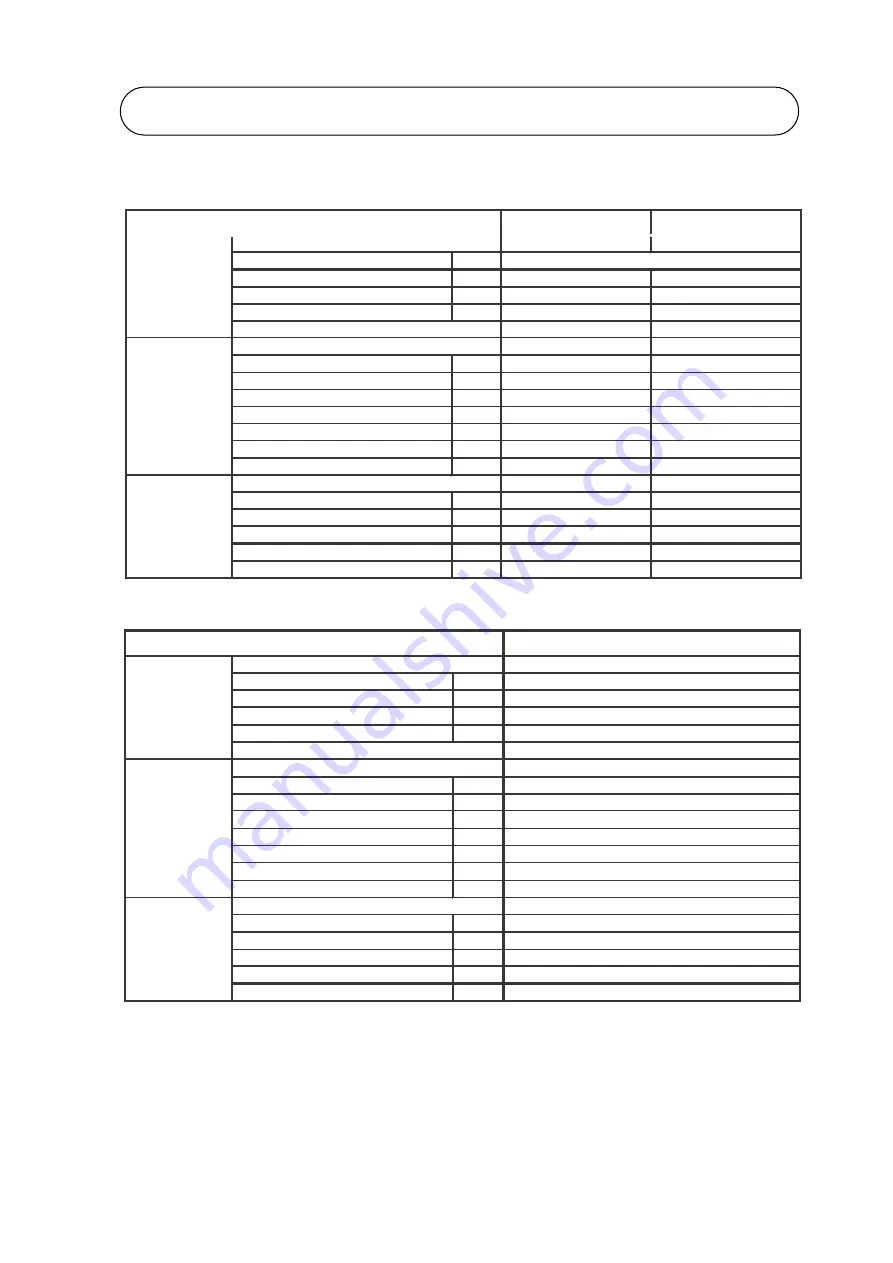

9. ELECTRICAL DATA

ELECTRICAL DATA - HEAT PUMP R410A INVERTER

A5ACV 75CR

B

POWER SOURCE

V/Ph/Hz

220 - 240 / 1 / 50

RATED INPUT POWER

W

300 x2

RATED RUNNING CURRENT

A

1.5 x2

MOTOR OUTPUT

W

145 x2

8

E

POWER SOURCE

V/Ph/Hz

380 - 415 / 3 / 50

CAPACITOR

m

F

NA

RATED INPUT POWER (COOLING)

W

7700

RATED INPUT POWER (HEATING)

W

6500

RATED RUNNING CURRENT (COOLING)

A

14.3

RATED RUNNING CURRENT (HEATING)

A

13.1

LOCKED ROTOR AMP.

A

NA

F

POWER SOURCE

V/Ph/Hz

380 - 415 / 3 / 50

RATED INPUT POWER (COOLING)

W

750

RATED INPUT POWER (HEATING)

W

800

RATED RUNNING CURRENT (COOLING)

A

1.3

RATED RUNNING CURRENT (HEATING)

A

1.4

MODEL

INSULATION GRADE

INSULATION GRADE

CONDENSER FAN

MOTOR

POLES

INSULATION GRADE

COMPRESSOR

WATER PUMP

A5ACV 30CR

A5ACV 55CR

F

F

POWER SOURCE

V/Ph/Hz

RATED INPUT POWER

W

135

270

RATED RUNNING CURRENT

A

0.6

1.3

MOTOR OUTPUT

W

-

-

6

6

E

F

POWER SOURCE

V/Ph/Hz

220 - 240 / 1 / 50

380 - 415 / 3 / 50

CAPACITOR

m

F

NA

NA

RATED INPUT POWER (COOLING)

W

4945

6630

RATED INPUT POWER (HEATING)

W

4077

5130

RATED RUNNING CURRENT (COOLING)

A

18.3

13.5

RATED RUNNING CURRENT (HEATING)

A

15.7

11.4

LOCKED ROTOR AMP.

A

NA

NA

F

F

POWER SOURCE

V/Ph/Hz

220 - 240 / 1 / 50

380 - 415 / 3 / 50

RATED INPUT POWER (COOLING)

W

199

700

RATED INPUT POWER (HEATING)

W

206

700

RATED RUNNING CURRENT (COOLING)

A

0.9

1.3

RATED RUNNING CURRENT (HEATING)

A

0.9

1.3

220 - 240 / 1 / 50

POLES

INSULATION GRADE

COMPRESSOR

WATER PUMP

MODEL

INSULATION GRADE

INSULATION GRADE

CONDENSER FAN

MOTOR

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

73

Summary of Contents for A5ACV 100 CR

Page 43: ...INSTALLATION A5ACV 30 55 75CR 41 ...

Page 44: ...A5ACV 30CR A5ACV 55CR 75CR 42 ...

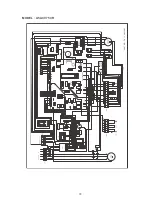

Page 78: ...10 WIRING DIAGRAMS PA R T NO 50 13 9 026086 MODEL A5ACV 30CR 76 ...

Page 79: ...77 MODEL A5ACV 55CR ...

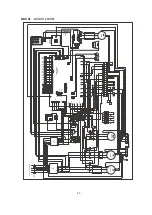

Page 80: ...MODEL A5ACV 75CR PA R T NO 50 13 4 083602 78 ...

Page 81: ...MODEL A5ACV 100 135CR 79 ...