15

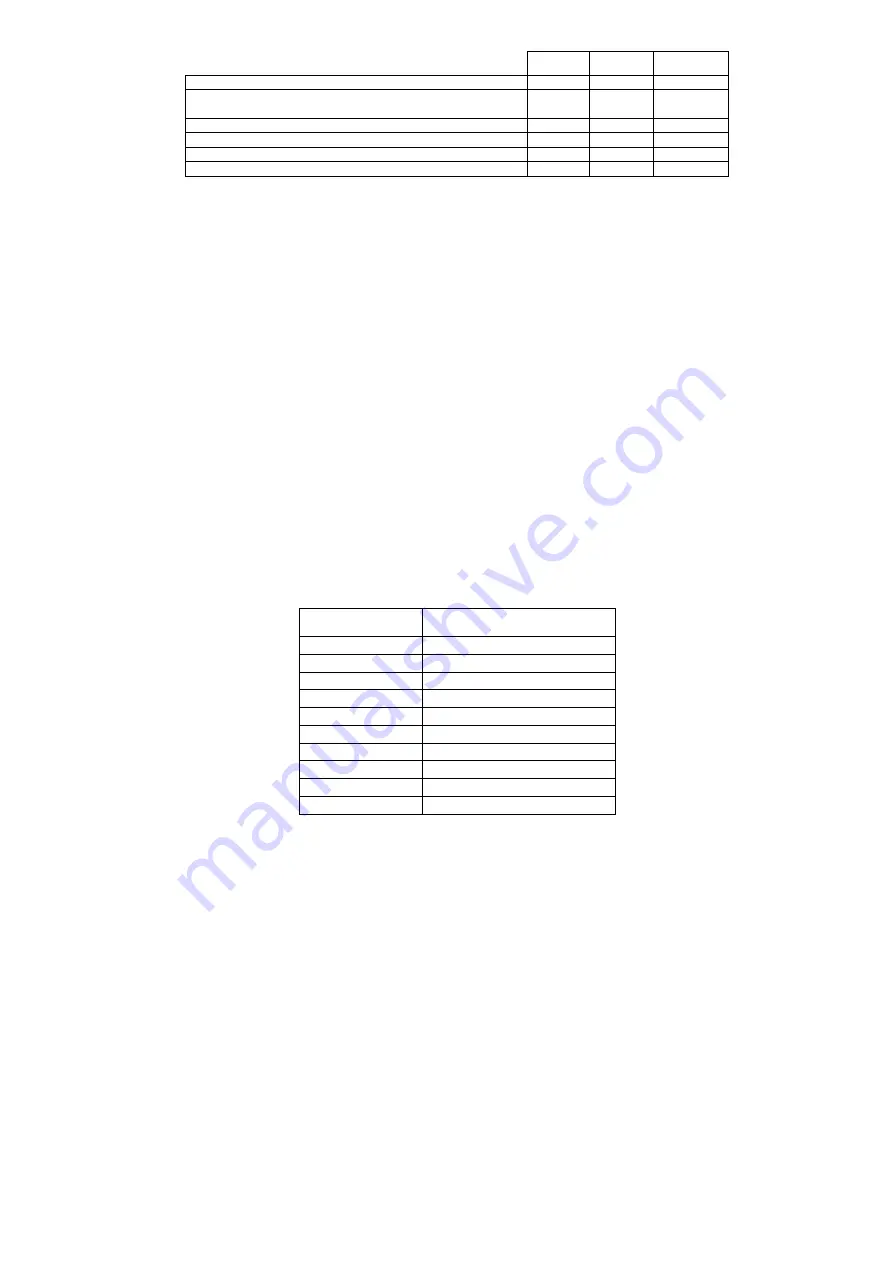

Minimal dimensions of sump [mm]:

width

length

height

AL-01NF, BF-01UNF, AL-05NF

600

750

700

AL-05LNF, AL-21NF, AL-31NF

BF-05UNF, BF-21UNF, BF-31UNF, BF-21PNF

650

800

750

AL-23ANF, AL-32ANF, AL-33ANF, AL-43ANF

900

1000

900

BF-32AUNF, BF-32APNF, BF-33AUNF, BF-33APNF

800

850

900

32GF21.0F, 32GF21.2F

750

1000

1060

SS-05AF, SS-21AF, SF-05AUF, SF-21AUF

700

900

880

6.2.5

Deaerate the sump tank or septic tank in accordance with the local rules and regulations.

6.2.6

When pumping from a reservoir where loose materials are sedimented, it is not suitable to put the pump on

these sediments as for one the pump will "bury" itself and then the functional surfaces of the hydraulic part will

get worn uselessly. In such case it is necessary to place pump on a fixed plate it is not possible to hang the

pump.

6.2.7

Do not place the pump in mud or sand. Do not allow the pump get clogged. In case of GF pump must not get

into the sump any abrasive particles because they quickly blunts the cutting device and the pump becomes

blocked.

6.2.8

A delivery hose or pipe must be connected to the delivery flange of the pump. The recommended materials the

hose should be made of are PVC, rubber etc. The pipe should be made of plastic or steel. The material must

always be resistant towards the medium being pumped.

6.2.9

Use only hoses and pipes of correct size, otherwise the hydraulic losses can become higher and the flow

capacity will be reduced. And in addition to this, the hose or pipe might get clogged.

6.2.10 For hanging the pump we recommend to use chain or steel rope. Load capacity of the chain or rope must be

chosen with respect to the pump weight (chapter 3.0) and additional load in the maximum immersion depth of

the pump in relation to the specific density of the liquid being pumped, so that the safety coefficient k > 3 is

observed. Larger pump sizes can not be hanging by handle. Material of the chain or rope must be resistant to

the pumped medium.

6.2.11 Pumps usually become warm. In order to avoid burns let the pump cool down after switching it off for about 20

minutes before you start to manipulate with it.

6.2.12 Do not let the pump run idle. The pump may get overheated and in such case you cannot file a claim.

6.2.13 The pipe can not be smaller than the pump discharge. The pipe must be able to convey medium with solid

particles. The flow speed in the delivery pipe must be sufficient enough for carrying any solid particles

dispersed in the liquid. In order to meet this requirement, the minimum speed of 0.6 m/s is required.

Pipe dimension

[mm] / [“]

Minimal flow rate

[lpm] / [m

3

ph]

32 / 1 ¼“

29 / 1,8

50 / 2“

84 / 5

80 / 3“

189 / 11,3

100 / 4“

320 / 19,2

150 / 6“

633 / 38

200 / 8“

1206 / 72,3

250 / 10“

1897 / 114

300 / 12“

2681 / 161

350 / 14“

3223 / 194

400 / 16“

4178 / 251

6.2.14 Is recomended to install ball-type check valve to discharge pipe to prevent from back flow and reverse rotation

of impeller. For type GF, it is necessary, otherwise the backflow would clog the cutting device by the cut

pieces.

6.2.15 The version fitted with the Guide Rail System consists of the GRS and the pump. The GRS is manufactured by

HCP PUMP MFR CO, LTD TAIWAN.