25

5 OPERATING INSTRUCTIONS

You will need to familiarize yourself with the different screens available on the Wood Runner computer.

Navigation to the various screens is selected by buttons on the Main screen.

5.1 MACHINE STARTUP

Check to see that you have completed all of the connections properly as outlined above and make

sure all personnel are clear of the

Hazardous Zone

. See Safe Operating Procedures section earlier

in manual.

Check to see that Gantry Brake has been released as described in Section 4.

Depress the E-stop button on the Operator Console to insure that the machine does not start.

Turn the Main Disconnect to the ON position.

Turn the safety lockout valve to the ON position. This is located on the Air Supply Assembly. Check

the main pressure gauge for proper 90 psi pressure setting and adjust the regulator if necessary.

Turn the key switch on the Operators Console to the ON position and wait for the Computer to

display the Main screen.

Adjust the Light Curtain alignment as covered in section 8.6 of this manual. A Light Curtain that is

not aligned properly will prevent the safety system from resetting and the machine from operating.

Enter the Hazardous zone and press the Pre-Reset button. You will now have 8 seconds to break

the Light Curtain beam and reset the system using the reset key switch. See section 6.4 for a

description of the Pre-Reset Button operation.

Turn the key switch to the Reset position momentarily and the Enable screen should be shown. If a

Reset does not occur recheck the Light Curtain and Brake Beam adjustment. Refer to section 6 on

the Safety system.

Read and follow the instructions on the Enable Screen and then touch the Enable button. Enabling

the system will put the machine in operational mode. This should power up the servomotor for the

Gantry and energize the air system. The Picking Head and Screw Motor cylinders will retract to

their upper position. The Enable screen will change to the Main screen if the machine successfully

enables. See the Troubleshooting Section if the enable fails.

Summary of Contents for Wood Runner

Page 5: ...5 ...

Page 36: ...36 ...

Page 37: ...37 ...

Page 54: ...54 ...

Page 55: ...55 10 DETAILED PARTS IDENTIFICATION WOOD RUNNER 10 1 RUNWAY ASSEMBLY ...

Page 58: ...58 10 3 RUNWAY DRIVE ASSEMBLY ...

Page 61: ...61 10 5 GANTRY ASSEMBLY ...

Page 62: ...62 GANTRY ASSEMBLY ...

Page 64: ...64 10 6 PICKING HEAD ASSEMBLY ...

Page 65: ...65 PICKING HEAD ASSEMBLY ...

Page 68: ...68 10 7 ELECTRICAL PANEL ASSEMBLY ...

Page 70: ...70 10 8 GANTRY ENCLOSURE ASSEMBLY ...

Page 72: ...72 10 9 CONSOLE ASSEMBLY ...

Page 73: ...73 CONSOLE ASSEMBLY ...

Page 75: ...75 10 10 AIR SUPPLY ASSEMBLY ...

Page 77: ...77 10 11 GANTRY VALVE ASSEMBLY ...

Page 79: ...79 10 12 GANTRY BRAKE ASSEMBLY ...

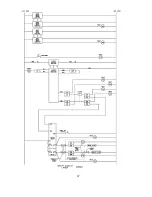

Page 81: ...81 11 ELECTRICAL DIAGRAMS 11 1 SYSTEM OVERVIEW ...

Page 82: ...82 11 2 MAIN ENCLOSURE LOW VOLTAGE ...

Page 83: ...83 11 3 GANTRY WIRING LOW VOLTAGE ...

Page 84: ...84 11 4 I O CHART ...

Page 85: ...85 11 5 INFEED WIRING LOW VOLTAGE ...

Page 86: ...86 11 6 OPERATORS CONSOLE ...

Page 87: ...87 11 7 MAIN ENCLOSURE HIGH VOLTAGE ...

Page 88: ...88 11 8 MAIN ENCLOSURE RECEPTACLE WIRING ...

Page 89: ...89 11 9 SAFETY CIRCUIT LAYOUT ...

Page 90: ...90 11 10 SAFETY CIRCUIT DIAGRAM ...

Page 91: ...91 11 11 BRAKE SENSOR DIAGNOSIS ...

Page 92: ...92 12 PNEUMATIC DIAGRAMS 12 1 SINGLE HEAD GANTRY ...

Page 93: ...93 12 2 DOUBLE HEAD GANTRY ...

Page 94: ...94 12 3 INFEED DECK ...