Steel Grease Fan

5

Commercial kitchen installations must comply with

NFPA 96. Check local and national codes for these

installations and consult local code authorities for other

specific requirements.

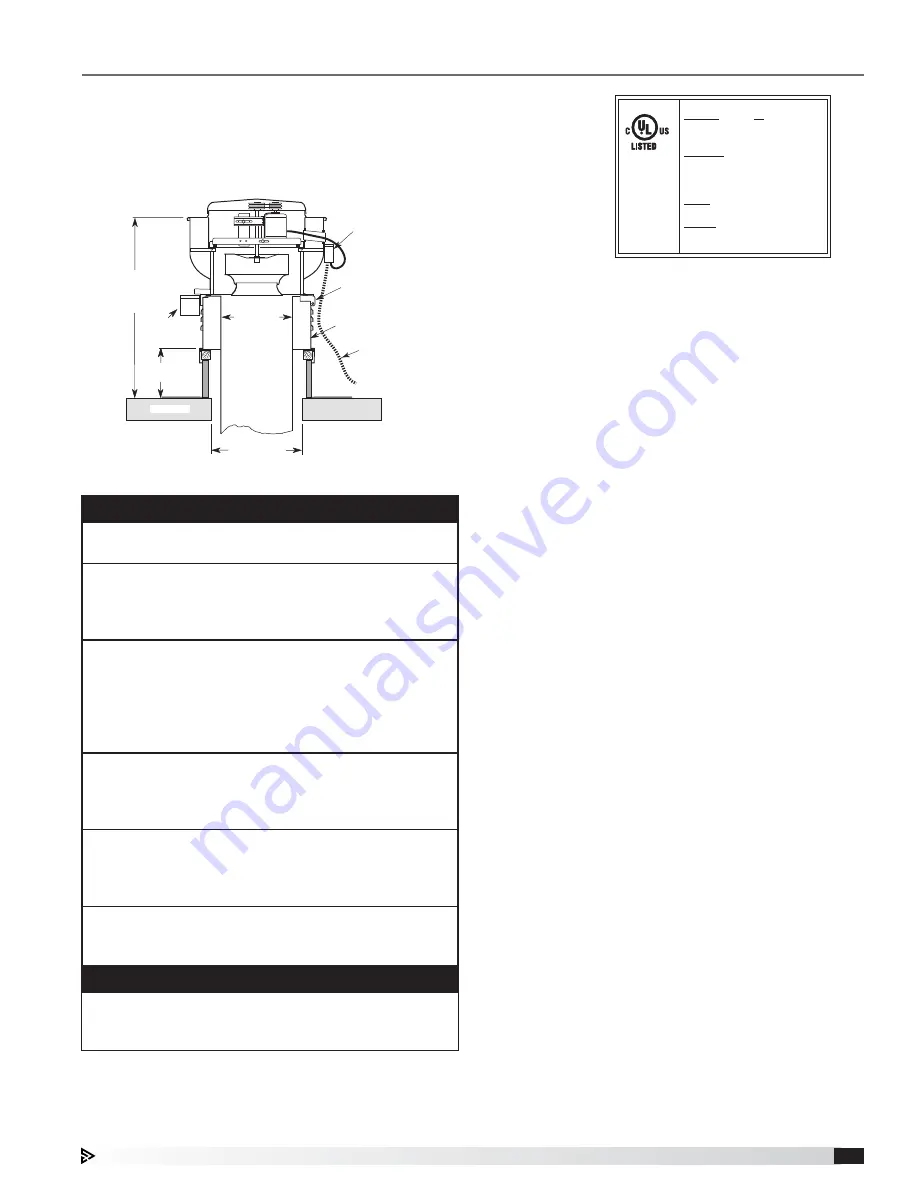

Perform steps 1-15: Typical Roof Mounting Installation.

Commercial Kitchen Installation

NEMA 3R

Disconnect

wired to

motor

through

breather tube

Recommended

Roof Opening

Roof Deck

Minimum 40 in.

