Upblast Centrifugal Roof Exhaust

4

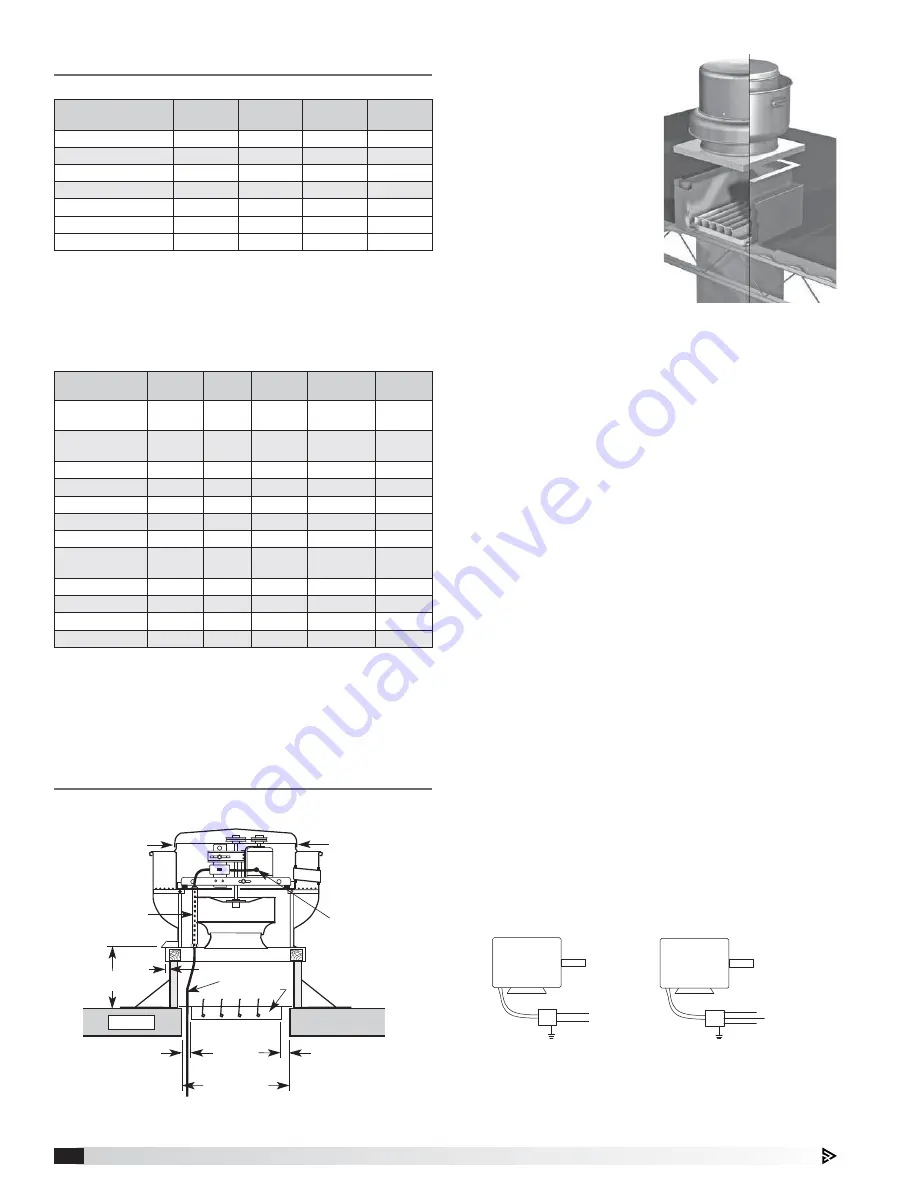

Figure 4 - Typical Roof Mounting Installation

Installation

General Ventilation Installation

8 or 12 in. min.

(203 or 305 mm)

Recommended

Roof Opening

Recommended

Duct and

Damper Size

Wiring by

Others

Factory Wired

Motor to

Disconnect

Roof Deck

Damper

Screw

Screw

Conduit

Chase

3/4 in.

(19 mm)

1¼ in.

(32 mm)

1¼ in.

(32 mm)

Direct Drive

Model Size

Curb Cap

Damper

Roof

Opening

*Approx.

