7

Eubank Wall Mount Heat Pump I&O Manual

05/2023 Rev.2

Model

Weight

Base

w/Economizer

w/3 Phase

w/Economizer & 3 Phase

EAA1020H/EAA1024H/EAA2024H

Lbs (Kg)

337 (153)

357 (162)

356 (161)

376 (171)

EAA1030H/EAA1036H/EAA2030H/EAA2036H

Lbs (Kg)

397 (180)

419 (190)

416 (189)

438 (199)

EAA1042H/EAA1048H/EAA2042H/EAA2048H

Lbs (Kg)

453 (205)

476 (216)

491 (223)

514 (233)

EAA1060H/EAA2060H

Lbs (Kg)

469 (213)

492 (223)

522 (237)

545 (247)

EGA1072H

Lbs (Kg)

576 (261)

599 (272)

629 (285)

652 (296

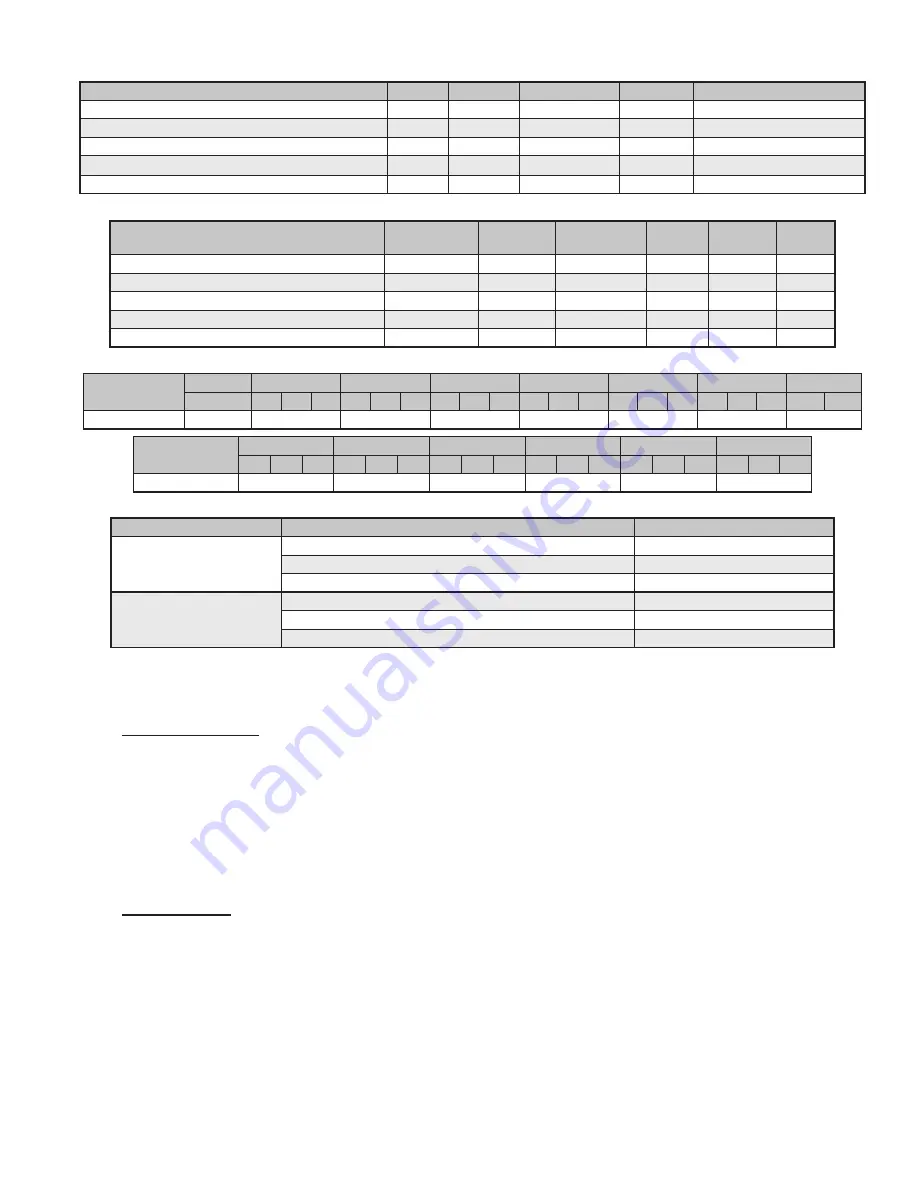

Table 2. Installed Weight (lbs (Kg)

