Suburban Dynaline 3 A&E Manual 12/2021 Rev.2

6

DYNALINE

™

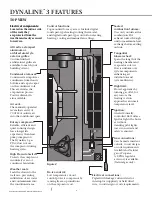

3 FEATURES

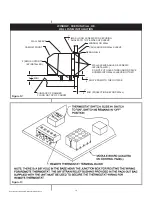

TOP VIEW

De-ice control:

Low temperature cut-out

control protects compressor by

sensing freeze-up conditions

on the evaporator coil.

Electrical components:

Located on the indoor side

of the wall, they

are protected from the

weather and easily accessed

for service.

Attractive stamped

aluminum or

architectural-style

exterior grilles:

Custom finished

architectural grilles are

available to match your

building’s decor.

Condensate removal:

Condenser fan vaporizes

condensate from chassis

bottom and expels vapor

on the condenser coil.

This accelerates the

evaporation process.

Positive drain kit is

also available.

Air vent:

The manually-operated

lever allows entry of

70 CFM of outside air

into the conditioned space.

Rotary compressor:

Reliable, efficient and

quiet-running design

has a longer life

expectancy than heat

pump compressors.

The Dynaline

™

3 gas

PTAC does not use

the compressor during

heating cycles.

High Pressure Switch:

Protects the compressor

in unlikely event of

condenser fan failure.

Weather seals:

Seals the chassis to the

wall case, preventing

infiltration of air, water

and contaminants into

the conditioned area.

Electrical components:

Located on the indoor side

of the wall, they

are protected from the

weather and easily accessed

for service.

Sealed

combustion furnace:

Uses only outside air for

combustion. Hot

exhaust routes through

unit for maximum heat

exchange before exiting

outside.

Tangential

blower wheel:

Spans the length of the

heating chamber and

evaporator coil. Air

flow is uniform over

system components,

enhancing air

distribution and

system efficiency.

High limit:

Protect appliance by

turning gas off if, for

any reason, the

heating section

approaches an unsafe

temperature level.

Ignition:

An electronically

controlled Hot Surface

Ignitor, lights the burn-

er without

standing pilot lights.

Gas is conserved and

safety is ensured.

Gas connections:

Can be made inside or

outside, to suit design

or code requirements.

Available for Natural

gas or Propane.

A 2-PSIG regulator

accessory is available

(Natural gas only).

Control functions:

Top mounted for easy access. Include digital

touch pad-type heating/cooling thermostat,

and digital touch pad-type control for selecting

heating, cooling and manual fan settings.

Figure 2

Electrical connections:

Pigtail with leakage current detector

interruptor (supplied), or field direct

wire, to suit design or code requirements.