MENU ADJUSTMENTS

1. Button definition

Set/Save

Bit Select/decrease

Adjust/increase

Users can adjust the parameters.

The backlight of LCD will be off after 30s without any key’s operation.

Note: the LCD will display "----" when the settings are successful, and display "Err" when failed.

2. Operation instruction

Users can adjust transmitter parameters. Push

button to enter programming. "P000" will be displayed. Push

button to select the Column and push

button to cycle 0-9 settings. Select different Codes to enter

corresponding parameter group settings.

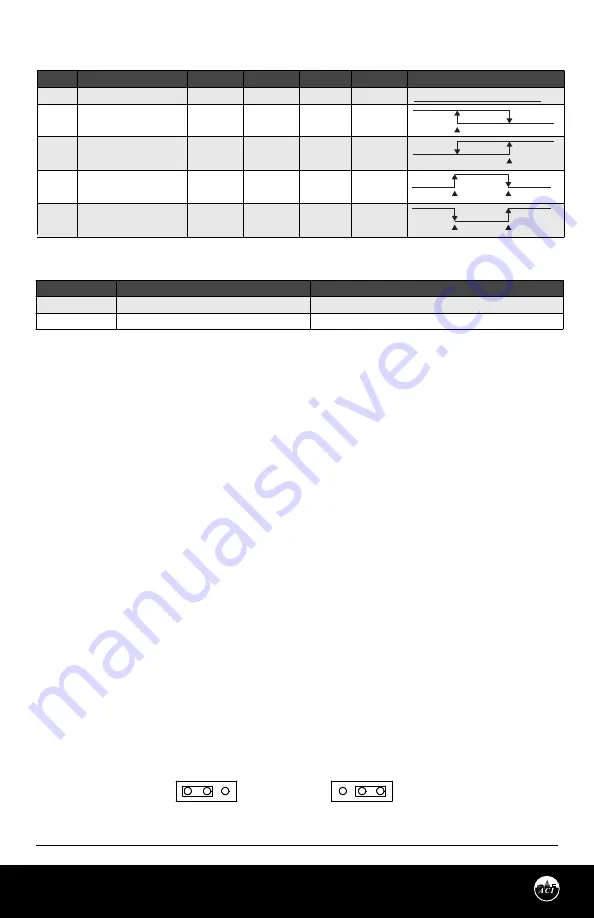

FIGURE 6:

EOL TERMINATION

Relays parameters and descriptions:

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone:

1-888-967-5224 |

Website:

workaci.com

Page 4

3. System Error signal

DEVICE CONFIGURATION THROUGH MODBUS RTU

MODBUS RTU INTERFACE

The Modbus Remote Terminal Unit (RTU) data link protocol uses EIA-485 as a two-wire, daisy chain

network. A branch is a discrete chain of devices connected to a controller. The max number of devices per

segment is (32), as per the Modbus specifications. 4000 ft (1219.2 m) is the maximum recommended length

for a segment, which includes all devices from the controller to the last device in the daisy chain.

Each branch must have all devices connected with (A) connected to (A) and (B) connected to (B). If a

shielded cable is used, this is not to be connected to the devices. The shield cable should only be

connected on one end to earth ground, usually at the controller.

Each device must be configured for the correct baud rate and have a unique address in each branch. The

baud rate for the branch is set by the controller.

EOL TERMINATION RESISTANCE SELECTION

RS-485 requires that the last device in a chain have a termination resistor. This is controlled using a jumper

in the center and right pins(120 Ω) position marked on FIGURE 7. When the jumper is set to 120 Ω, a 120 Ω

resistance is added in parallel to the data line. When the jumper is set to left and center pins(disabled), the

resistance is not added. By default, the jumper is placed in the disabled position.

A typical Modbus RTU mode message frame is shown below. In the Modbus RTU mode, the messages

between frames are separated by at least 3.5 characters time’s silent interval. If the silent interval between

two characters is more than 3.5 characters time, the former character was transferred successfully, and the

current character’s transmission starts.

ADDRESS SELECTION

Modbus can locate up to 256 different addresses, including valid addresses from 1-247. Address 0 is for

broadcast and address 248~255 are reserved for special addresses.

Slave address can be set with compatible Modbus RTU software or via Menu selection(see above for Menu

Adjustments). Default address is 1.

BAUD RATE, DATABITS, PARITY, AND STOPBITS SELECTION

Baud rate is set to 9600, but can also be configured to 4800 via the register or via Menu selection(see above

for Menu Adjustments).

The device that requests information is called the Modbus Master and the devices giving the information

are Modbus Slaves. The Modbus sensors are slave devices and the number of Data Bits needs to be the

same as in the Master device configuration. ACI’s Modbus RTU sensors utilize 8 data bits during

communication exchange.

Parity default setting is NONE. Stopbit default setting is 1. Both settings can adjusted via the register or via

Menu selection(see above for Menu Adjustments).

FUNCTION

The function code is the second data in the frame. Valid function codes are from 0~127 (01H~7FH). See the

relevant Modbus standard. It supports 03H/06H function codes, shown as the following Modbus Poll

software. The detail register addresses are in: 6 General registers table.

BROADCAST MODE TO WRITE DATA TO SLAVE

Using broadcast mode, customer can write data to all slaves connected to the network. Address of

broadcast mode to write data is 0.

For example: change slave address with broadcast mode, customer can set a new slave address. Note: since

this operation will modify all the addresses of the slavers to the same address, it is NOT applicable for

network of more than one slave.

ERROR CODE

Err

Er4

POSSIBLE PROBLEMS

Key input error

The sensor’s reading is abnormal

SOLUTION

Input correct code

Check if the sensor is in good connection with the PCB

J8

120Ω

END OF LINE

TERMINATION DISABLED

END OF LINE

TERMINATION ENABLED

J8

120Ω

Mode

0

1

2

3

4

Mode Description

Disable Relay

Activate Relay Below

Set Point

Activate Relay Above

Set Point

Activate Relay Between

High and Low Limits

Activate Relay Outside

High and Low Limits

PARA. #1

N/A

Set Point

Set Point

Low Limit

Low Limit

PARA. #2

N/A

Dead

Band

Dead

Band

High Limit

High Limit

PARA. #3

N/A

Actuate

Delay(S)

Actuate

Delay(S)

Actuate

Delay(S)

Actuate

Delay(S)

PARA. #4

N/A

Restore

Delay(S)

Restore

Delay(S)

Restore

Delay(S)

Restore

Relay(S)

Definition

Relay OFF

Relay ON

Relay ON

Relay OFF

Relay OFF

Relay OFF

Low limit

High limit

Dead band

Set point

Relay OFF

Relay ON

Dead band

Set point

Relay OFF

Relay ON

Relay ON

Low limit

High limit

SPECIAL MODE TO READ DATA FROM SLAVE

With the special mode, customer can read the register data under the circumstance of NOT knowing the

slave address.

Address of special mode read data: 255(0xFF)

Note: this operation is applicable for ONLY ONE slave in the network.

Version: 1.0

I0000941