SERIES IP330 INDUSTRIAL I/O PACK 16-BIT HIGH DENSITY ANALOG INPUT MODULE

___________________________________________________________________________________

- 2 -

The information contained in this manual is subject to change

without notice. Acromag, Inc. makes no warranty of any kind with

regard to this material, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose.

Further, Acromag, Inc. assumes no responsibility for any errors

that may appear in this manual and makes no commitment to

update, or keep current, the information contained in this manual.

No part of this manual may be copied or reproduced in any form,

without the prior written consent of Acromag, Inc.

Table of Contents

Page

1.0 GENERAL NFORMATION

............................................ 2

KEY IP330 FEATURES.................................................

2

INDUSTRIAL I/O PACK INTERFACE FEATURES........ 3

SIGNAL INTERFACE PRODUCTS.............................. 3

INDUSTRIAL I/O PACK SOFTWARE LIBRARY........... 4

2.0 PREPARATION FOR USE

............................................ 4

UNPACKING AND INSPECTION..................................

4

CARD CAGE CONSIDERATIONS................................

4

BOARD CONFIGURATION..........................................

4

Default Hardware Jumper Configuration..................

5

Analog Input Range Hardware Jumper Configuration

5

Power Supply Hardware Jumper Configuration.......

5

Software Configuration.............................................

5

CONNECTORS............................................................

5

IP Field I/O Connector (P2).......................................

5

Analog Inputs: Noise and Grounding Considerations.

6

External Trigger Input/Output....................................

6

IP Logic Interface Connector (P1)............................. 6

3.0

PROGRAMMING INFORMATION

................................ 6

IP IDENTIFICATION PROM.........................................

6

I/O SPACE ADDRESS MAPS.......................................

7

Control Register.......................................................

8

Analog I/P Ranges & Corresponding Digital O/P Codes

8

Interrupt Vector Register..........................................

9

Timer Prescaler Register..........................................

9

Conversion Timer Register........................................

9

Start Channel Value Register....................................

9

End Channel Value Register.....................................

9

New Data Register....................................................

10

Missed Data Register................................................

10

Start Convert Register..............................................

10

Gain Select Registers................................................

11

Mail Box Buffer..........................................................

11

MODES OF OPERATION............................................

11

Uniform Continuous-Mode.........................................

11

Uniform Single-Mode.................................................

12

Burst Continuous-Mode............................................

12

Burst Single-Mode....................................................

12

Convert On External Trigger Only Mode....................

12

PROGRAMMING CONSIDERATIONS.........................

13

Use of Calibration Signals.........................................

13

Calibration Programming Example 1........................

14

Calibration Programming Example 2........................

15

Programming Interrupts............................................

17

4.0

THEORY OF OPERATION

........................................... 17

FIELD ANALOG INPUTS.............................................

17

LOGIC/POWER INTERFACE.......................................

18

IP INTERFACE LOGIC.................................................

18

IP330 CONTROL LOGIC..............................................

18

INTERNAL CHANNEL POINTERS...............................

18

EXTERNAL TRIGGER..................................................

19

TIMED PERIODIC TRIGGER CIRCUIT........................ 19

INTERRUPT CONTROL LOGIC................................... 19

5.0

SERVICE AND REPAIR

................................................ 19

SERVICE AND REPAIR ASSISTANCE........................

19

PRELIMINARY SERVICE PROCEDURE..................... 19

6.0

SPECIFICATIONS

......................................................... 20

GENERAL SPECIFICATIONS.......................................

20

ANALOG INPUT...........................................................

20

INDUSTRIAL I/O PACK COMPLIANCE........................ 21

APPENDIX

......................................................................

21

CABLE: MODEL 5025-551............................................

21

Recommended APC8600 Shieled Cable.......................

21

TERMINATION PANEL: MODEL 5025-552.................. 22

TERMINATION PANEL: MODEL 5029-910.................. 22

TRANSITION MODULE: MODEL TRANS-GP...............

22

DRAWINGS Page

4501-434 IP MECHANICAL ASSEMBLY......................

23

4501-590 IP330 JUMPER LOCATION.........................

24

4501-591 ANALOG INPUT CONNECTION.................. 25

4501-592 IP330 BLOCK DIAGRAM..............................

26

4501-463 CABLE 5025-551 (SHIELDED)..................... 27

4501-464 TERMINATION PANEL 5025-552................ 28

4501-465 TRANSITION MODULE TRANS-GP............ 28

IMPORTANT SAFETY CONSIDERATIONS

It is very important for the user to consider the possible adverse

effects of power, wiring, component, sensor, or software failures

in designing any type of control or monitoring system. This is

especially important where economic property loss or human life

is involved. It is important that the user employ satisfactory overall

system design. It is agreed between the Buyer and Acromag, that

this is the Buyer's responsibility.

