English –

2

ENEN

PRODUCT INSTALLATION

3

3.1 • Preliminary checks –

Application limits

Caution! – Before proceeding with installation,

verify the following.

- There are various versions of this product available, each

designed to manage a specific motor torque. Each is de-

signed to automate shutters / awnings / scre ens with spe-

cific dimensions and weight. Therefore, be fore proceed-

ing with installation, to check that the characteristics of

this motor (motor tor que, rotation speed and operating

time) are suitable for automating your shutter / awning

/ screen.

Caution! - Never install a motor with

a greater motor torque than that required to

move your shutter / awning / screen.

Check the diameter of the winding roller. This must be cho-

sen according to the motor torque, as follows:

- for motors that are size (Ø = 45 mm) and have a torque of

up to 30 Nm (included), the minimum inside diameter of

the winding roller must be 52 mm;

- for motors that are size (Ø = 45 mm) and have a torque of

up to 30 Nm (included), the minimum inside diameter of

the winding roller must be 60 mm.

for motors that are size (Ø = 58 mm), the minimum

inside diameter of the winding roller must be 70 mm.

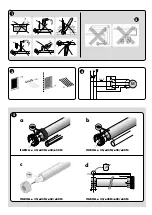

3.2 • Tubular motor installation

To install the product, follow the phases shown in

fig. 5

and

observe the following

warnings

:

- Incorrect installation can lead to serious injury.

ELECTRICAL CONNECTIONS

4

4.1 • Installing safety devices

in the electrical mains

In compliance with the electric installation rules, in the net-

work that powers the motor, a short circuit protection device

and a disconnection device from the mains electricity must

be envisioned.

Attention! – The disconnection device must al-

low the complete disconnection of the pow-

er supply, in the conditions established by the

over-voltage category III.

The disconnection device must be located in view of the au-

tomation and, if it is not visible, must envision a system that

blocks any accidental or unauthorised re-connection of the

power supply, in order to prevent any danger.

Note – The two devices are not present in the package.

4.2 • Installation of the

pushbutton strip

Recommendations:

• Position the push button control panel in view of the wind-

ing device but away from its moving parts.

• Position the push button control panel on the side of the wind-

ing device, where there is the electric cable coming from the

tubular motor and the mains electricity power supply cable.

• Position the buttons at a height over 1.5 m from the floor.

4.3 • Connecting the motor to a

control pushbutton panel

and the electrical mains

Attention!

• Incorrect connection can cause faults or dangerous situa-

tions, therefore scrupulously respect the instructions given

in this paragraph.

From an electrical perspective, the motor must be perma-

nently powered by means of a permanent connection to the

mains electricity (verify compatibility on the label attached

to the motor). To connect the motor to a push-button control

panel and the mains electricity, refer to

fig. 4

. The connec-

tion cable wires have the following function:

– Brown

= electric ascent or descent phase.

– Black

= electric ascent or descent phase.

– Blue

= Common (normally connected to the Neutral).

– Yellow-Green

= Ground (protective electrical bond-

ing).

4.4 • Associating the Up

and Down movements

with the respective

pushbuttons

On completion of connections, power up the motor and

check whether the Up and Down movements are associated

correctly with the relative control pushbuttons. If this is not

the case, invert the connection between the

Brown

and

Black

wires.