INSTALLATION METHOD 3 (timber framed buildings)

Where removal of any part of a timber frame is undertaken the structural integrity of the wall must be

retained. The advice of your local building control officer should be sought. If the property is under any

NHBC warranty it is also advised that their advice on this kind of modification is sought.

Either of the two preceding installation methods may be adapted for timber framed buildings, provid-

ing extra care is taken in ensuring combustible materials are adequately protected from the effects of

heat.

The appliance must be installed in accordance with the British Gas documents DM2 and DM3 or the

Institute of Gas Engineers published procedure document IGE/UP/7.

Special attention must be paid to the location of studwork frames of the inner leaf and the appliance

positioned accordingly. Wires and pipes that run within the wall must also be taken into account.

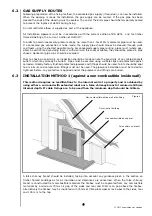

Installation as per method 1 (against inner wall)

When using this method of installation the following amendments should be incorporated. A 75mm air

gap or 75mm of

insulation (e.g.

rockwool) must be

provided between

combustible materi-

als and the sides

and rear of the cav-

ity box. A 100 mm

air gap or 100mm of

insulation (e.g.

rockwool) must be

provided to the top

of the cavity box. It

is also a good idea

to enable as much

airflow as possible,

into and out of the

area behind the fire

without excessive

heat loss from the

room when the fire is off.

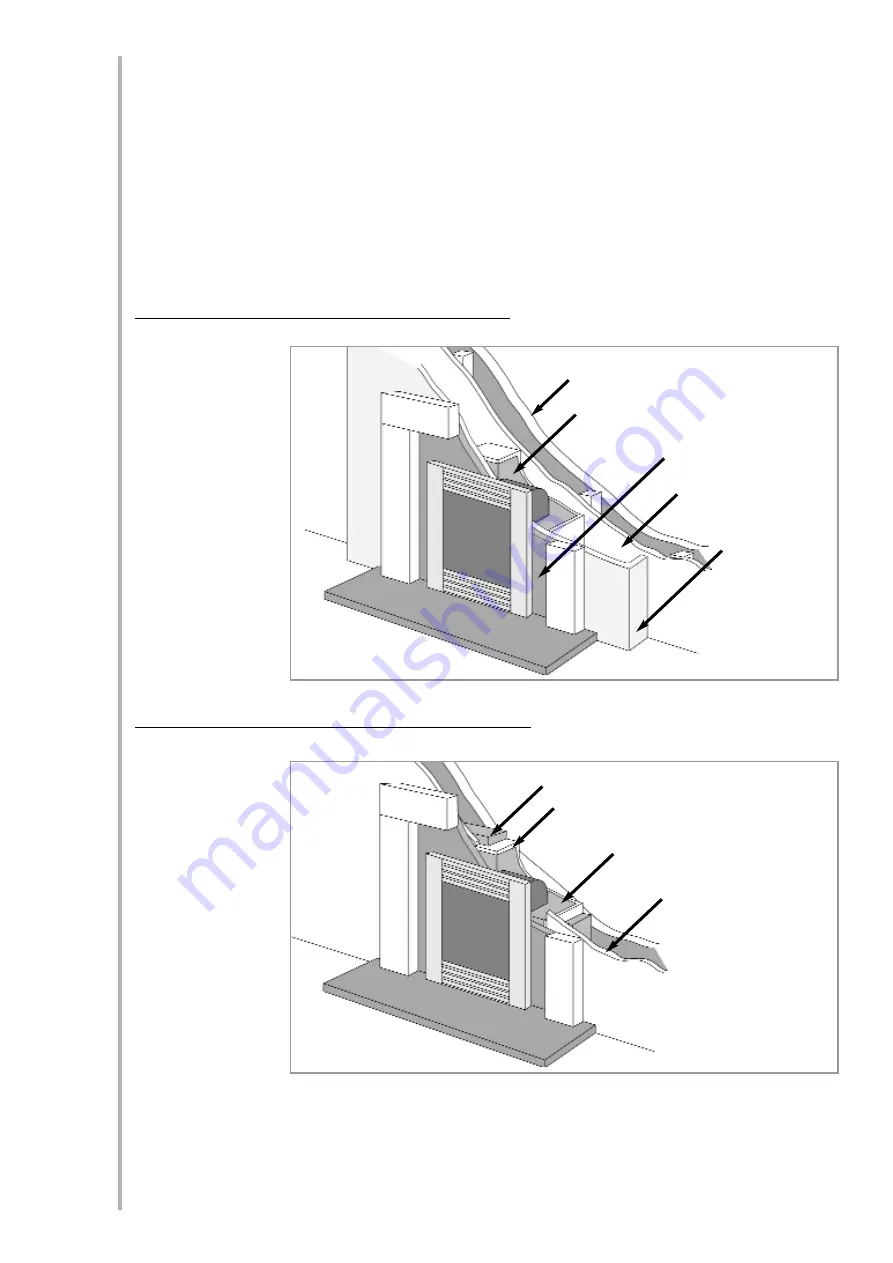

Installation as per method 2 (recessing into a wall)

When setting the appliance into the wall find a suitable position between frame timbers and open up

the hole. Secure

back the damp proof

membrane to pre-

vent ingress of

damp.

Again 50mm insula-

tion plus a 12mm

thick fire retardant

board, 'Superlux' or

equivalent, must be

provided between

combustible materi-

als and the sides

and rear of the cav-

ity box. 100 mm of

insulation plus a 12

mm thick fire retar-

dant board,

'Superlux' or equiv-

alent, must be provided to the top of the cavity box. The exposed cavity should be sealed off using non-

combustible board, ('Supalux' or equivalent), made into a 4-sided box. It is also good practice to fur-

ther insulate the cavity with a 50mm layer of Rockwool outside the Superlux box. Note that the appli-

ance should not be allowed to bridge the cavity in this installation method. It is also a good idea to

enable as much airflow as possible, into and out of the area behind the fire without causing excessive

heat loss from the room when the fire is off.

6.5

8

Figure 7

Outer leaf of building

Non combustible back panel

Combustible inside

wall of building

Rockwool insulation 75mm sides

and rear, 100mm top

False chimney breast

50mm of Rockwool to insulate cavity

Superlux Box, 12mm thick, External dims;

Height 677, Width 529mm, Depth 167mm.

Rockwool insulation, 50mm sides

and rear, 100mm top.

Combustible inside

wall of building

Figure 8

©

2011 Acquisitions of London