SERIES IP400 INDUSTRIAL I/O PACK 40-CHANNEL DIGITAL INPUT MODULE

___________________________________________________________________________________________

-3-

•

Supports 16-bit & 8-bit I/O - Channel register Read/Write is

performed through 16-bit (D16) or 8-bit (D08[EO]) data transfer

cycles in the IP module I/O space.

•

High Speed - Acquisition times for all data transfer cycles are

described in terms of "wait" states - 1 wait state is required for

reading the inputs, 1 wait state for write operations (see

specifications for detailed information).

SIGNAL INTERFACE PRODUCTS

(See Appendix for more information on compatible products)

This IP module will mate directly to any industry standard IP

carrier board (including Acromag AVME9630/9660 3U/6U non-

intelligent carrier boards). Consult the documentation of your carrier

board to ensure compatibility with the following interface products

(since all connections to field signals are made through the carrier

board which passes them to the individual IP modules).

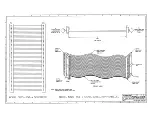

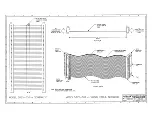

Cables:

Model 5025-551-X (Shielded Cable), or Model 5025-550-X

(Non-Shielded Cable): A Flat 50-pin cable with female

connectors at both ends for connecting AVME9630/9660, or

other compatible carrier boards, to Model 5025-552 termination

panels. The “X” of Model denotes the length in feet. The

unshielded cable is recommended for digital I/O, while the

shielded cable is recommended for optimum performance with

precision analog I/O applications.

Termination Panel:

Model 5025-552: A DIN-rail mountable panel that provides 50

screw terminals for universal field I/O termination. Connects to

Acromag AVME9630/9660, or other compatible carrier boards,

via flat 50-pin ribbon cable (Model 5025-550-X or 5025-551-X).

Transition Module:

Model TRANS-GP: This module repeats field I/O connections

of IP modules A through D for rear exit from the card cage. It is

available for use in card cages which provide rear exit for I/O

connections via transition modules (transition modules can only

be used in card cages specifically designed for them). It is a

double-height (6U), single-slot module, with front panel

hardware adhering to the VMEbus mechanical dimensions,

except for shorter printed circuit board depth. It connects to

Acromag Termination Panel 5025-552 from the rear of the card

cage, and to AVME9630/9660 boards within the card cage, via

flat 50-pin ribbon cable (Model 5025-550-X or 5025-551-X).

INDUSTRIAL I/O PACK SOFTWARE LIBRARY

Acromag provides an Industrial I/O Pack Software Library

diskette (Model IPSW-LIB-M03, MSDOS format) to simplify

communication with the board. All functions are written in the “C”

programming language and can be linked to your application. Refer

to the “README.TXT” file in the root directory and the

“INFO400.TXT” file in the “IP400” subdirectory on the diskette for

more details.

2.0 PREPARATION FOR USE

UNPACKING AND INSPECTION

Upon receipt of this product, inspect the shipping carton for

evidence of mishandling during transit. If the shipping carton is

badly damaged or water stained, request that the carrier's agent be

present when the carton is opened. If the carrier's agent is absent

when the carton is opened and the contents of the carton are

damaged, keep the carton and packing material for the agent's

inspection.

For repairs to a product damaged in shipment, refer to the

Acromag Service Policy to obtain return instructions. It is

suggested that salvageable shipping cartons and packing material

be saved for future use in the event the product must be shipped.

This board is physically protected with

packing material and electrically

protected with an anti-static bag during

shipment. However, it is recommended

that the board be visually inspected for

evidence of mishandling prior to

applying power.

The board utilizes static sensitive

components and should only be

handled at a static-safe workstation.

CARD CAGE

CONSIDERATIONS

Refer to the specifications for loading and power requirements.

Be sure that the system power supplies are able to accommodate

the power requirements of the carrier board, plus the installed IP

modules, within the voltage tolerances specified.

IMPORTANT: Adequate air circulation must be provided to prevent

a temperature rise above the maximum operating temperature.

The dense packing of the IP modules to the carrier board

restricts air flow within the card cage and is cause for concern.

Adequate air circulation must be provided to prevent a temperature

rise above the maximum operating temperature and to prolong the

life of the electronics. If the installation is in an industrial

environment and the board is exposed to environmental air, careful

consideration should be given to air-filtering.

BOARD CONFIGURATION

Power should be removed from the board when installing IP

modules, cables, termination panels, and field wiring. Refer to

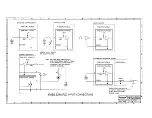

Mechanical Assembly Drawing 4501-434 and your IP module

documentation for configuration and assembly instructions. Model

IP400 Input Boards have no jumpers or switches to configure--

interrupts are configured through software command.

CONNECTORS

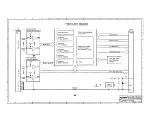

IP Field I/O Connector (P2)

P2 provides the field I/O interface connector for mating IP

modules to the carrier board. P2 is a 50-pin female receptacle

header (AMP 173279-3 or equivalent) which mates to the male

connector of the carrier board (AMP 173280-3 or equivalent). This

provides excellent connection integrity and utilizes gold-plating in the

mating area. Threaded metric M2 screws and spacers are supplied

with the module to provide additional stability for harsh environments

(see Mechanical Assembly Drawing 4501-434). The field and logic

side connectors are keyed to avoid incorrect assembly.