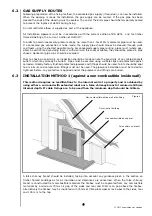

CHECKING THE BURNER AND SPARK GAP

There are no imitation fuel bed components to install. The appliance features a ribbon burner which is

designed to produce a continuous band of flame over it’s length. The burner should be visually inspect-

ed to ensure it is free from any foreign matter.

If it is necessary to clean or dust off the burner then (if fitted) the

glass door should be removed by removal of the four retaining

screws. Re-fit the glass door after cleaning or inspection, ensur-

ing a good seal.

The gap between the spark electrode and the pilot should be 3 -

5mm to produce a good spark. There should be no need to adjust

this. If under any circumstances the piezo electric spark fails, the

pilot cannot be lit manually.

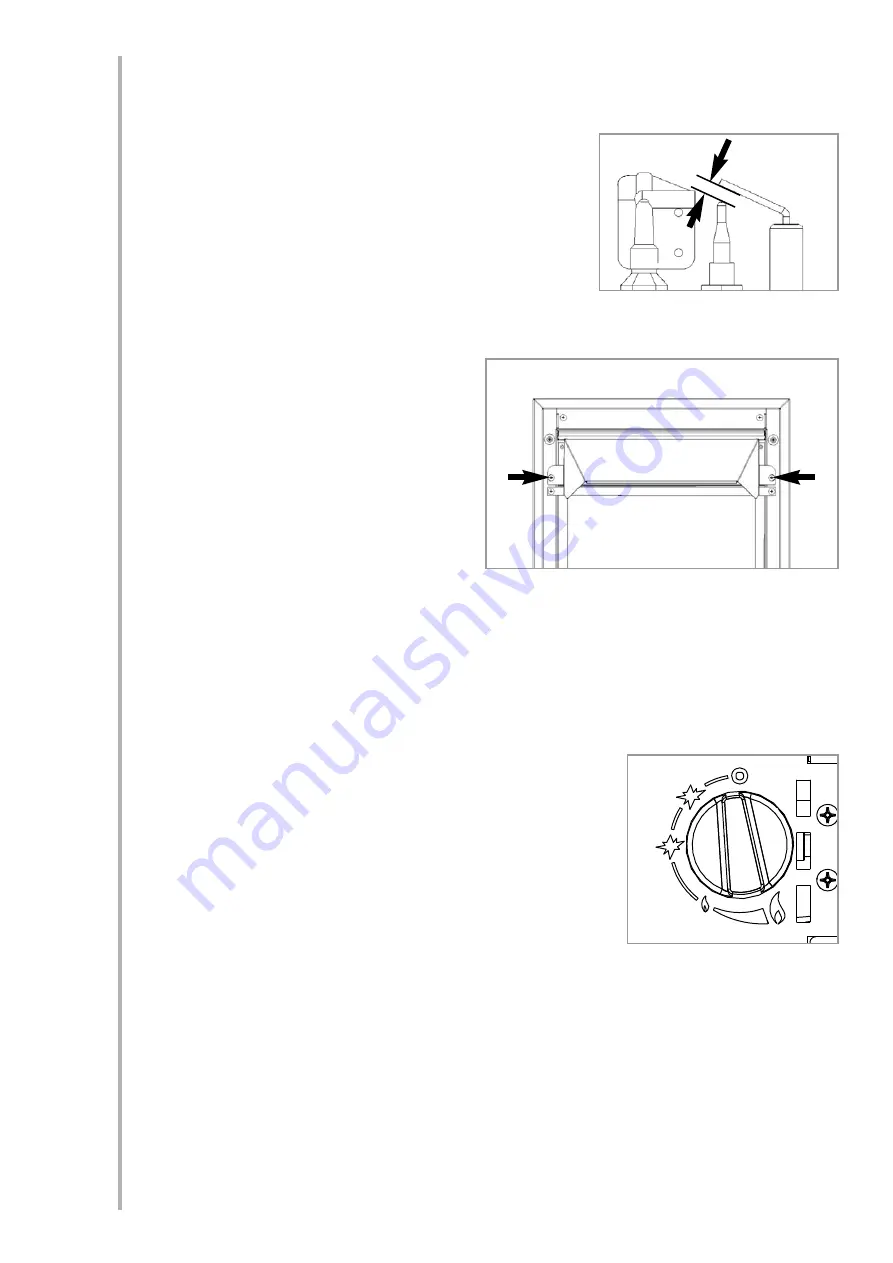

FITTING THE DECORATIVE FRAME, FRONT AND HOOD

The appliance is supplied with a decorative

frame and hood. Attach the hood using two M6

screws as shown in figure 13.

Remove all protective film from the frame. The

frame is retained by four magnets on the front

face of the firebox. Position the frame onto the

magnets.

IMPORTANT : Due to the possibility of sharp

edges, care should be taken when handling the

frame. The use of protective gloves is recom-

mended.

TESTING AND

COMMISSIONING

Turn on and test the gas supply up to the fire for any leaks, in accordance with the current edition of

BS6891.

OPERATING THE APPLIANCE

The control knob is supplied in the loose parts pack. Fit the control knob onto the valve spindle as shown

in figure 14.

The pilot is visible behind the left hand side of the burner. Push the control knob in fully and turn anti-

clockwise through both of the SPARK positions, keeping fully

depressed, hold there for a few seconds. If the fire has not been used

for some time, hold the knob in this position for longer, to allow any

air in the pipes to be purged.

Continue turning anti-clockwise through the spark clicks to the nine

o’clock position, ensuring the pilot has lit. If not, return the knob

clockwise, and repeat.

When the pilot lights after one of the two sparks, keep the knob

depressed in the nine o’clock position for approximately ten seconds.

Now release the knob and the pilot should stay alight. If the pilot is

extinguished during use, wait three minutes before repeating the ignition procedure.

To achieve the HIGH setting, push the control knob in slightly and continue turning anti-clockwise to

the high position. The main burner should light after a few seconds. To decrease the setting to LOW,

push the knob in slightly and turn the control knob clockwise to the low setting. To turn to the pilot only

position from the HIGH or LOW positions, press the control knob in, and return to the nine o’clock posi-

tion and release. To turn the fire OFF, keep the knob pressed in, return to the off position and release.

OPERATING PRESSURE

The pressure test point is located on the inlet restrictor elbow. Release the pressure test point screw,

and attach a pressure gauge.

10

7.2

Figure 12

Spark gap

©

2011 Acquisitions of London

Figure 13

7.3

8.0

8.1

8.2

Figure 14