max. 12 cm

Assambly unit

ACO Light Shaft

for Pedestrian

Article No. 35595

plant.

h. Lay the surrounding paving around the

Light Shaft in a mortar bed.

Height adjustment for Light

Shafts 100 x 100 x 40 +

100 x 130 x 40

Prior to backfilling:

1. Loosen screws.

2. Position Light Shaft at the required

height (max. + 12 cm)

3. Retighten the screws.

4. Continue from instruction “f”

Assembly ACO Raising Element

(old model) pedestrian only:

1. Only possible after the Light Shaft has

been assembled.

2. Place the grid in the Raising Element.

3. Position stiffening frame in the Light

Shaft grid seat.

4. Adjust to the desired height by using the

Raising Element. The height can only be

adjusted using the lowest element.

5. Drill the holes.

6. Bolt the Raising Element into position.

7. Backfill carefully in layers with homoge-

neous material, and then compact as

described in instruction “f”.

8. Keep a proper distance away with the

vibrating plate, tamper and heavy plant.

9. Lay the surrounding paving around the

Light Shaft in a mortar bed.

Assembly ACO Raising Element

(old model) light vehicle:

Only possible with 40 cm deep Light

Shaft and with one element. Assemble

directly on cellar wall only. NOT possible

to assemble on insulation. Assemble in

accordance with the assembly instruc-

tions in fixing set Art.-No. 35908.

Assembly of the new ACO

Raising Element

Assemble in accordance with the

assembly instructions in the fixing set.

Important instructions:

• Light Shafts or Raising Elements. Do not

apply loads to Light Shafts or Raising

Elements before they are backfilled.

• Protect Light Shafts from falling objects

during the construction phase.

• During compaction, always place the

grid in position or use the stiffening

frame.

• The compacted soil may settle after

some time.

• Light vehicle Light Shafts should only

be driven over longitudinally (parallel to

the assembly wall). Completely driving

over the Light Shaft only possible in

agreement with the ACO Applications

Engineering Department.

Assembly instructions

Note: These assembly instructions to be read in conjunction with the sales brochure.

