3-14.

Place the boiler on the chassis. Screw an

M3-5 phillips-head screw (31) through the deck and

into the rear mounting stud from underneath. Do

not tighten it too much yet.

Fasten the smokebox to the saddle with two M2

x 4 phillips-head screws (40) through the saddle

plate, as per the drawing. This is most easily ac-

complished by inserting your screwdriver through

the smokestack hole for access to the screws. The

screws can be put in position with needle-nose pli-

ers through the smokebox door.

Referring to the drawing, carefully bend the short

leg of the steam pipe until it will smoothly mate with

the thread on the throttle. The two must be well

aligned for a steam-tight fit. Secure the union nut

to the throttle.

3-15.

Place the smokestack washer (53) on the

smokestack nut (52) with the flat side bearing

against the nut. Open the smokebox door, insert the

nut and washer from inside, making sure the cur-

vature of the washer conforms to the curve of the

smokebox, and screw the smokestack (54) partway

on. Tighten the nut, making sure the curvature of

the bottom of the stack conforms to the smokebox.

Secure the nut tightly with pliers.

Drop the exhaust pipe (55) down the stack and

screw it into the valve-block. It need only be finger

tight.

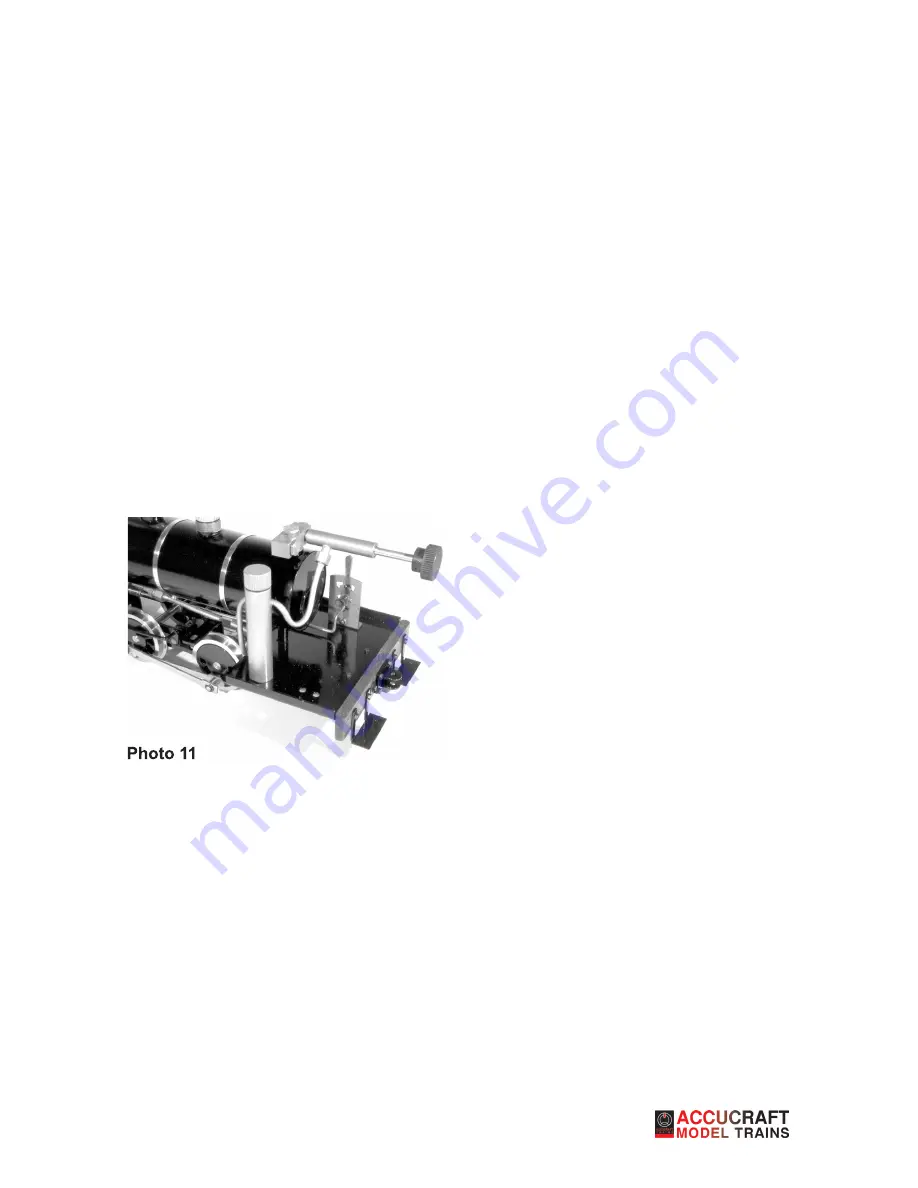

3-16.

Slip the burner (25) into the flue opening in

the back of the boiler and secure it with an M2 x 4

screw (3). Secure the gas tank (28) to the deck with

one cap nut (29). Slide the jet (26) into the back of

the burner. Carefully and gently bend the copper

gas line until the threaded part of the gas valve lines

up well with the end of the gas line (photo 11). Tight-

en the union nut to the gas valve.

At this point you should have a working locomotive.

Ruby was designed so that the cosmetic compo-

nents (cab and tanks) could be easily modified. The

boiler and chassis comprise the working portion of

the engine. If you’d like, you can try it under steam

now, or you can wait until the tanks, cab and domes

have been applied.

Refer to Sheet 5

5-1.

Take the steam dome base (66) and place it

over the safety valve. The steam dome (65) screws

to the safety-valve bushing, securing the base. The

sand dome (64) merely slips over the filler plug and

is held in place by gravity. Be sure to the remove it

before turning the engine upside down.

5-2.

Lay the side tank support bars (61) across the

brackets, beneath the boiler. Take the right-hand

tank (62) and place it on the bars. Holding every-

thing in place, carefully turn the engine over and

fasten the tank with two M3 x 5 screws (31). Repeat

with the left tank (67).

5-3.

Screw the cab sides (69, 71) to the cab front

as per the drawing, with M2 x 3 screws (72). Then

attach the roof with four M1.6 x 4 screws (73). Rec-

ommend attaching the front two screws first and

then the rear two screws. The cab should slide eas-

ily over the boiler. If it does not, file the inner edges

of the cutout around the boiler until it does.

That completes the Ruby kit. Now go outside and

enjoy many years of steaming.

6

Summary of Contents for Ruby 0-4-0T Kit

Page 1: ...Ruby 0 4 0T Kit Assembly Instructions...

Page 9: ...7...

Page 10: ...8...

Page 11: ...9...