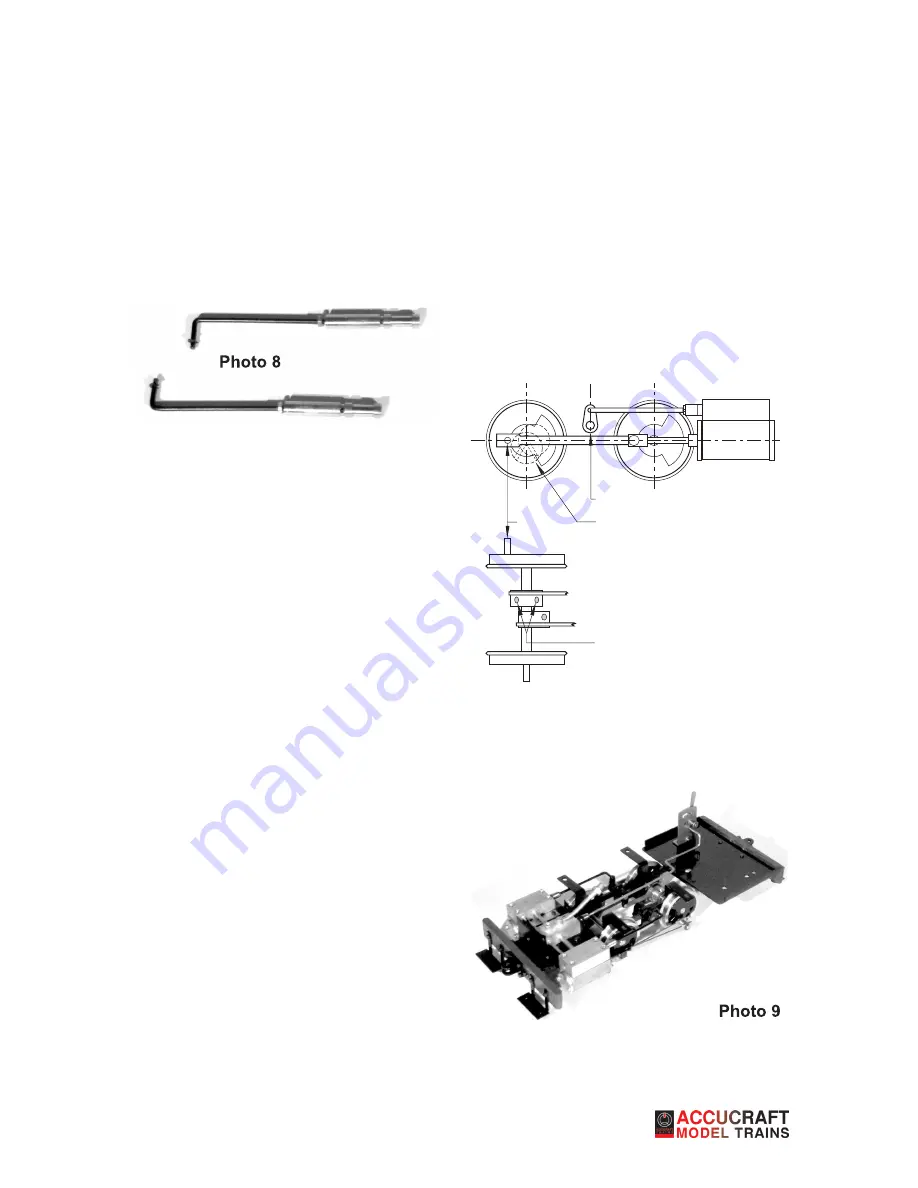

3-8.

On the short leg of each valve rod (41) are two

small grooves. Snap an e-clip (42) onto each inner

groove. Carefully remove each valve from the valve

blocks and screw them onto the ends of the valve

rods (photo 8). Do not tighten the nut against the

valve at this point, as the valves will have to be ad-

justed later.

Put a little oil on each valve and carefully return it to

its place in the valve block. Insert the other end of

each valve rod through its respective hole in each

rocker arm and secure it with an e-clip (42) in the

outer groove.

3-9.

The eccentrics are the brass discs on the rear

axle. Each has two threaded holes in it with set

screws installed. Loosen the set screws but do not

remove. Slightly tighten one set screw in each ec-

centric, just enough so that when the wheel is rotat-

ed, the eccentric revolves with the axle.

Adjusting the Valve Travel

As with the reversing valve, each of the cylinder

valves has a tiny groove machined into it. In the

valve’s forward-most position, that groove should

be just touching the valve back.

Taking one side at a time, rotate the drivers and

observe the valve’s travels. If the tiny groove trav-

els inside the valve block, screw the valve farther

onto the valve rod. This can be done with the valve

in place – no need to disassemble anything. If the

groove never reaches the block, screw the valve in

the other direction. When the groove finally touches

the block in the valve’s forward-most position, se-

cure the valve on the rod by carefully tightening the

nut against it, making sure that the valve doesn’t

rotate while you are doing so.

Setting the valves

Loosen all of the screws in the eccentrics so that

the eccentrics rotate freely on the axle. Working

with the chassis upside down, rotate the wheels so

that the right-hand side is at rear dead center (i.e.

the piston rod is out as far as it will go – see figure

1). Without rotating the axle, rotate the right-hand

eccentric so that the two holes are equidistant on

either side of the axle when looking straight down

on it. Tighten one screw.

Now follow the same procedure for the other side.

If your work was done correctly, the valves should

now be set and you should have a working chassis.

The finished chassis can be seen in photo 9.

Right side view

Underside view

Figure 1—Setting the valves

Crankpin at

rear dead center

Right eccentric

facing down

Rocker arm straight

up and down

Eccentric holes equally spaced

on either side of axle

4

Summary of Contents for Ruby 0-4-0T Kit

Page 1: ...Ruby 0 4 0T Kit Assembly Instructions...

Page 9: ...7...

Page 10: ...8...

Page 11: ...9...