Fire Ready Hood

7

Installation

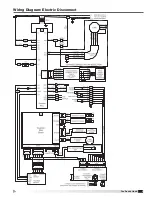

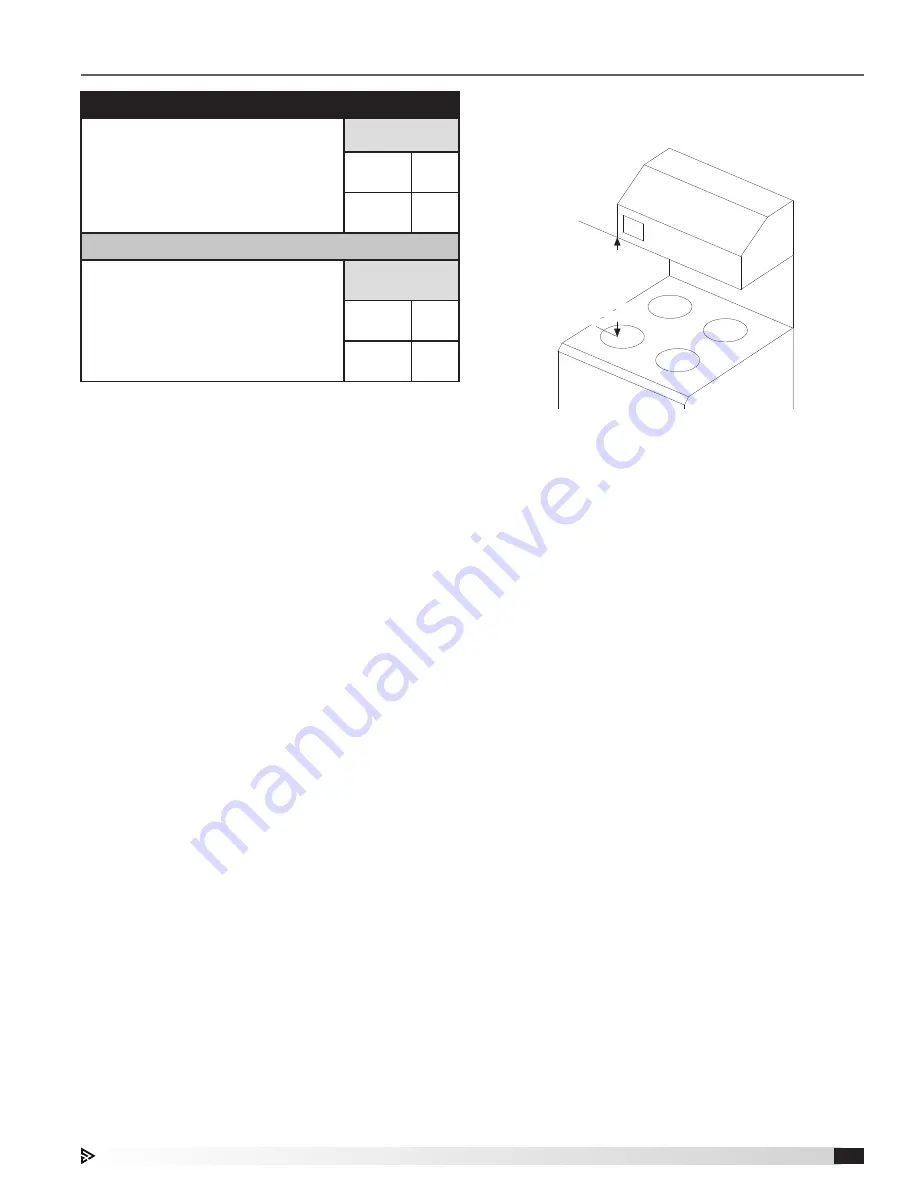

It is recommended that before drywall is hung, all

electrical cables that need to be run within the wall

should be run through the wall to their corresponding

components. Mount the control j-box to line up with

the right corner of the hood mounting bracket and run

cables for these components into this box through the

grommets. Confirm all critical mounting points will need

to be secured through studs or utilize dry wall hangers.

Hood weight should be supported by at least two (2)

studs. Hood needs to be centered above the range and

within the height requirements shown. Make sure that

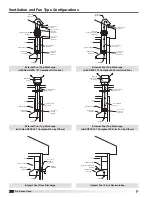

with integral fan – rear discharge configurations, the

studs and control j-box do not interfere with the rear

discharge duct.

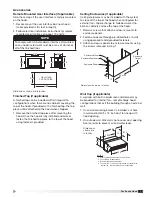

After drywall is hung, affix mounting bracket to wall

using the necessary field provided fasteners through the

critical mounting points.

Minimum Spacing:

24 inches

Maximum Spacing:

30 inches

Measure vertical distance

from bottom of hood to

cooking surface

Measure vertical distance

from bottom of hood to

cooking surface

Hood to Cooking Surface

Spacing Recommendation

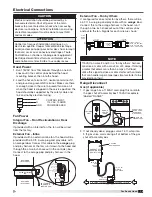

WARNING

Failure to affix the mounting bracket

to studs correctly can lead to

structural damage and/or serious

injury. The structural integrity of

the wall is the responsibility of the

contractor.

Hood Weight

30 inches 86 lbs.

36 inches 93 lbs.

AVERTISSEMENT

Si le support de fixation est mal posé

sur les montants, il peut y avoir des

dommages structuraux et/ou de

graves blessures. L’entrepreneur est

responsable de l’intégrité structurale

du mur.

Poids de la hotte

76 cm

(30 po)

39 kg

(86 lb)

91,4 cm

(36 po)

42,2 kg

(93 lb)