ACO Light Shaft

ACO Technologies plc

· Hitchin Road · UK-Shefford · Beds. SG 17 5TE

Tel. 00 44/14 62 81 66 66 · Fax 00 44/14 62 81 58 95 · technologies@aco.co.uk

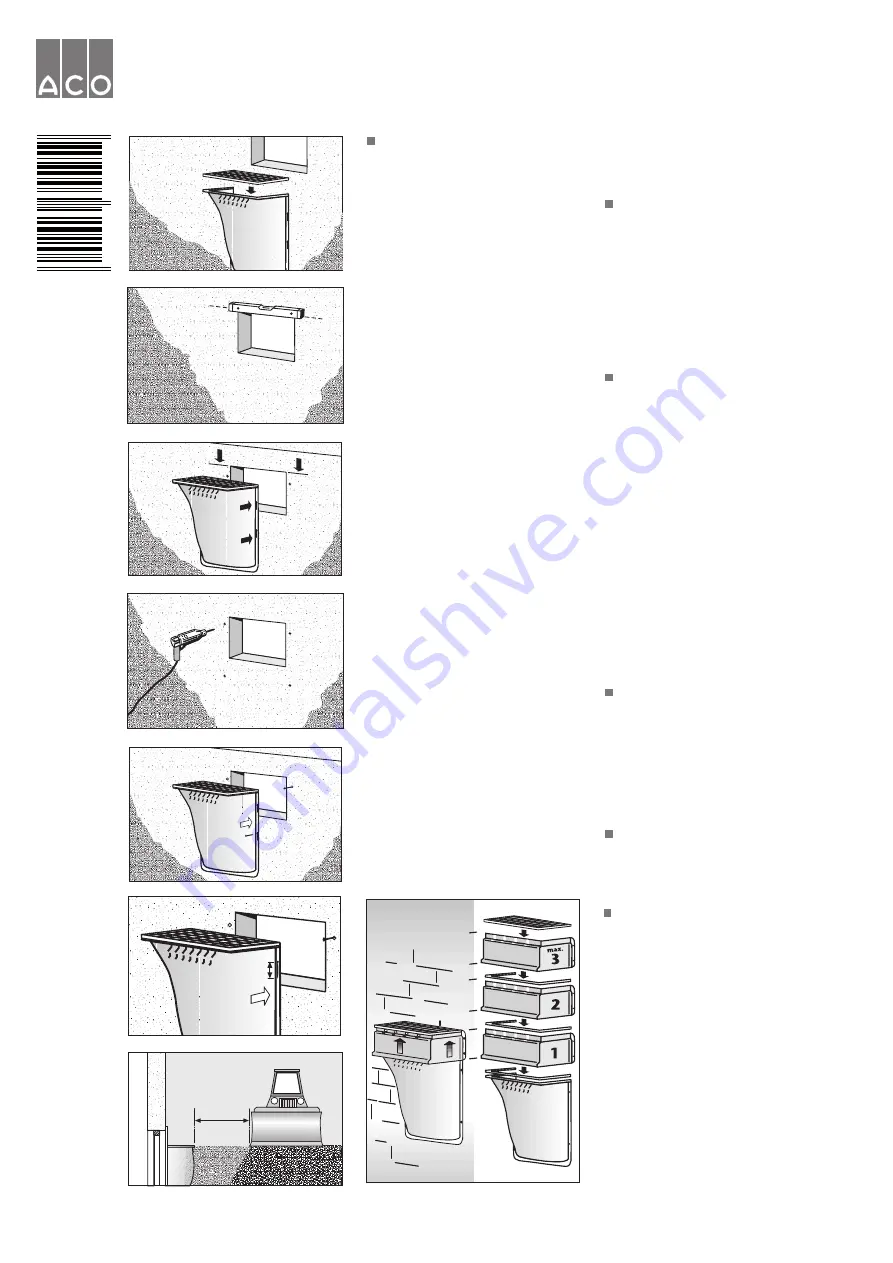

Assembly ACO Light Shaft for

pedestrian/light vehicle (a.-h.)

a. Before securing the Light Shaft in

position, insert the grid and fix the grid

fastener to the Light Shaft.

b. Mark the position of the unit so that the

top edge of the Light Shaft is equal to

the finished surface of the ground level.

When using the ACO assembly aid, the

upper edge of the assembly aid should

equal the top edge of the Light Shaft.

The distance between the lower edge

of the window to the base of the Light

Shaft should be at least 15 cm (pursu-

ant to DIN 18195).

c. Mark the two upper fixing holes with

inserted grid.

d. Drill the holes.

e.

Pedestrian model:

Insert the dowels,

and bolt on the Light Shaft. Use slotted

washers if necessary.

Light vehicle model:

The Light Shaft

must be installed directly on the cellar

wall. Bang in the heavy duty anchors

with the screwed on nuts. Remove the

nuts, hang in the Light Shaft, bolt on

with the washer and the nuts.

Assembly on insulation pedestrian:

Bang in the heavy duty anchors with the

screwed on nuts through the insulation

and into the cellar wall. Remove the

nuts, hang in the Light Shaft, bolt on

with the washer and the nuts. Then drill

the lower holes and fasten the Light

Shaft into position.

f. Backfill carefully in layers with homo-

geneous material, and then compact.

The grid has to be in position during

the compaction process. The distance

between the compactor and the Light

Shaft should become larger as each

higher layer is compacted. The top

layer around the Light Shaft should be

compacted manually. This should be

done in accordance with the regula-

tions in DIN 18300.

g. Keep a proper distance away with

the vibrating plate, tamper and heavy

9-29

37-58

65-86

a.

b.

c.

d.

e.

g.

h.

min. 1 m

40

02626

355959

e.2