1.0 GENERAL INFORMATION

The Industrial I/O Pack (IP) Series IP330 module is a precision

16-bit, high density, single size IP, with the capability to monitor 16

differential or 32 single-ended analog input channels. The IP330

utilizes state of the art Surface Mounted Technology (SMT) to

achieve its high channel density. Four units may be mounted on a

carrier board to provide up to 64 differential or 128 single-ended

analog input channels per 6U-VMEbus system slot or ISA bus

(PC/AT) system slot. The IP330 offers a variety of features which

make it an ideal choice for many industrial and scientific

applications as described below.

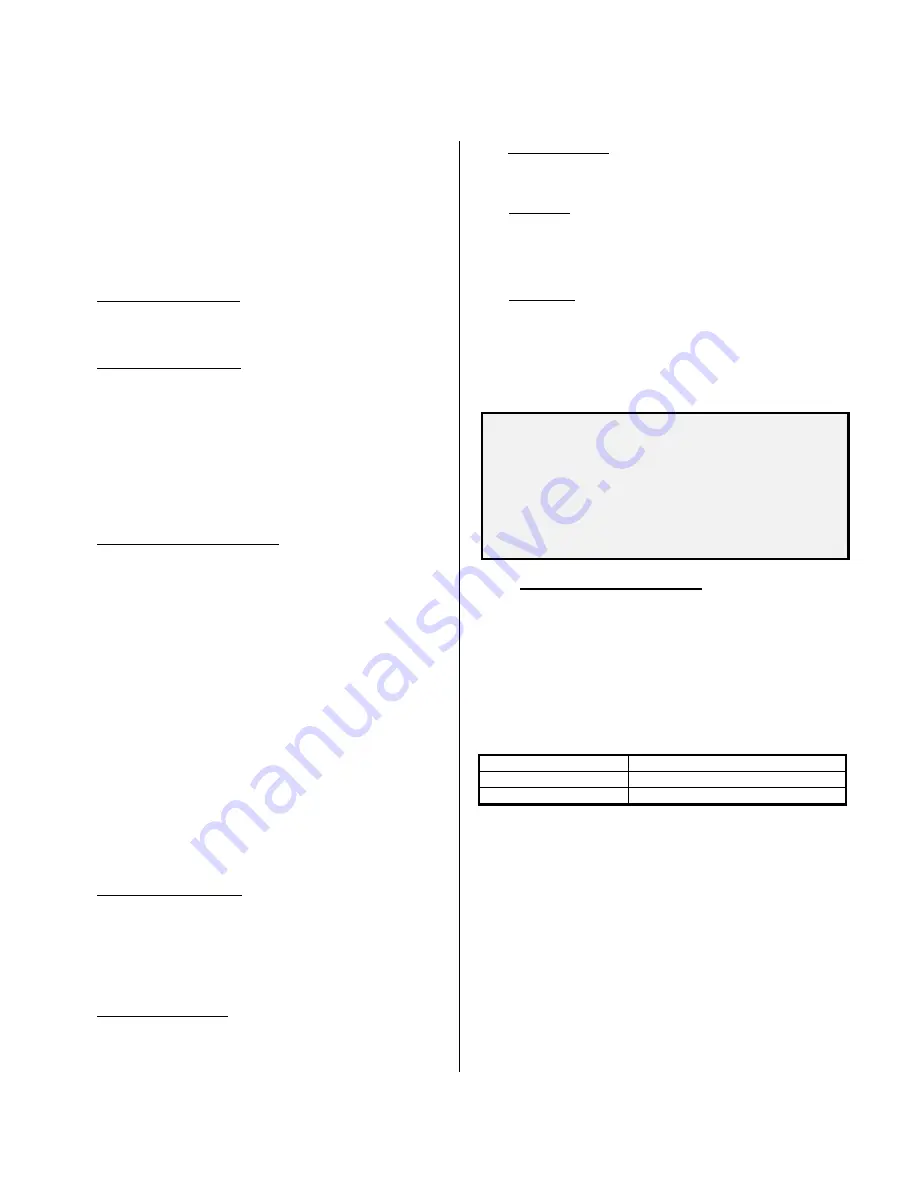

Model

Operating Temperature Range

IP330

0 to 70

°

C

IP330E

-40 to 85

°

C

KEY IP330 FEATURES

•

A/D 16-Bit Resolution

- 16-bit capacitor-based successive

approximation Analog to Digital Converter (ADC) with integral

sample and hold and reference.

•

8

µ

sec Conversion Time

- A maximum conversion rate of

125KHz is supported. Maximum recommended conversion

rate for specified accuracies is 67KHz.

•

High Density

- Monitors up to 16 differential or 32 single-

ended analog inputs (acquisition mode and channels are

selected via programmable control registers).

•

Individual Channel Mail Box -

Two storage buffer registers

are available for each of the 16 differential channels. If

configured for 32 single-ended channels, one storage buffer

register is available for each of the 32 channels.

•

Interrupt Upon Conversion Complete Mode

- May be

programmed to interrupt upon completion of conversion for