Series 461A User's Manual Single/Dual Alarm

___________________________________________________________________________________________

- 4 -

Response Time: A built-in fixed time delay of 100 milliseconds

typical. That is, the relay will transfer

≤

100 milliseconds after

the input signal exceeds the setpoint. This delay helps prevent

false alarming due to transient interference. The relay will

transfer within 50mS after the input passes the deadband

region, as it returns into the normal range. The Red LED will

light as soon as the input signal exceeds the setpoint, but the

relay will not transfer until after the time delay has expired.

When calibrating the alarm, the LED's should be observed to

indicate proper setpoint position.

Noise Rejection - Common Mode: Better than 100dB at 60 Hz,

250

Ω

unbalance, typical. Normal Mode: 26dB at 60 Hz, 250

Ω

source, typical.

RFI Resistance: The unit will not trip under the influence of RFI

when the input is

±

0.5% of input span from the setpoint voltage

for RFI field strengths up to 10V/meter, at frequencies of

27MHz, 151MHz, and 467MHz.

EMI Resistance: Unit will not trip when input is

±

0.25% of input

span from the setpoint voltage with switching solenoids or

commutator motors.

Surge Withstand Capability (SWC): Input/Output terminations

are rated per ANSI/IEEE C37.90-1978. Unit is tested to a

standardized test waveform that is representative of surges

(high frequency transient electrical interference) observed in

actual installations.

Construction (Basic Alarm):

Printed Circuit Boards: Military grade FR-4 epoxy glass circuit

board, 0.063 inches thick.

Printed Circuit Board Coating: Fungus resistant acrylic

conformal coat.

Terminals: Compression type, wire size 14 AWG maximum.

Case: Self-extinguishing black NYLON Type 6.6 polyamide

thermoplastic, UL94 V-2. General Purpose, NEMA Type 1

enclosure.

Jumpers: Gold flash over nickel contacts.

Testpoints (Setpoint Voltage): Will accept up to an 0.080”

diameter probe tip. Do not insert probe tip more than 0.4” deep.

Mounting Position: Position insensitive.

MOUNTING:

-DIN: General Purpose Housing, DIN-Rail Mount - accepts both

"G" Rail (32mm), Type EN50035, or "T" Rail (35mm), Type

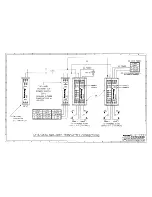

EN50022. Refer to Drawing 4501-252 for outline and

clearance dimensions. Shipping Weight: 1 pound (0.45 Kg)

packed.

CERTIFICATION: Consult the factory for current information on the

availability of agency (e.g. Canadian Standards Association,

Factory Mutual, etc.) approvals.

-NCR: No Certification Required.

INSTALLATION:

The alarm is packaged in a general purpose type of enclosure.

Use an auxiliary enclosure to protect against unfavorable

environments and locations. Maximum operating ambient

temperatures should be within -13 to 167oF (-25 to 75oC) for

satisfactory performance. Connect as shown in the Connection

Diagram 4501-542. To verify calibration, refer to the

"CALIBRATION" section.

Mounting: Mount alarm assembly - refer to Drawing 4501-540 for

mounting and clearance dimensions.

DIN Rail Mounting: Use suitable fastening hardware to secure

the DIN rail to the designated mounting surface. The alarm is

supplied with the DIN Rail mounting option (-DIN) and can be

mounted to either a "T" or "G" style rail. Installation of the alarm

to the rail depends on the type of DIN rail used. Units can be

mounted side by side on 1.6 inch centers, if required.

"T" Rail (35mm), Type EN50022: To attach an alarm to this

style of DIN rail, angle the top of the unit towards the rail and

locate the top groove of the adapter over the upper lip of the rail.

Firmly push the unit towards the rail until it snaps solidly into

place. To remove an alarm, insert a screwdriver into the lower

arm of the connector and pull downwards while applying

outward pressure to the bottom of the unit.

"G" Rail (32mm), Type EN50035: To attach an alarm to this

style of DIN rail, angle the unit so that the upper groove of the

adapter hooks under the top lip of the rail. Firmly push the unit

towards the rail until it snaps solidly into place. To remove an

alarm, pull the lower part of the unit outwards until it releases

from the rail and lift the unit from rail.

Electrical Connections:

The wire size used to connect the unit to the control system is

not critical. All terminal strips can accommodate wire from 14-26

AWG. Strip back wire insulation 1/4-inch on each lead before

installing into the terminal block. Input wiring may be shielded or

unshielded twisted pair. Since common mode voltages can exist on

signal wiring, adequate wire insulation should be used and proper

wiring practices followed. It is recommended that input wiring be

separated from relay contact wiring for safety, as well as for low

noise pickup.

1. Power (Refer to Drawing 4501-542 for power connections):

The label on the unit specifies the AC power requirements.

Connect AC power as shown in Drawing 4501-542. Use

suitable wire per applicable codes. For 115VAC units, connect

the AC HOT power lead to the (L1) terminal and the AC

NEUTRAL power lead to the terminal marked (W). For 230VAC

units, connect the AC L1 power lead to the (L1) terminal and AC

L2 power lead to the terminal marked (L2). Connect the AC

GROUND lead to the (G) terminal (the AC Ground (G) terminal

is not connected internally).

2. Grounding: The alarm housing is plastic and does not require

an earth ground connection. If the alarm is mounted in a metal

housing, a ground wire connection is required. Connect the

ground terminal of the metal housing (Green Screw) to a

suitable earth ground using appropriate wire per applicable

codes.