-

-

55

z

Decelerate to a stop.

2.3 CONSTANT INITIALIZATION AND LOCK PROTECTION

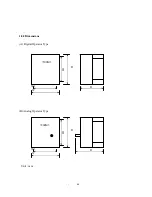

2.3.1 Constant Initialization(Operation to return to factory setting)

z

Write in 8 to constant (Pn-00)

Description

Key Operation

Digital Operator Display

Remarks

z

Frequency reference

value is displayed.

z

Select PRGM mode.

z

Select constant (Pn-00 )

z

Display Pn-00 data.

z

Change the set value.

z

Write in the set value.

(“End is displayed)

The data are displayed

LED DRIVE OFF

(Note 1)

Displayed for 0.5 second.

Confirm the display.

(Note 2)

Note : 1. Differs according to the setting data before changing

2.The display returns to 01 after write-in. This indicateds that initialization is executed at writing in

the data.

DSPL

RESET

DATA

STR

DRIVE

PRGM

DATA

STR

DSPL

JOG

DSPL

DSPL

RESET

DSPL

FWD

REV

RUN

STOP

STOP

RESET

DATA

STR

DRIVE

PRGM

DATA

STR

Turn on power

supply

○

1

Set Value

○

2

Pn-01

Pn-00

01

08

01