Front Rear Top Bottom...

Page 9: ...9 Location of Parts AIWD160 Front Rear Top Bottom...

Page 24: ...24 Circuit Diagrams AIWD282 SCIWD282 AIWD450...

Page 25: ...25 Circuit Diagrams AIWD160...

Page 28: ...28 NOTES...