IntelliPack Series 892M/894M Computation Transmitter User's Manual DC Voltage/Current Input

___________________________________________________________________________________________

- 5 -

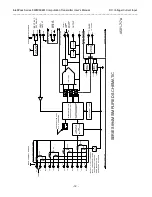

Jumper Installation (Voltage Output)

For voltage output, a short jumper must be installed between

the output “I+” and “JMP” terminals. A jumper wire is included

with the unit and has already been installed between the output

“I+” and “JMP” terminals as shipped from the factory. Verify the

position of this jumper if your application requires output voltage.

Remove this jumper for current output applications. Refer to the

Electrical Connections Drawing 4501-719.

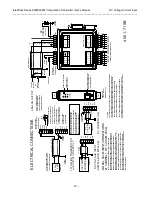

Mounting

Refer to Enclosure Dimensions Drawing 4501-720 for

mounting and clearance dimensions.

DIN Rail Mounting:

This module can be mounted on "T"

type DIN rails. Use suitable fastening hardware to secure the

DIN rail to the mounting surface. Units may be mounted

side-by-side on 1-inch centers for limited space applications.

"T" Rail (35mm), Type EN50022:

To attach a module to this

style of DIN rail, angle the top of the unit towards the rail and

locate the top groove of the adapter over the upper lip of the

rail. Firmly push the unit towards the rail until it snaps solidly

into place. To remove a module, first separate the input

terminal block(s) from the bottom side of the module to

create a clearance to the DIN mounting area. Next, insert a

screwdriver into the lower arm of the DIN rail connector and

use it as a lever to force the connector down until the unit

disengages from the rail.

Electrical Connections

Terminals can accommodate wire from 14-24 AWG (stranded

or solid copper). Strip back wire insulation 1/4-inch on each lead

before installing into the terminal block. Input wiring should be

shielded twisted-pair. Since common mode voltages can exist on

signal wiring, adequate wire insulation should be used and proper

wiring practices followed. It is recommended that transmitter

output and power wiring be separated from the input signal wiring

for safety, as well as for low noise pickup. Note that input, power,

and output terminal blocks are a plug-in type and can be easily

removed to facilitate module removal or replacement without

removing individual wires. If your application requires voltage

output, you must install a jumper between the output “I+” and

“JMP” terminals (pre-installed from the factory). Remove this

jumper for current output applications. If your input is process

current, you must also install a short jumper wire between the

input “I+” and “V+” terminals to complete the input circuit. Be

sure to remove power and/or disable the load before unplugging

the terminals to uninstall the module, installing or removing

jumpers, or before attempting service. All connections must be

made with power removed.

IMPORTANT

: Power, input, and output I/O wiring must be in

accordance with Class 1 Division 2 wiring methods, Article 501-

4(b) of the National Electrical Code, NFPA 70, for installations in

the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations within Canada and in accordance

with the authority having jurisdiction.

This equipment is suitable for use in Class I, Division 2,

Groups A, B, C, and D, or non-hazardous locations only.

CAUTION:

Risk of Electric Shock - More than one disconnect

switch may be required to de-energize the equipment before

servicing.

WARNING:

Explosion Hazard - Substitution of any

components may impair suitability for Class 1 Division 2.

WARNING:

Explosion Hazard - Do not disconnect equipment

unless power has been switched off or the area is known to be

non-hazardous.

1.

Power:

Refer to Electrical Connections Drawing 4501-719.

Variations in power supply voltage within rated limits has

negligible effect on module accuracy. For supply

connections, use No. 14 AWG wires rated for at least 75

C.

The power terminal is diode-coupled for reverse polarity

protection. Choose a power supply capable of providing the

maximum steady state current draw of the module, plus the

peak inrush current that is required when power is first

switched on, or startup problems may occur. As a general

rule, the peak current approaches twice the maximum steady

state current. Peak currents are reduced with higher supply

voltages.

2.

DC Voltage/Current Inputs:

Connect input(s) per Drawing

4501-719. Observe proper polarity (see label for input type).

An excitation supply is provided at the input for powering two-

wire transmitters. For process curren

t input, the input “I+”

must be jumpered to the input “V+” terminal. Place a short

jumper between these terminals to complete the input circuit

for current inputs only. Voltage is delivered to the “V+” input

directly with this jumper removed.

Optional HOLD Wiring:

A TTL or open collector/drain signal

may be wired to the HOLD and common (COM) terminals of

the module to

hold

the transmitter output at the last

computed value while HOLD is asserted low. HOLD is

pulled-up internally (deasserted) and is part of the input

circuit which is isolated from the output. HOLD common

(COM) and input return (RTN) are not equivalent potentials

and should never be tied together. Make sure that common

is not inadvertently tied to ground which may be connected to

input return.

3.

Analog Output Connections

: Wire outputs as shown in

Electrical Connections Drawing 4501-719. For voltage

output, you must also install a jumper between the output “I+”

and “JMP” terminals (pre-installed from the factory). Remove

this jumper for current output. Current is delivered directly

from the “I+” output with the jumper removed.

4.

Grounding:

See Electrical Connections Drawing 4501-719.

The module housing is plastic and does not require an earth

ground connection. However, there are mounting positions at

the output terminals to connect a cable shield, plus earth

ground. These connections are isolated from the internal

circuit and are recommended to minimize noise and help

protect the unit from damaging I/O transients.

WARNING:

For compliance to applicable safety and

performance standards, the use of shielded cable is

recommended as shown in Drawing 4501-719. Further, the

application of earth ground must be in place as shown in

Drawing 4501-719. Failure to adhere to sound wiring and

grounding practices may compromise safety & performance.