Wire Rope Hoist

PAGE: 42

Model WR

WR-0214

2721 NE 4

th

Ave Pompano FL, 33064 | (954) 367-6116

Visit WWW.ACIHOIST.COM for the most current information

6.4 Tests

All new complete hoists, less trolley or trolleys, are load tested by ACI in accordance with ASME 830.16. Hoists furnished

in an uncompleted condition (i.e. Jess controls, less motor, less wire rope, etc.) as hoist components, and winch units

are not load tested by ACI. Therefore, it is the responsibility of the owner/user to load test the final lifting system using

such hoist components or winches in accordance with ASME 830.16. If the hoist is installed on a crane, load testing of

the crane in accordance with, as applicable, ASME 830.2, ASME 830.11, or ASME 830.17 may be required.

Testing of hoists after original installation is required when the hoist has been altered or repaired; has been idle for a

period of 12 months or longer; or in accordance with specific testing requirements established by the owner/user.

General testing requirements are outlined in ASME 830.16 and should be followed. ASME B30.16 lists two types of hoist

tests as follows:

1.

Operational test

2.

Load Test

ASME B30.16 uses the words

SHALL

and

SHOULD

in listing requirements, and defines these two words as follows:

SHALL -

indicates that the rule is mandatory and must be followed.

SHOULD -

indicates that the rule is a recommendation, the advisability of which depends on the facts in each

situation.

6.4.1 Operational Test

All altered or repaired hoists, or hoists that have not been used within the preceding 12 months,

SHALL

be tested by the

owner/user before being placed in operational service. The operational test is performed without a load on the hook and

includes: (1) operation of control devices; (2) lifting and lowering; (3) operation of brakes; and (4) operation and setting

of limit switch devices.

Operational test steps are as follows:

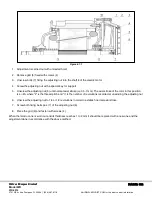

1.

Check hoist travel for correct hook motion (hoist motor is properly phased). Since motor rotation of a three-phase AC

motor can be changed by reversing any two of the lines feeding power to the motor, the direction of hook motion

must be checked to verify that it is correct in accordance with the hoist control device markings.

To check hook motion direction or motor phasing:

MOMENTARILY

activate the

UP

button or lever of the hoist control device and observe the direction of hook motion. If

direction of hook travel agrees with the direction marking of the hoist control device activated (i.e., hook direction is UP

when the hoist UP control device is activated), hoist motor is properly phased and proceed to step 5. If the direction of

hook travel does not agree with the direction marking of the hoist control device activated (i.e., hook direction is DOWN

when the hoist UP control device is activated), hoist motor is improperly phased and must be corrected. DO NOT USE

HOIST until motor phasing is corrected.

DO NOT operate hoist if direction of hook motion does not agree with the direction marking on the

hoist control device activated.

DO NOT attempt to correct an improperly phased hoist by changing any wiring in the hoist control

device or at the hoist contactors; or by changing the markings on the hoist control device.