10

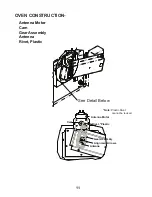

Oven Switch Replacement &

Interlock Switch Adjustment

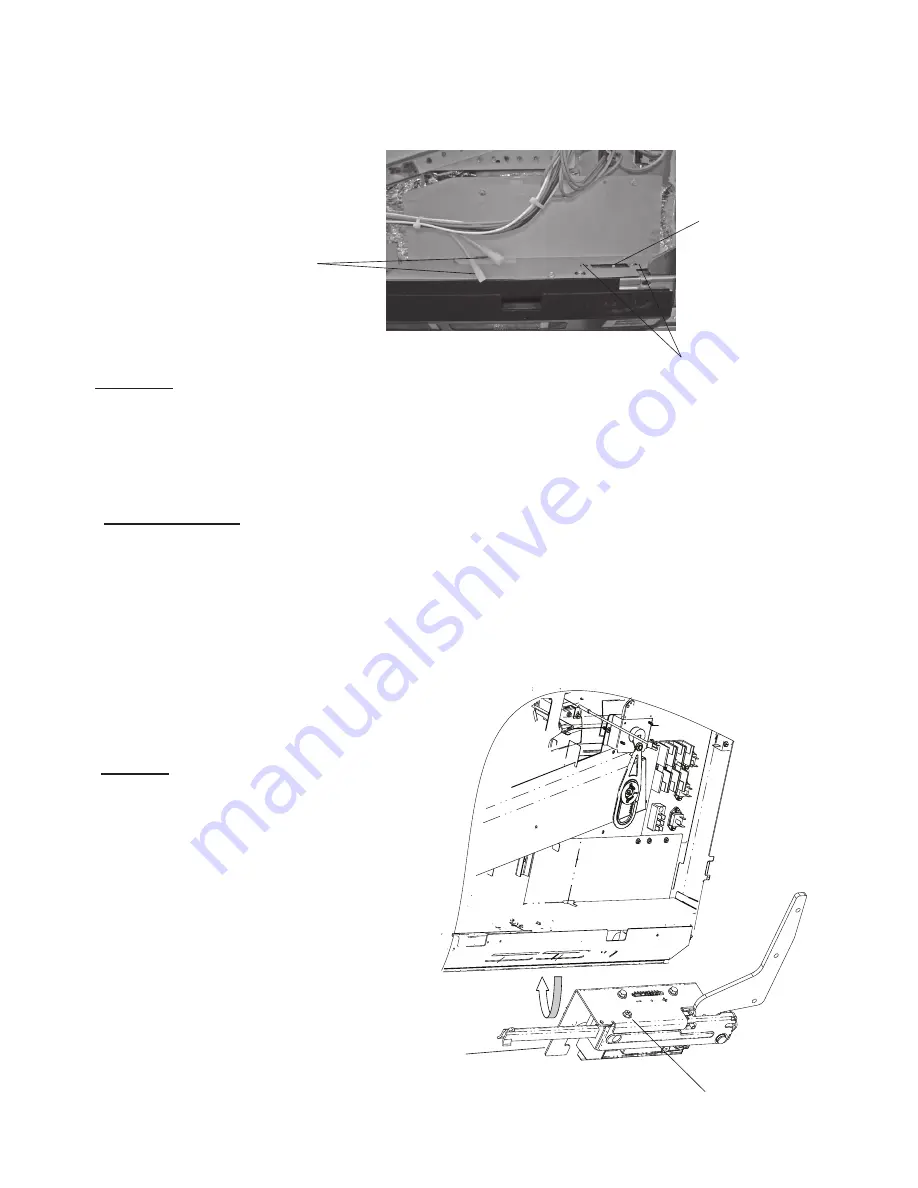

Figure 1

Attach Ohm-Meter to

Wire Harness Connectors

When the door is opened or closed, the left door hinge activates the secondary / monitor switches.

1. Connect an ohm-meter to wire harness (as shown in figure 1, to verify switch activation).

Note:

The switch assembly should activate when the door gap is approximately 1/4 inch (6mm).

Switch Adjustment:

Note:

Door closed for adjustment . Retightened screws before opening door.

1. Loosen slide adjustment mounting screws.

2. Slide adjustment lever for proper switch activation.

3. Tighten mounting screws.

4. Preheat oven to set temperature and verify switch adjustment settings and function.

Note:

To ensure proper switch adjustment, the switch mounting MUST be tightened after each adjustment

prior to testing the door alignment.

Removal:

1. Remove switch assembly

mounting screw.

2. Push switch assembly 1/2 inch (13mm)

towards back of oven.

3. Twist mounting leg towards

oven cavity to release mounting tab.

4. Push assembly towards back of oven

to remove.

Note:

New replacement switch assembly

has been adjusted at the factory, no adjustment

should be necessary.

Switch Test:

Switch Adjustment

Lever

Mounting Screw

Mounting Leg

Replacement

Adjustment

Slide Adjustment

Screws

OVEN CONSTRUCTION-