7. Cleaning and Maintenance

The unit must be cleaned periodically to optimize light output. Cleaning frequency depends

on the environment where the unit will operate: deposits of dust, smokes or other wastes

will reduce the light output performances.

Clean regularly the glass of the unit with soft cotton towel dampened with a

glass-cleaning liquid or distilled water.

Wash the housing with a soft brush or sponge and a mild, non-abrasive washing

detergent.

Remove smoke and other wastes by a cotton towel dampened with isopropyl alcohol.

Be careful when cleaning the components.

Always dry the parts carefully by a clean, soft, non-scratching towel or by compressed air.

Maintenance and service operations are only to be carried out by a qualified perso

DANGER!

Disconnect from the mains before starting any cleaning or maintenance work.

16B

Summary of Contents for BW-54-10FC II RL

Page 1: ......

Page 8: ...7B ...

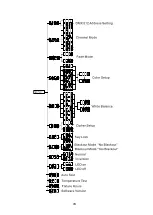

Page 13: ...5 3 DMX 512 Configuration 12B ...

Page 14: ...13B ...

Page 18: ...17B ...