C-25 Live Steam

Technical Specifi cations

Live Steam

Scale/Gauge: 1:20.3, 45 mm Gauge

Length:

33.25 in. (845 mm)

Width:

6.44 in. (164 mm)

Height:

7.52 in. (191 mm)

Minimum Radius: 48 ins. 1.2 M

*

Be sure to leave at least 3” clearance

(measured from the inner rail) to allow

for overhang.

Caution!

This model is an accurate replica of

the original locomotive. It has sharp

and moving parts. The locomotive

drive rods are stainless steel with

sharp edges. AT ANY TIME, OPERA-

TORS MUST NOT COME IN CON-

TACT WITH THE MODEL WHILE

IT IS POWERED. UNDER NO CIR-

CUMSTANCES SHALL ACCUCRAFT

TRAINS BE RESPONSIBLE FOR ANY

INCIDENTAL OR CONSEQUENTIAL

DAMAGES ARISING IN REGARD TO

ANY ACCUCRAFT PRODUCT.

Accucraft Trains locomotives are fi ne

scale brass models with small parts.

To provide maximum protection from

shipping damage, we carefully pack

the models in metal cases. We ship

via UPS with insurance coverage to its

full value. Please contact UPS if pack-

age is damaged.

Each locomotive is packed under

UPS guideline for shipping. We don

not warrant any damage resulted from

re-packaging by any party other than

Accucraft Trains.

Please read following directions be-

fore unpacking your locomotive.

1. Lift the box from the cardboard

box.

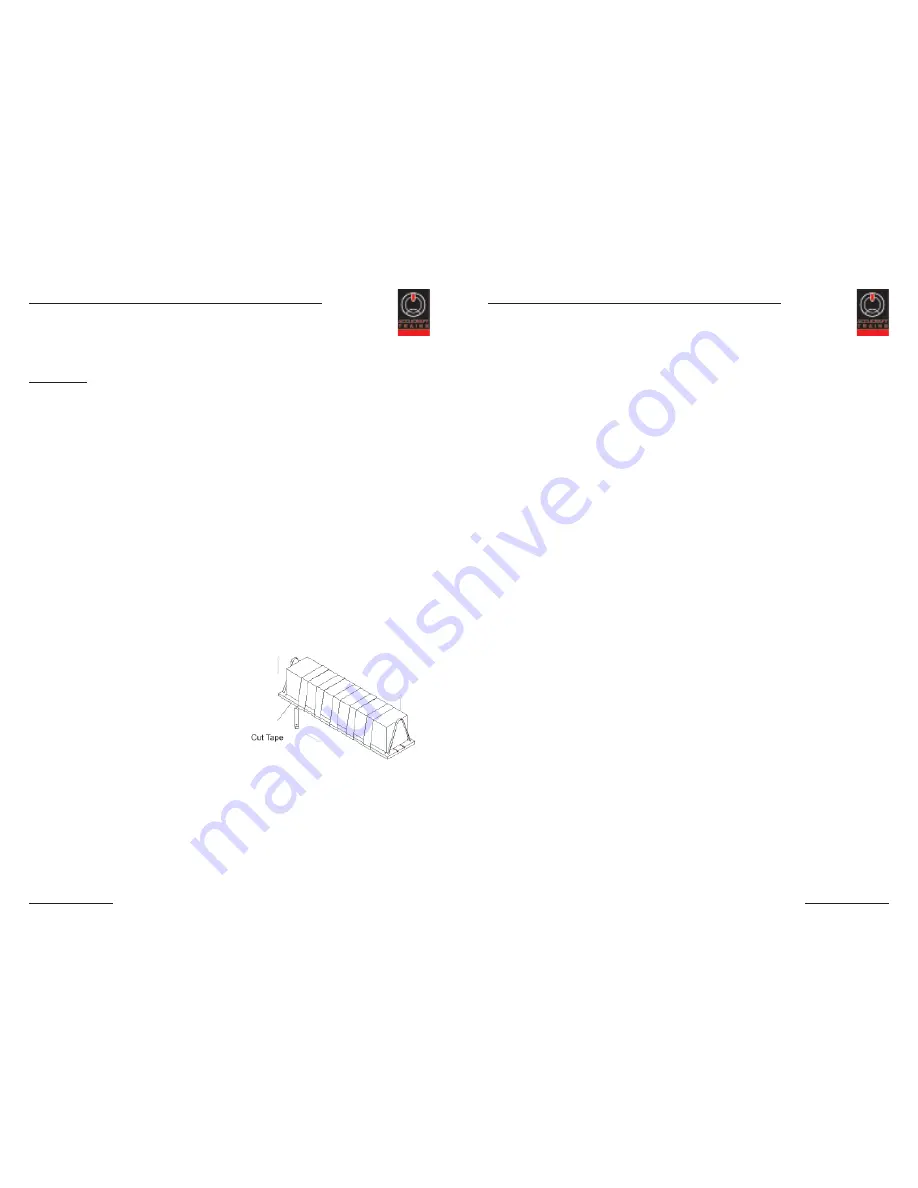

2. Place taped locomotive on a fl at

surface. Carefully cut the tape along

the wood board side surface. Be sure

to cut both sides of the wood board.

Slowly lift the tape from the locomo-

tive. Be very careful with small parts.

Tape cannot be re-used to re-pack the

model. Use new packing tape if nec-

essary.

9

C-25 Electric

2

Lubrication

Lubricants: always use quality

lubricants!

Light oil such as Labelle #108 or Wahl

Clipper Oil. Heavy lubricant such as

Labelle #102 heavy gear oil or Labelle

grease.

Prepare the engine for lubrication by

placing the model gently on the work

surface. To protect the locomotive

finish, place the engine on a piece of

foam sheet or soft towel. The engine

should be placed on its side. Be

careful to keep the lubricant off of the

painted surfaces, as this can leave

a shiny appearance on the area it

touches.

Oil all external moving parts of the

engine, including wheel bearings, with

a high grade, lightweight machine oil

like 3-in-1. Be sure to oil all parts of

the drive train. A little oil is all that’s

necessary.

It is a good idea to wipe off all excess

light oil when you complete the

lubrication process.

THIS LUBRICATION SHOULD BE

REPEATED AFTER EVERY 25 HOURS

OF OPERATION!

After following the recommended

lubrication procedures, your

locomotive is ready to provide many

years of enjoyment and reliable

operation. We recommend that you

use a D.C. power supply with a

capacity of 2.5 amps or larger and 24

volts.

Always pick your model up by grasping

it under the frame on both ends. It is

a very heavy model so make sure that

you grasp it firmly.

General maintenance

Clean the exterior surfaces of your

locomotive with a clean, soft and lint

free cloth.

The following parts are packaged sep-

arately

- M2 hex head screws

- 3 mm hex head screw driver

- Whistle pull cord