Unit

Specifications

and Featur

es

(A-3)

(B)

•

MANUAL button :

This button selects the mode in the following order: AUTO, FORCED COOL, OFF.

FORCED COOL mode :

In FORCED COOL mode, the Operation light flashes. The system will then

turn to AUTO after it has cooled with a high wind speed for 30 minutes. The remote control will be

disabled during this operation.

OFF mode :

When the display panel is turned off, the unit turns off and the remote control is

re-enabled.

Operation

indicator

Electric heating

indicator

( some models)

Timer

indicator

PRE-DEF indicator

(pre-heating/defrost)

Alarm indicator

Infrared

receiver

Timer

indicator

Alarm

indicator

PRE-DEF

(pre-heating/defrost)

indicator

Manual

button

Operation

indicator

LED

display

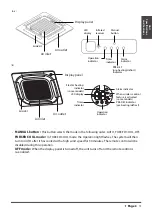

Air inlet

Air inlet

Air outlet

Air outlet

Louver

Louver

Display panel

Display panel

When wireless control

feature is activated

( some models)

LED display

Page

8