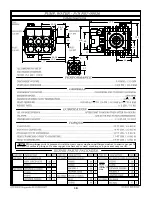

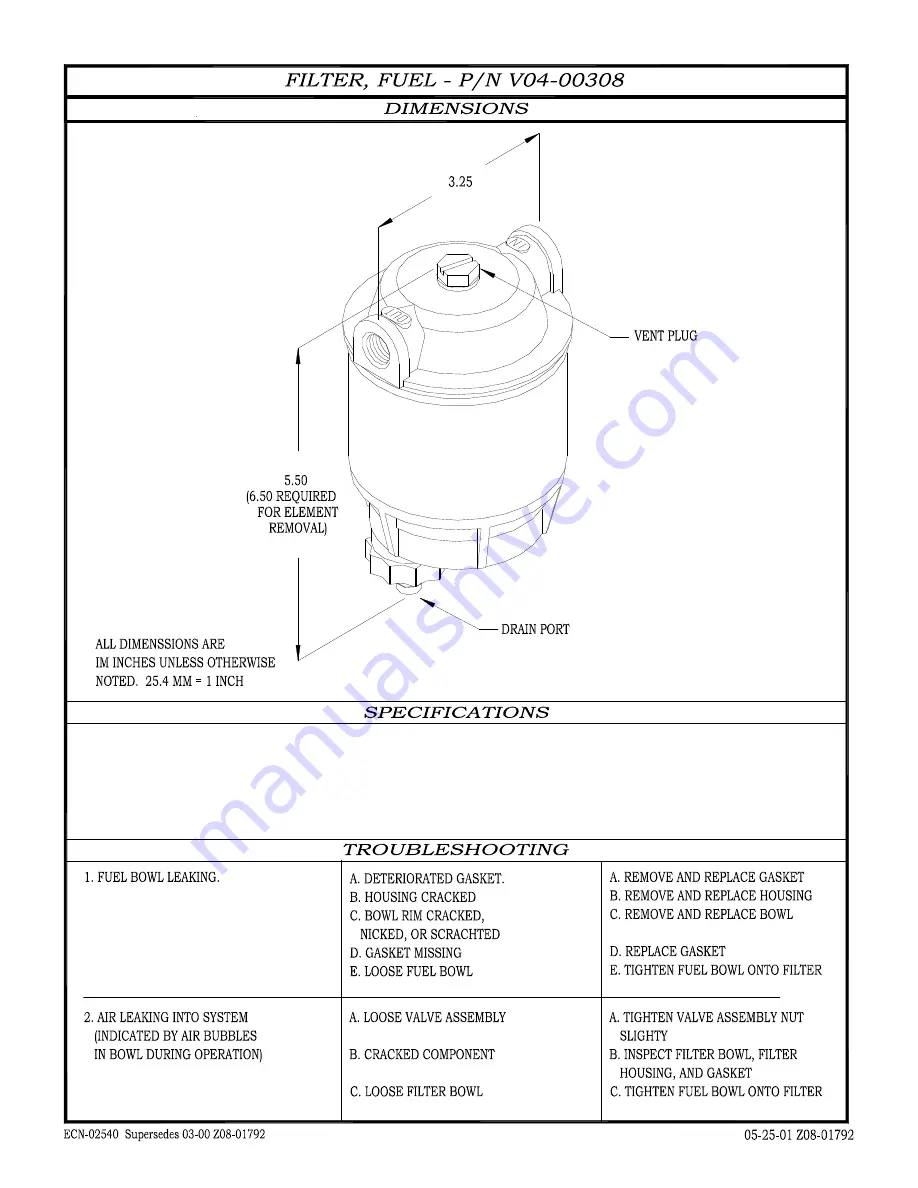

MAXIMUM FLOW................................................................................................15 GPH / 57 LPM

MAXIMUM FILTRATION................................................................................................2 MICRONS

MAXIMUM TEMPERATURE..........................................................................................212° / 100°

WEIGHT.................................................................................................................1 LB / 340 GM

INLET AND OUTLET PORT SIZE........................................................................................1/4 NPT

9

Summary of Contents for 246-200D0

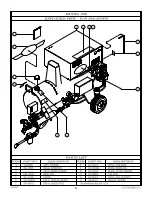

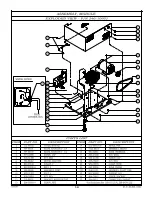

Page 23: ...2 2 ...

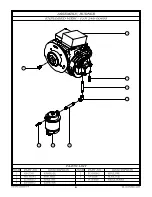

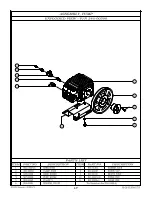

Page 24: ...3 ...

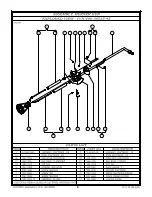

Page 25: ...12 05 03 Z08 11218 ECN 02981 Supersedes 07 31 03 Z08 11218 4 ...

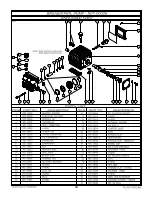

Page 26: ...5 12 05 31 Z08 11218 ECN 02810 Supersedes 07 31 03 ...

Page 27: ...6 ...

Page 28: ...7 ...

Page 29: ...8 ...

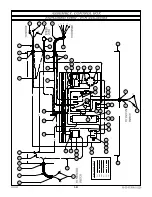

Page 33: ...WIRE COLOR CODE 12 ...

Page 34: ...13 ...

Page 35: ...14 ...

Page 36: ...15 ...

Page 37: ...16 ...

Page 38: ...17 ...

Page 40: ...19 ...

Page 44: ...23 ...