A

WO

A N N

1 W r i l .

*

1

I

t

A

0 I

V _I 44 I I I II I

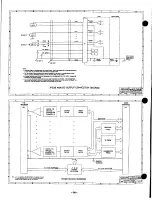

COMPONENT SIDE VIEW

ALMNI.LA A A A

0212!

POWER supply

SELECTION'

JI

(I k 2)

JI

(2 A 3)

..r2

(I Ik 1)

J2

(2 k 3)

4 4 - 1 2 VOLT (PrIERNAL. P I )

RI

OUT

N

OUT

AA- 1 5 WET (EXTEM01. P2)

COT

RI

OUT

RI

2

3

4

6

6

•

A

B

LOGIC INTERFACE

P1

I/O INTERFACE

P2

POWER SUPPLY SELECTIONS (PINS OF J1 AND J2)

•

*DERMAL

AND EXTERNAL SUPPLIES SHOULD NOT BE MIXED (E.G. DO NOT USE . 1 2 VOLis WITH - 1 5 VOLTS.)

C

IP220 JUMPER LOCATIONS

0

E

F

G

2

.3

4

5

AttOMOte r-tite-a A —

E V IC

02241 JUMPER LOCATION

r - P 2 2 4 i p t 4 5 0 1 - 4 4 1 I A Z

6

2

3

4

5

•

A

B

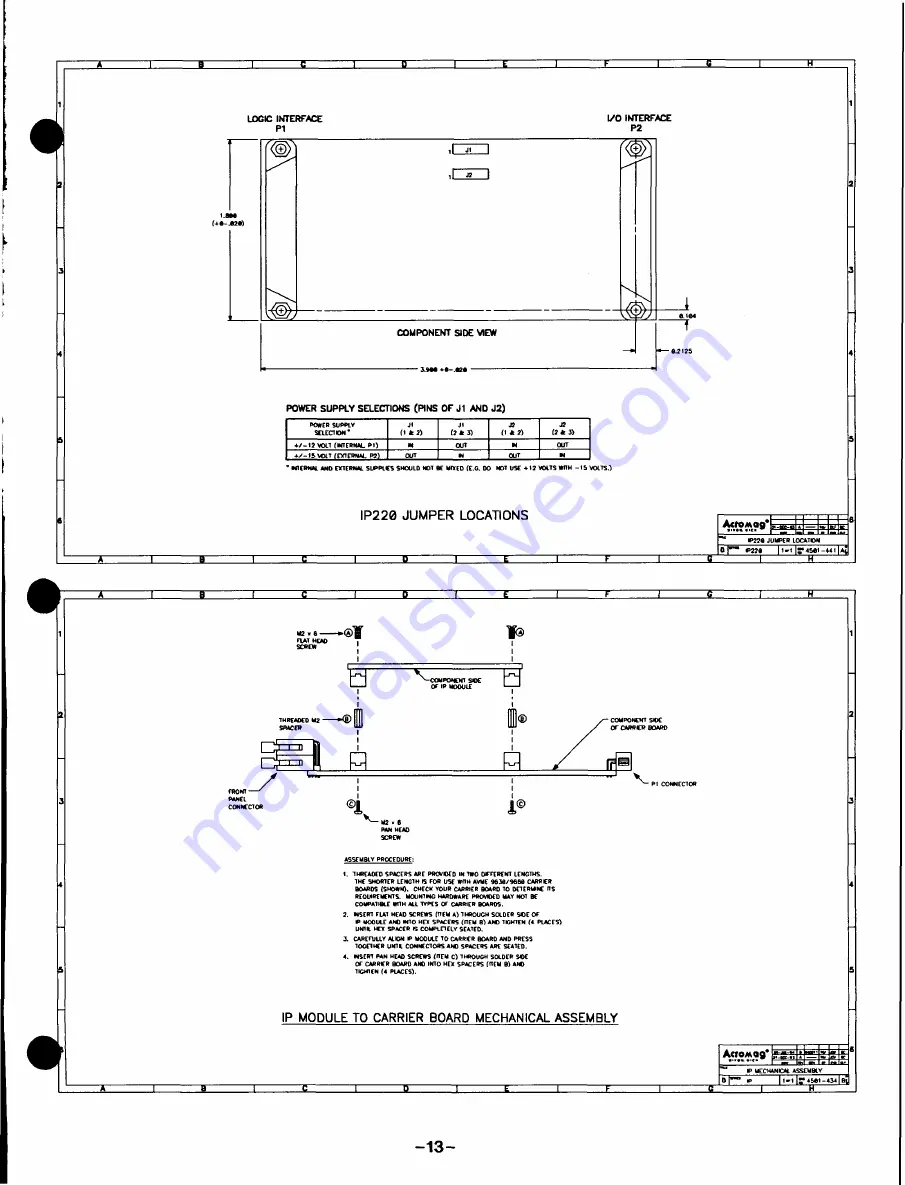

EROTO

PANEL

CONNECTOR

C

1

F

H

02

y B _ _ m i t ,

n.Arr HEAD

SCREW

` C O G E E

o r IP MODULE

THREADED Y2— R e I I [

SPACER

COMPONENT SIDE

OF CARRIER BOARD

/

IPN

* —

WE

y 6

POP HEAD

SCREW

ASSEMBLY PROCEDURE:

THREADED SPACERS ARE PROVIDED IN TWO DEFERENT LENGTHS.

THE

SHORTER

LENGTH IS FOR USE WOW

AWE % 3 0 / % 8 8 COPPER

(SHOWN). CHEER YOUR CARRIER BOARD TO DETERMINE DS

REoLAREMENTS. MOL0411NG IMRDWARE PROVIDED MAY NOT BE

COMPATIBLE r i m

ALL

TYPES OF CARRIER BOARDS.

2. INSERT FLAT HEAD SCREWS (nrki A) THROUGH SOLDER SIDE OF

P w o n ' t ( A N N T H E X SPACERS (ITEM B) AND TIGHTEN (4 PLACES)

u m t

HEY SPACER

IS

COMPLETELY

SEATED.

3. CAREFULLY ALIGN P MODULETO CARRIER BOARD MID PRESS

ToCACHER UNTIL CONNECTORS AND SPACERS ARE SEATED.

4. BISON PAN

HEAD

SCREWS (OEM C) THROUGH SOLDER SIDE

OF CARRIER BOARD AND INTO HEX SPACERS (DEM B) AND

11GIDEN (4

PLACES).PLACES).

IP MODULE TO CARRIER BOARD MECHANICAL ASSEMBLY

RI CONNECTOR

2

.3

4

5

MEET:MEAL ASSEMBLY

0

P

I

I 4,1 I : . 4541- 4341131.

A 1 B 1

0

1

6

- 1 3 -