SERIES IP503 INDUSTRIAL I/O PACK EIA/TIA-232E & CENTRONICS COMMUNICATION MODULE

___________________________________________________________________________________________

- 20 -

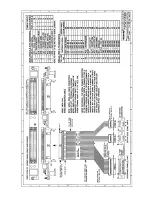

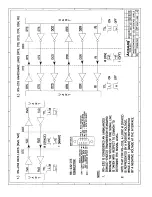

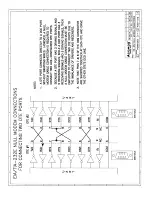

Note that the field interface to the carrier board provided

through connector P2 (refer to Table 21) is NON-ISOLATED.

This means that the field signal return and logic common have a

direct electrical connection to each other. As such, care must be

taken to avoid ground loops (see Section 2 for connection

recommendations) Ignoring this effect may cause operation

errors, and with extreme abuse, possible circuit damage. Refer

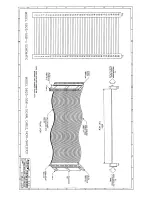

to Drawing 4501-550 for example communication wiring and

grounding connections.

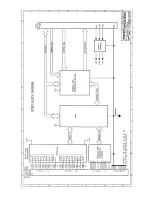

LOGIC/POWER INTERFACE

The logic interface to the carrier board is made through

connector P1 (refer to Table 22)P1 also pr5V and

±

12V

to power the module. Not all of the IP logic P1 pin functions are

used.

A programmable logic device installed on the IP Module

provides the control signals required to operate the board. It

decodes the selected addresses in the I/O and ID spaces and

produces the chip selects, control signals, and timing required by

the communication registers and ID PROM, as well as, the

acknowledgment signal required by the carrier board per the IP

specification also prioritizes the interrupts coming in from the

ports.

The ID PROM (read only) implemented on the IP module

provides the identification for the individual module per the IP

specification. The ID PROM, configuration control registers, and

FIFO buffers are all accessed through an 8-bit data bus interface

to the carrier board

5.0 SERVICE AND REPAIR

SERVICE AND REPAIR ASSISTANCE

Surface-Mounted Technology (SMT) boards are generally

difficult to repair. It is highly recommended that a non-functioning

board be returned to Acromag for repair. The board can be easily

damaged unless special SMT repair and service tools are used.

Further, Acromag has automated test equipment that thoroughly

checks the performance of each board. When a board is first

produced and when any repair is made, it is tested, placed in a

burn-in room at elevated temperature, and retested before

shipment

Please refer to Acromag's Service Policy Bulletin or contact

Acromag for complete details on how to obtain parts and repair

PRELIMINARY SERVICE PROCEDURE

Before beginning repair, be sure that all of the procedures in

Section 2, Preparation For Use, have been followed. Also, refer

to the documentation of your carrier board to verify that it is

correctly configured. Replacement of the module with one that is

known to work correctly is a good technique to isolate a faulty

module

CAUTION:POWER MUST BE TURNED OFF BEFORE

REMOVING OR INSERTING BOARDS

Acromag’s Application Engineers can provide further

technical assistance if required. When needed, complete repair

services are also available from Acromag.

6.0SPECIFICATIONS

GENERAL SPECIFICATIONS

UART Texas Instruments............... TL16C552AFN

Operating Temperature.................. 0 to +70

°

C

Relative Humidity ........................... 5-95% non-condensing

Storage Temperature ..................... -55

°

C to +125

°

C

Physical Configuration ................... Single Industrial I/O Pack

Module

Length............................................ 3880 inches (985 mm)

Width ............................................. 1780 inches (452 mm)

Board Thickness ............................ 0062 inches (159 mm)

Max Component Height.................. 0314 inches (797 mm)

Connectors:

P1 (IP Logic Interface).......... 50-pin female receptacle

header (AMP 173279-3

or equivalent)

P2 (Field I/O) ........................ 50-pin female receptacle

header (AMP 173279-3

or equivalent)

Power:

+5 Volts (

±

5%)...................... 200mA Typical, 300mA

Maximum

+12 Volts (

±

5%) from P1 ...... 30mA Typical, 42mA

Maximum (No load)

-12 Volts (

±

5%) from P1 ....... 30mA Typical, 42mA

Maximum (No load)

Non-Isolated .................................. Logic and field commons

have a direct electrical

connection

Resistance to RFI .......................... No data upsets occur for field

strengths up to 10V per meter

at 27MHz, 151MHz, &

460MHz per SAMA PMC 331

test procedures

Resistance to EMI.......................... Unit has been tested with no

data upsets under the

influence of EMI from

switching solenoids,

commutator motors, and drill

motors

ESD Protection .............................. EIA/TIA-232E lines are

protected from ESD voltages

to

±

2KV

EIA/TIA-232E PORTS

Configuration.................................. Two independent, non-

isolated, EIA/TIA-232E serial

ports with a common signal

return connection and

configured as a DTE device

Data Rate....................................... Programmable up to 128K

bits per second using internal

baud rate generator for rated

performance Data rates of

256Kbps and 512Kbps may

be programmed and

communication is possible for

some conditions at these

rates, but performance is

limited and not guaranteed at

these rates Interface.

Asynchronous serial only

Maximum Cable Length ................. 15M (50 feet) typical, limited

to a cable capacitive load of

2500pF

Character Size ............................... Software programmable 5 to

8 bits

Parity ............................................. Software Programmable odd,

even, or no parity

Stop Bits ........................................ Software programmable 1, 1-

1/2, or 2 bits