14

ACT Dust Collectors

Bag-In Bag-Out Collars (OPTIONAL)

Bag-in/bag-out collars are used when harmful dusts are present or simply to minimize exposure to any dust.

They minimize the amount of dust the operator comes in contact with by allowing the operator to replace the

filters by using a bag strapped onto the collar. Although this procedure does greatly reduce exposure to the

dusts, it is hard to completely avoid any exposure. It is strongly recommended that the operator still use

proper protective clothing, including respirators.

1. Remove the filter access cover and set it aside.

If you would like, you can use a bag for this

process to further minimize exposure. Starting

at the top row of the dust collector will prevent

dusts from falling on to new filters already

installed in the rows below.

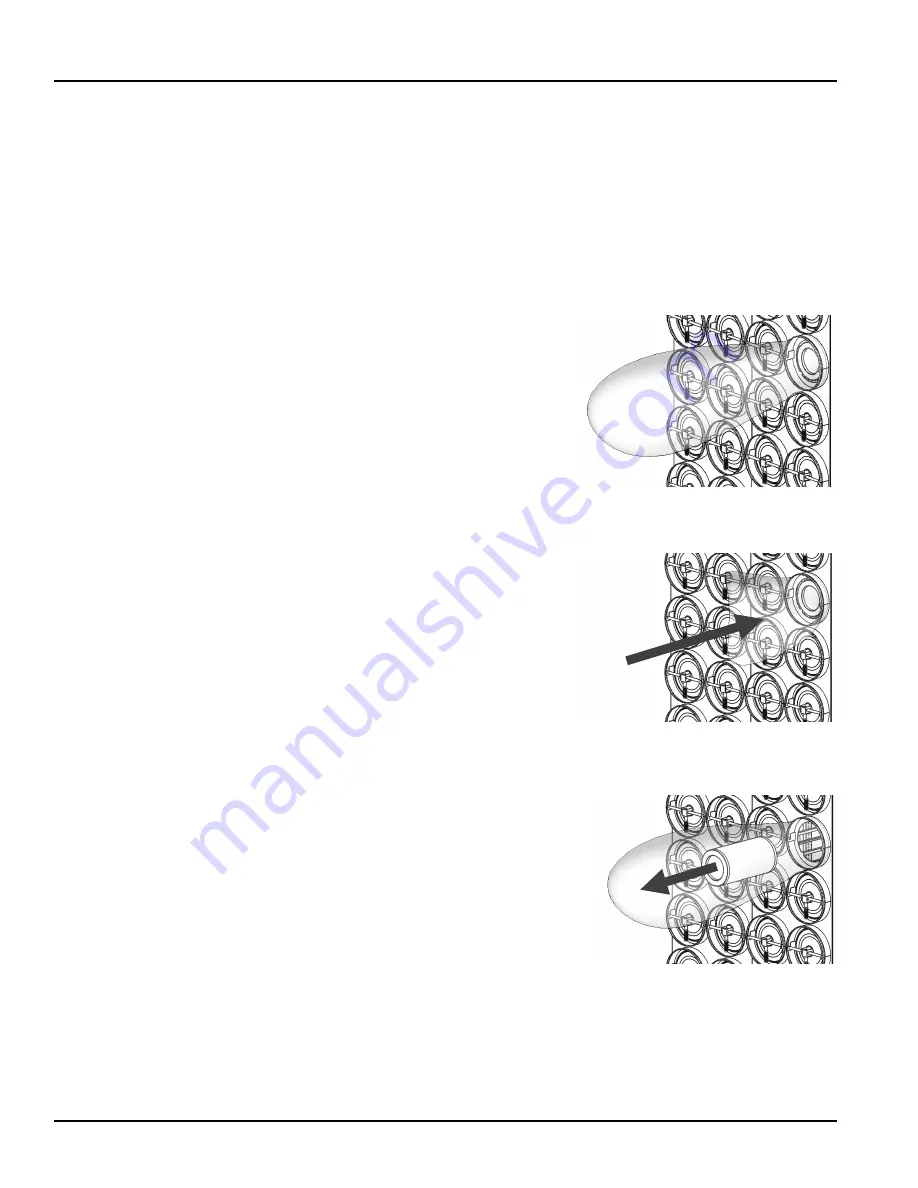

2. Take a new bag and place it over the outside of

the bag collar. Secure the bag around the collar

with the provided strap. Securely tighten the

strap.

3. Grab the bottom of the bag, reach in and twist

the filter to drop off any dust that may be in the

pleats of the filter, and then pull the filter out into

the bag.

4. Before removing the bag from the collar, it is

recommended that you twist the bag to prevent

the dust from escaping and use a tie to seal off

the bag.

5. Remove the bag from the collar.

6. If there are two filters in your filter access hole,

repeat this process for the next filter.

7. Place the new filter into the filter access hole. To

further minimize exposure to dusts, this can be

done by first loading the new filter into a bag.

8. Replace the filter access door and continue this

process until all filters have been replaced.

Secure bag on to the collar

Reach in and grab the filter with the bag

Remove the filter while still inside of the bag