Steel Grease Fan

10

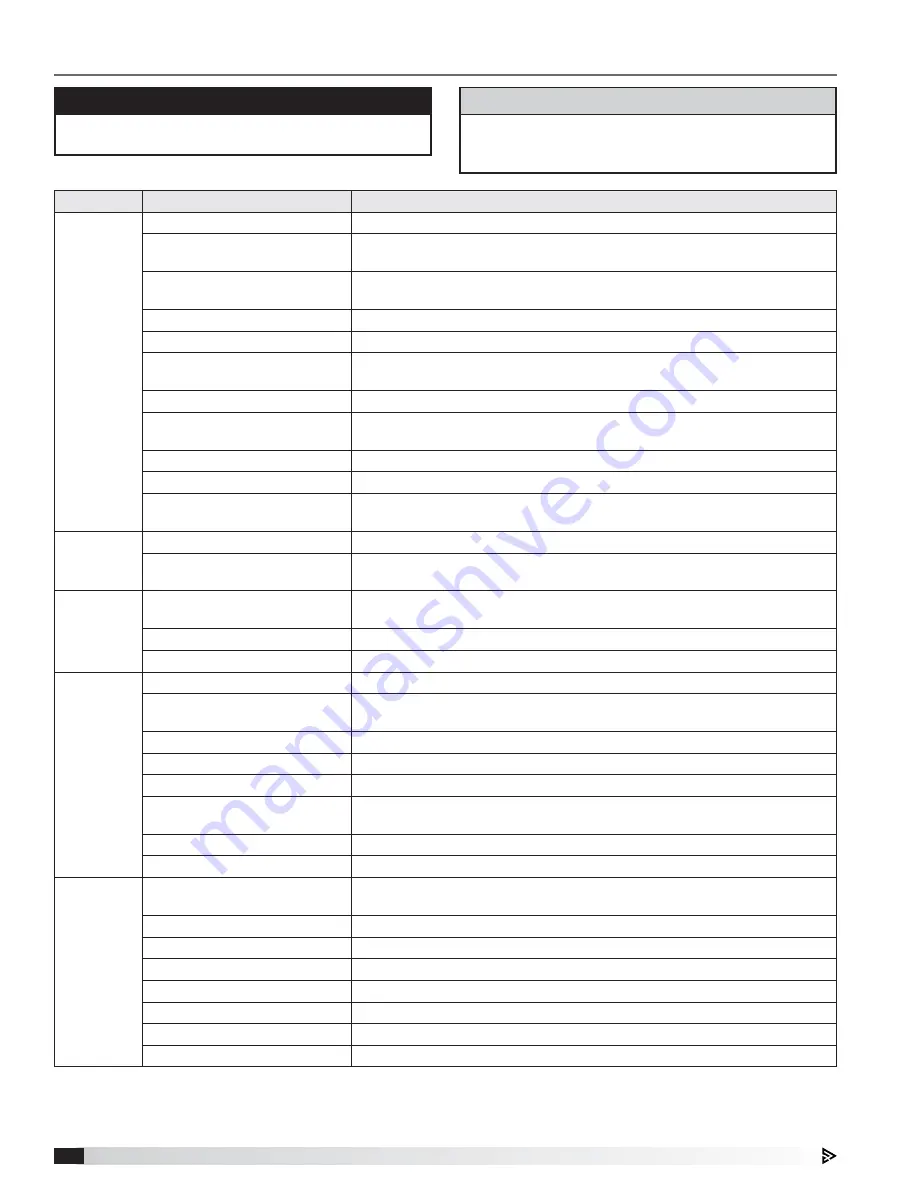

PROBLEM

CAUSE

CORRECTIVE ACTION

Excessive

noise or

vibration

Wheel rubbing inlet

Adjust wheel and/or inlet cone. Tighten wheel hub or bearing collars on shaft.

V-belt drive

Tighten pulleys on motor/fan shaft. Adjust belt tension. Align pulleys properly,

see page 6, Figures 10 and 11. Replace worn belts or pulleys.

Bearings

Replace defective bearing(s). Lubricate bearings. Tighten collars and

fasteners.

Wheel unbalance

Clean all dirt off wheel. Check wheel balance, rebalance in place if necessary.

Belts too tight or too loose

Adjust tension, see page 6, Figures 12 and 13.

Wheel improperly aligned and

rubbing

Center wheel on inlet, page 6, Figure 8.

Loose drive or motor pulleys

Align and tighten. See Pre-Starting Checks, page 6.

Foreign objects in wheel or

housing

Remove objects, check for damage or unbalance.

Fan base not securely anchored

Secure properly.

Motor hood loose and rattling

Tighten fasteners to secure motor hood.

Defective or loose motor

bearings

Replace motor with same frame size, RPM-HP.

High

horsepower

Fan

Check rotation of wheel, see page 6, Figure 9. Reduce fan speed.

Duct system

Resize ductwork. Check proper operation of face and bypass dampers. Check

filters and access doors.

Fan doesn’t

operate

Electrical supply

Check fuses/circuit breakers. Check for switches off. Check for correct supply

voltage.

Drive

Check for broken belts. Tighten loose pulley or belts.

Motor

Ensure motor is correct horsepower and not tripping overload protector.

Motor

overloads or

overheats

Lubrication

Check for excessive or insufficient grease in the bearing.

Mechanical

Replace damaged bearing. Relieve excessive belt tension. Align bearings.

Check for bent shaft.

Belt slippage

Adjust tension or replace bad belts, see page 6.

Over/Under line voltage

Contact power company.

Incorrect wheel rotation

Check motor wiring, see page 4, Figure 3.

Wheel RPM too high

Check drives or slow down fan by opening variable pitch pulley on motor

shaft.

Undersized motor

Check motor ratings with catalog speed and air capacity chart.

Motor wired incorrectly

Check motor wiring to wiring diagram located on fan motor.

Reduced

airflow

System resistance too high

Check system: Proper operation of backdraft or control dampers, obstruction

in ductwork, clean dirty filters.

Unit running backwards

Correct as shown on page 6, Figure 9.

Excessive dirt buildup on wheels

Clean wheel.

Improper wheel alignment

Center wheel on inlets, see Pre-Starting Checks, on page 6.

Dampers closed

Inspect and repair.

Blocked duct/clogged filter

Clean or replace.

Belt slippage

Replace and adjust tension.

Speed to slow

Check for correct drives.

WARNING

Before taking any corrective action, make certain unit

is not capable of operation during repairs.

AVERTISSEMENT

Avant d’entreprendre toute action corrective, s’assurer

que l’appareil ne pourra pas fonctionner durant les

réparations.

Troubleshooting