Weight

060, 070

17

(432)

8

(203)

10

1

⁄

2

(267)

29

(13)

080, 090, 095

19

(483)

10

(254)

12

1

⁄

2

(318)

40

(18)

099, 101, 121, 131

19

(483)

12

(305)

14

1

⁄

2

(368)

67

(30)

141, 161

22

(559)

16

(406)

18

1

⁄

2

(470)

90

(41)

180, 200, 200HP

30

(762)

18

(457)

20

1

⁄

2

(521)

142

(64)

240, 240HP

34

(864)

24

(610)

26

1

⁄

2

(673)

175

(79)

300, 300HP

40

(1016)

30

(762)

32

1

⁄

2

(826)

313

(142)

• All dimensions are in inches

(millimeters)

. *Approximate weight shown in

lbs.

(kg.)

is the largest cataloged open drip proof motor.

• “Curb Cap” is the inside dimension of the curb cap

• The roof curb should be 1½ in.

(38 mm)

less than the curb cap to allow for

roofing and flashing.

• Roof opening is a square dimension.

1. On the roof surface,

cut an appropriate

sized hole and follow

manufacturer’s

instructions on curb

installation. Caulk and

flash the curb to ensure

a water tight seal.

2. If unit is equipped with

a backdraft damper, it

should be installed now.

3. Remove motor cover.

Access to the motor

compartment is

accomplished by

removing the screws as shown in Figure 3

,

page 2.

4a. On

belt drive

fans, use the lifting lugs on the drive

frame or bearing plate to lift and place the unit on

top of roof curb. Refer to Figure 2, page 2.

4b. On

direct drive

fans, lift and place the unit on

top of roof curb using hooks under the horizontal

supports. Refer to Figure 1, page 2.

5. Secure fan to curb using a minimum of eight lag

screws, metal screws or other suitable fasteners.

Shims may be required depending upon curb

installation and roofing material.

6. Verify power line wiring is de-energized before

connecting fan motor to power source.

7. For commercial kitchen and UL Listed emergency

smoke control applications, the electrical supply

must enter the motor compartment through

the breather tube. For other non-flammable

applications, the electrical supply can be routed

through the conduit chase between the curb cap

and the bottom of the motor compartment.

8. Connect power supply wiring to the motor as

indicated on the motor nameplate or terminal box

cover. Check the power source for compatibility

with the requirements of your equipment.

9. Check fan wheel for free rotation, recenter if

necessary. Check setscrew(s) for tightness.

10. Check all fasteners for tightness.

11. Mount and wire safety disconnect switch under

motor cover. Wire control switches at ground level,

refer to Figure 6.

12. Replace motor cover.

Figure 5 - Roof Curb Installation

Dimensional Data

Figure 6 - Typical Wiring Diagram

MOTOR

L1

115/208-230/60/1

208-230/460/60/3

MOTOR

J-BOX

J-BOX

SUPPLY VOLTAGE

SUPPLY VOLTAGE

L2

L1

L2

L3

Belt Drive

Model Size

Curb Cap

Shaft

Bearings

Damper

Roof

Opening

*Approx.

Weight

099, 101, 101HP,

121, 131

19

(483)

3

⁄

4

(19)

12

(305)

14

1

⁄

2

(368)

66

(30)

141, 141HP, 161,

161HP

22

(559)

3

⁄

4

(19)

16

(406)

18

1

⁄

2

(470)

87

(39)

161XP

22

(559)

1

(25)

16

(406)

18

1

⁄

2

(470)

87

(39)

180

30

(762)

3

⁄

4

(19)

18

(457)

20

1

⁄

2

(521)

126

(57)

180HP

30

(762)

1

(25)

18

(457)

20

1

⁄

2

(521)

126

(57)

200

30

(762)

3

⁄

4

(19)

18

(457)

20

1

⁄

2

(521)

142

(64)

200HP

30

(762)

1

(25)

18

(457)

20

1

⁄

2

(521)

142

(64)

220, 220HP, 240,

240HP, 240 XP

34

(864)

1

(25)

24

(610)

26

1

⁄

2

(673)

175

(79)

300, 300HP, 300XP

40

(1016)

1

(25)

30

(762)

32½

(826)

313

(142)

360, 360HP, 360XP

46

(1168)

1

1

⁄

4

(32)

36

(914)

38

1

⁄

2

(978)

440

(200)

420

52

(1321)

1

1

⁄

4

(32)

42

(1067)

44

1

⁄

2

(1130)

578

(262)

480

58

(1473)

1

1

⁄

2

(38)

48

(1219)

50

1

⁄

2

(1283)

675

(306)

• All dimensions are in inches

(millimeters)

. *Approximate weight shown in

lbs.

(kg.)

is the largest cataloged open drip proof motor.

• “Curb Cap” is the inside dimension of the curb cap

• The roof curb should be 1½ in.

(38 mm)

less than the curb cap to allow for

roofing and flashing.

• Roof opening is a square dimension.