Steel Grease Fan

4

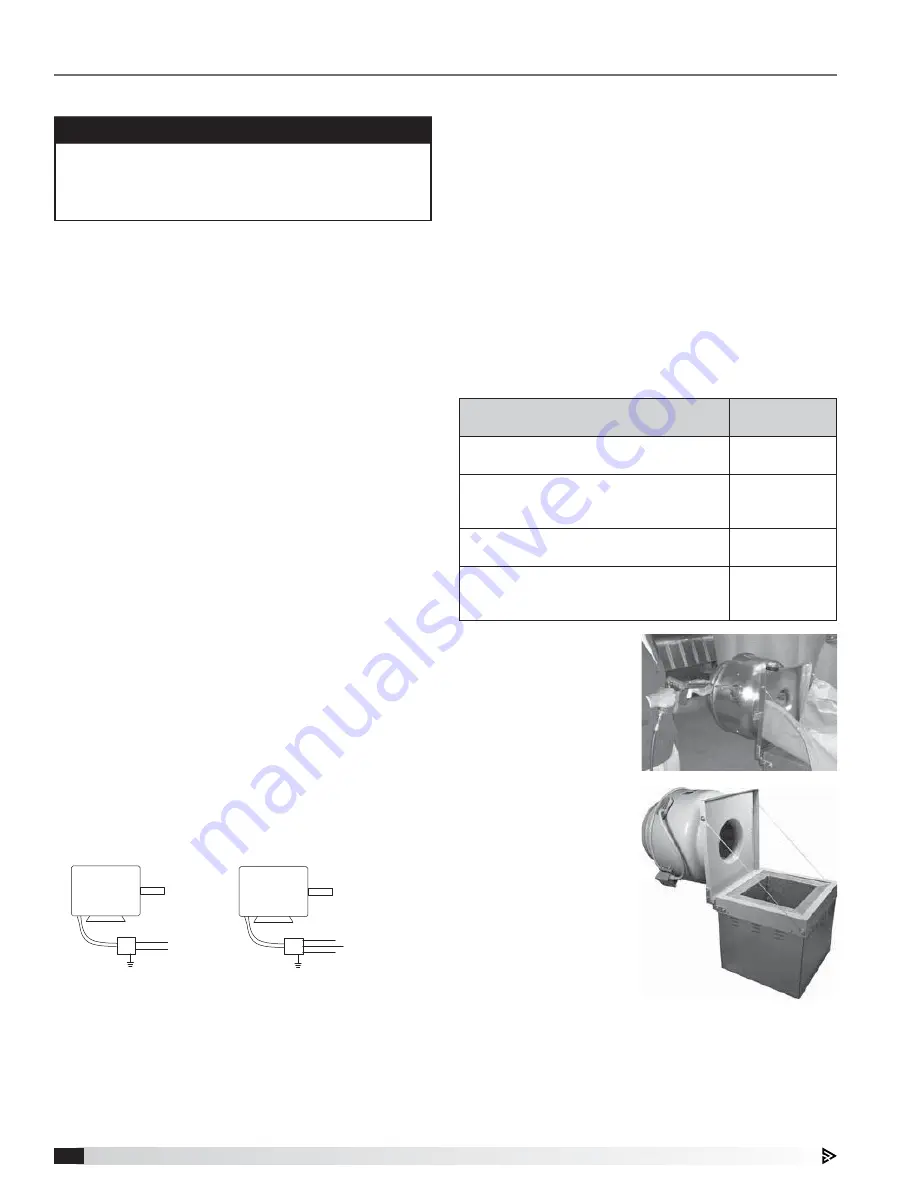

Figure 5

15. Hinged Base:

During installation

of the hinged base,

it is important not

to allow the fan to

go beyond 90º, see

Figure 5.

Table 1: Exhaust System Inspection Schedule

Type or Volume of Cooking

Frequency

Check

Systems serving solid fuel cooking

operations

Monthly

Systems serving high-volume cooking

operations, such as 24 hour cooking,

char broiling, or wok cooking

Quarterly

Systems serving moderate-volume

cooking operations

Semiannually

Systems serving low-volume cooking

operations, such as churches, day camps,

seasonal business, or senior centers

Annually

Figure 4

14. Clean-Out Port:

Position the

clean-out port so

it is on the side of

unit when hinged

open, see Figure 4.

Installation

Typical Roof Mounting Installation

1. On the roof surface, cut an appropriate sized hole

and follow manufacturer’s instructions on curb

installation. Caulk and flash the curb to ensure a

water tight seal.

2. Remove motor cover. Access to the motor

compartment is accomplished by removing the

screws as shown on page 2, Figure 2.

3. Use the lifting lugs on the drive frame to lift and

place the unit on top of roof curb. Refer to page 2,

Figure 1.

4. Secure fan to curb using a minimum of suitable

fasteners. Shims may be required depending upon

curb installation and roofing material.

5. Verify power line wiring is de-energized before

connecting fan motor to power source.

6. For commercial kitchen applications, the electrical

supply must enter the motor compartment through

the breather tube. For other non-flammable

applications, the electrical supply should also be

routed through the breather tube.

7. Connect power supply wiring to the motor as

indicated on the motor nameplate or terminal box

cover. Check the power source for compatibility

with the requirements of your equipment.

8. Check fan wheel for free rotation, recenter if

necessary. Check set screw(s) for tightness.

9. Check all fasteners for tightness.

10. Mount and wire safety disconnect switch under

motor cover. Wire control switches at ground level,

refer to Figure 3.

11. Replace motor cover.

MOTOR

L1

115/208-230/60/1

208-230/460/60/3

MOTOR

J-BOX

J-BOX

SUPPLY VOLTAGE

SUPPLY VOLTAGE

L2

L1

L2

L3

Figure 3 - Typical Wiring Diagram

IMPORTANT

Installation, troubleshooting and parts replacement

are to be performed only by qualified personnel.

Consult and follow all applicable national, state and

local codes as they will supercede this document.

12. A drain trough is provided on all fans for single-

point drainage of water and residue. Some means

for collection of this residue must be provided,

either a container directly under the trough or use

of an adapter and pipe to carry the residue to a

remote collection point. An optional grease trap

with water separator baffle is available from your

representative.

13. A clean-out port and hinged base are also provided

on all units. They aid the cleaning process through

additional access to the wheel. The fan is designed

for the worst cooking conditions, such as char

broilers, solid fuel cooking or oriental cooking.

Table 1 shows the suggested exhaust system

inspection schedule published in NFPA 96.