Model

FILTER TYPE

INCHES

MILLIMETERS

PART

NUMBER

FILTERS

PER UNIT

MERV

RATING

EAA1020H/EAA1024H/EAA2024H

Return Air Filter 30 x 16 x 2 762 x 406 x 51

80138

1

8

EAA1030H/EAA1036H/EAA2030H/EAA2036H

Return Air Filter 36½ x 22 x 2 927 x 559 x 51

80162

1

8

EAA1042H/EAA1048H/EAA2042H/EAA2048H

Return Air Filter 36½ x 22 x 2 927 x 559 x 51

80162

1

8

EAA1060H/EAA2060H

Return Air Filter 18 x 24 x 1

457 x 610 x 25

81199

2

8

EGA1072H

Return Air Filter 18 x 24 x 2

457 x 610 x 51

81257

2

8

Table 3. Filter Size (inches)

Model

EAA1020H

EAA1024H

EAA1030H

EAA1036H

EAA1042H

EAA1048H

EAA1060H

EGA1072H

A

A

C

D

A

C

D

A

C

D

A

C

D

A

C

D

A

C

D

C

D

Charge Amount

100

110

114

130

185

185

185

210

Model

EAA2024H

EAA2030H

EAA2036H

EAA2042H

EAA2048H

EAA2060H

A

C

D

A

C

D

A

C

D

A

C

D

A

C

D

A

C

D

Charge Amount

120

120

150

185

185

220

Table 4. Refrigerant Charge (R410A, Ounces)

Basic Model

Special Option

TEMPERATURE RANGES

Non-Economizer

Base Unit

*20ºF - 131ºF (-7ºC - 55ºC)

Desert Duty

*20ºF - 131ºF (-7ºC - 55ºC)

Extreme Duty

*0ºF - 131ºF (-18ºC - 55ºC)

Economizer-Equipped

Base Unit

-40ºF - 131ºF (-29ºC - 55ºC)

Desert Duty

-40ºF - 131ºF (-29ºC - 55ºC)

Extreme Duty

-40ºF - 131ºF (-29ºC - 55ºC)

**An Optional FCC switch is required for the cooling Mode. Heating mode ratings are @47°F Outdoor Temperature. Performance loss

realized below this rating point.

Table 5. Ambient Temperature Operating Ranges

1.5 General Operation

Refrigerant Cycle

Eubank heat pumps use R-410A refrigerant in a conventional vapor-compression refrigeration cycle to

transfer heat. In the cooling mode, a double blower assembly blows indoor air across the evaporator (indoor

coil). Liquid refrigerant passing through the evaporator is boiled into gas by heat removed from the air.

The warmed refrigerant gas enters the compressor where its temperature and pressure are increased. The

hot refrigerant gas condenses to liquid as heat is transferred to outdoor air blown across the condenser

(outdoor coil) by the condenser fan. Liquid refrigerant is metered into the evaporator through a metering

device to repeat the cycle. In the heating mode, the process is reversed.

Heating Mode

During heating mode a special reversing valve reverses the flow of refrigerant through the system

exchanging the roles of the condenser and evaporator. Now the outdoor coil becomes the evaporator and

the indoor coil becomes the condenser. The refrigerant then flows through the outdoor coil, picks up heat

and becomes vaporized. The vapor then enters the compressor where it is compressed to a higher pressure

and temperature. Next it is pumped to the indoor coil where the heat will be released into the room. The

compressed refrigerant vapor will condense to its liquid state as it gives up heat. Finally, liquid flows

through a metering device into the evaporator where the cycle will be repeated.

Optional electric strip heat is available for all models. Please see Appendix A for instructions on field

installation of electric heat.