(1016 mm)

Discharge

Height

8 in.

(203 mm)

minimum

Grease

Trap

Optional Vented

Curb Extension

Hinged Base

External Wiring

Liquid Tight

Flexible Conduit

(by others)

Welded Duct

(by others)

Minimum of

18 in.

(457 mm)

above roof deck

per NFPA

Figure 6 - Typical Roof Mounting Installation

461546

Power

Ventilator

Restaurant

Exhaust

Appliances

13G3

Maximum

Operating

Temperature

400°F

–Important–

ELECTRICAL

– If fan motor is NOT thermally protected, remote

overload protection must be installed having adequate rating as to

voltage, frequency, horsepower, and full load current per phase.

Where connected to a circuit protected by fuses, use time delay fuses.

For supply connection use wires rated for at least 90°C (194°F).

INSTALLATION

– When connecting electrical power to this fan,

do not restrict motor movement for possible future belt or wheel

adjustment.

Must be installed in accordance with the requirements to NFPA 96 or

must have minimum clearances of zero inches to non-combustibles,

3 inches to limited combustibles, 18 inches to combustibles.

CAUTION

– Mount with the lowest moving part at least 8 ft

PDERYHÀRRURUJUDGHOHYHO1RWUHTXLUHGRQURRIPRXQWHG

ventilators or duct mounted ventilators provided with belt guards.

ATTENTION

– Monter la pièce mobile la plus basse à au moins

2,5 m au-dessus du niveau du sol. Non requis pour les ventilateurs

montés sur un toit ou pour les ventilateurs montés sur gaine avec

protège-courroie.

Representation of

UL Listed

Power Ventilator

Restaurant

Exhaust

Appliances

label

Grease Trap Installation

The polypropylene grease trap is designed to collect

grease residue and avoid drainage onto roof surface.

Follow all local codes, as well as the National Fire

Protection Agency (NFPA) where applicable.

NFPA 96:

Upblast fans shall have a drain directed to a

readily accessible and visible grease receptacle not to

exceed 1 gal.

(3.8L)

Refer to Document 476370

- Grease Trap Installation,

Operation and Maintenance Manual for parts listing and

specific installation instructions.

Grease Trap Maintenance

Regular inspection of grease trap is recommended.

Depending on the amount of grease discharged through

the fan, the grease trap should be cleaned regularly to

ensure proper operation.

• Check grease absorber (if included) every month.

Replace grease absorber after every cleaning and/

or as needed between cleanings.

• Replacement grease absorbers (Part No. 476084)

can be ordered from your local representative.

IMPORTANT

The size of the duct must be equal to or larger than

the inlet opening of the fan.

To comply with NFPA 96, the fan discharge must be a

minimum of 40 in.

(1016 mm)

above the roof surface

and a minimum of 10 ft.

(3048 mm)

from any building

air intake.

Per NFPA 96, ductwork to an upblast discharge

exhaust fan must be constructed of and supported by

carbon steel not less than No. 16 MSG

(1.52 mm)

or

stainless steel not less than No. 18 MSG

(1.21 mm)

in

thickness. Duct must also extend a minimum of 18 in.

(457 mm)

above the roof surface.

Ensure that a minimum of 500 ft/min of air velocity

through the duct is maintained per NFPA 96, clause

8.2.1.1, 2014 edition and UL 762, Issue #7, clause 6.2,

October 14, 2013.

The following accessories may be required by NFPA

96 depending upon installation: Grease Trap and

Vented Curb. 8.2.1.1, 2014 edition and UL 762, Issue

#7, clause 6.2, October 14, 2013.

The following accessories may be required by NFPA

96 depending upon installation: Grease Trap and

Vented Curb.

IMPORTANT

Minimum duct velocities must be maintained in

kitchen exhaust applications. If a speed controller is

used, ensure compliance with all applicable codes.