32

6.2 EMERGENCY STOP BUTTON

Located on the operators console next to the operators screen. Depressing the button causes an E-stop to

be triggered. Twist the button clockwise and pull slightly to reset it.

Emergency Stop Button & Keyed

Safety Pre-reset Button

Safety Reset Switch

6.3 KEYED SAFETY RESET SWITCH

This switch has 3 positions. “OFF” removes power from the operator’s console but does not remove power

from the Main Enclosure. “ON” boots the computer and powers other machine functions. “Reset” causes

the safety system to reset if the required conditions are met.

6.4 SAFETY PRE-RESET BUTTON

This button is located inside the HAZARDOUS ZONE. Its purpose is to protect personnel who are within the

HAZARDOUS ZONE by preventing a system safety reset by someone outside the HAZARDOUS ZONE. The

button must be pressed by the last person leaving the HAZARDOUS ZONE. After pressing the Pre-Reset

button you will have 12 seconds to break the light curtain upon leaving and reset the safety system using

the keyed reset switch on the operator’s console. If the reset switch is not operated within the required

time it will be necessary to push the pre-reset button and break the Light Curtain again. Never attempt to

reset the system if someone else is still within the HAZARDOUS ZONE as moving machinery could cause

serious injury or death. You will need to repeat the procedure if a reset does not occur within the 12

seconds. This timing is not adjustable. The Pre-Reset button is only necessary when the Light Curtain or

Brake Beam has been broken. An E-stop caused by the E-stop button can be reset without the Pre-Reset

button if the Light Curtain or Brake Beam has not been broken.

Summary of Contents for Wood Runner

Page 5: ...5 ...

Page 36: ...36 ...

Page 37: ...37 ...

Page 54: ...54 ...

Page 55: ...55 10 DETAILED PARTS IDENTIFICATION WOOD RUNNER 10 1 RUNWAY ASSEMBLY ...

Page 58: ...58 10 3 RUNWAY DRIVE ASSEMBLY ...

Page 61: ...61 10 5 GANTRY ASSEMBLY ...

Page 62: ...62 GANTRY ASSEMBLY ...

Page 64: ...64 10 6 PICKING HEAD ASSEMBLY ...

Page 65: ...65 PICKING HEAD ASSEMBLY ...

Page 68: ...68 10 7 ELECTRICAL PANEL ASSEMBLY ...

Page 70: ...70 10 8 GANTRY ENCLOSURE ASSEMBLY ...

Page 72: ...72 10 9 CONSOLE ASSEMBLY ...

Page 73: ...73 CONSOLE ASSEMBLY ...

Page 75: ...75 10 10 AIR SUPPLY ASSEMBLY ...

Page 77: ...77 10 11 GANTRY VALVE ASSEMBLY ...

Page 79: ...79 10 12 GANTRY BRAKE ASSEMBLY ...

Page 81: ...81 11 ELECTRICAL DIAGRAMS 11 1 SYSTEM OVERVIEW ...

Page 82: ...82 11 2 MAIN ENCLOSURE LOW VOLTAGE ...

Page 83: ...83 11 3 GANTRY WIRING LOW VOLTAGE ...

Page 84: ...84 11 4 I O CHART ...

Page 85: ...85 11 5 INFEED WIRING LOW VOLTAGE ...

Page 86: ...86 11 6 OPERATORS CONSOLE ...

Page 87: ...87 11 7 MAIN ENCLOSURE HIGH VOLTAGE ...

Page 88: ...88 11 8 MAIN ENCLOSURE RECEPTACLE WIRING ...

Page 89: ...89 11 9 SAFETY CIRCUIT LAYOUT ...

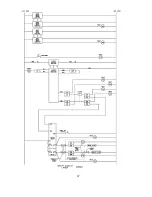

Page 90: ...90 11 10 SAFETY CIRCUIT DIAGRAM ...

Page 91: ...91 11 11 BRAKE SENSOR DIAGNOSIS ...

Page 92: ...92 12 PNEUMATIC DIAGRAMS 12 1 SINGLE HEAD GANTRY ...

Page 93: ...93 12 2 DOUBLE HEAD GANTRY ...

Page 94: ...94 12 3 INFEED DECK ...