Upblast Centrifugal Roof Exhaust

11

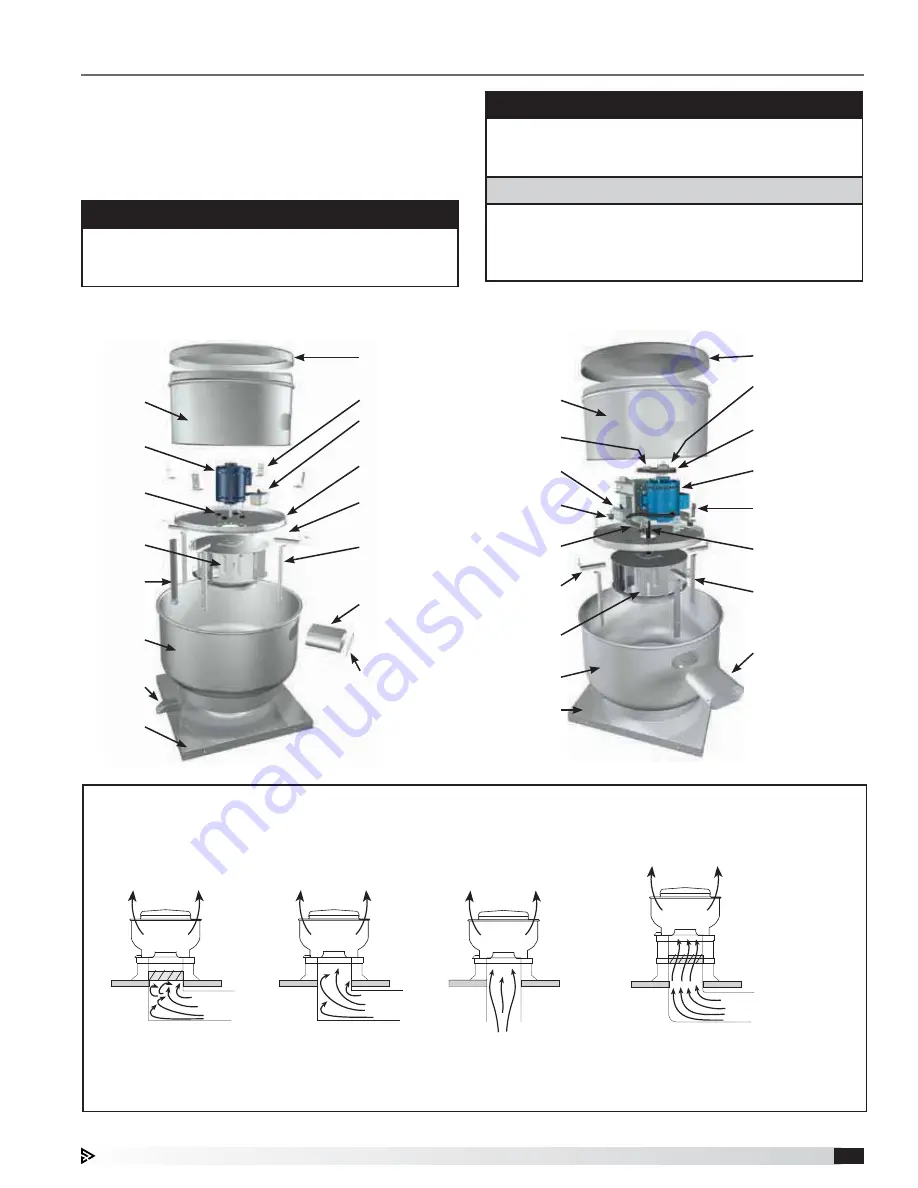

Fan Inlet Connections

In order to ensure proper fan performance, caution must be exercised in fan placement and connection to the ventilation

system. Obstructions, transitions, poorly designed elbows, improperly selected dampers, etc, can cause reduced

performance, excessive noise and increased mechanical stress. For performance to

be as published, the system must provide uniform and stable airflow into the fan.

Poor

Poor

Good

Good

Dampers must open fully. Use

motorized dampers in low airflow

applications to reduce losses.

Avoid sharp turns or entrance

conditions which cause uneven

flow. Use turning vanes in elbows

to reduce adverse effects.

Provide uniform airflow at fan inlet

to ensure optimum performance.

Provide uniform airflow at fan inlet and

through the damper to ensure optimum

performance. Curb cap should be three

wheel diameters from the radius. Use

turning vanes in duct when possible.

Motor Cover

Belt

Motor

Pulley

Motor

Fan Shaft

Curb Cap/

Venturi

Shaft Pulley

Drive Frame

Assembly

Vibration

Isolators

Vertical

Support

Windband

Wheel

Breather Tube

Birdguard in tube

Hoodband

Disconnect

Switch

Hoodband

Bracket

Horizontal

Support

Belt Drive

Direct Drive

Curb Cap/

Venturi

Wheel

Vibration

Isolators

Motor

Hoodband

Conduit

Chase

Horizontal

Support

Vertical

Support

Hood Clip

Motor Cover

Birdguard

Breather Tube

Motor

Support Pan

Disconnect

Drain

Trough

Windband

Parts List

CAUTION

A fan manufactured with an explosion resistant motor

does not certify the entire unit to be explosion proof.

Refer to UL Listing mark for the fans approved usage.

CAUTION

La présence d’un moteur antidéflagrant sur un

ventilateur ne garantit pas que tout l’appareil est

antidéflagrant. Pour connaître les emplois autorisés

de l’appareil, voir son marquage de conformité UL.

NOTE

For replacement, the windband, vertical supports,

drain trough and curb cap/venturi come as one

complete assembly.

Each fan bears a manufacturer’s nameplate with model

number and serial number embossed. This information

will assist the local representative and the factory in

providing service and replacement parts. Before taking

any corrective action, make certain unit is not capable

of operation during repairs.