7

20210408 - LNNN00354 (3.0) Swegon reserves the right to alter specifications.

Actionair DWFX-F Installation Guide

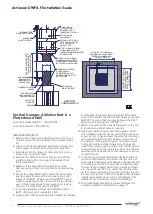

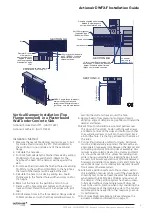

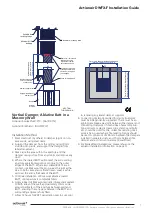

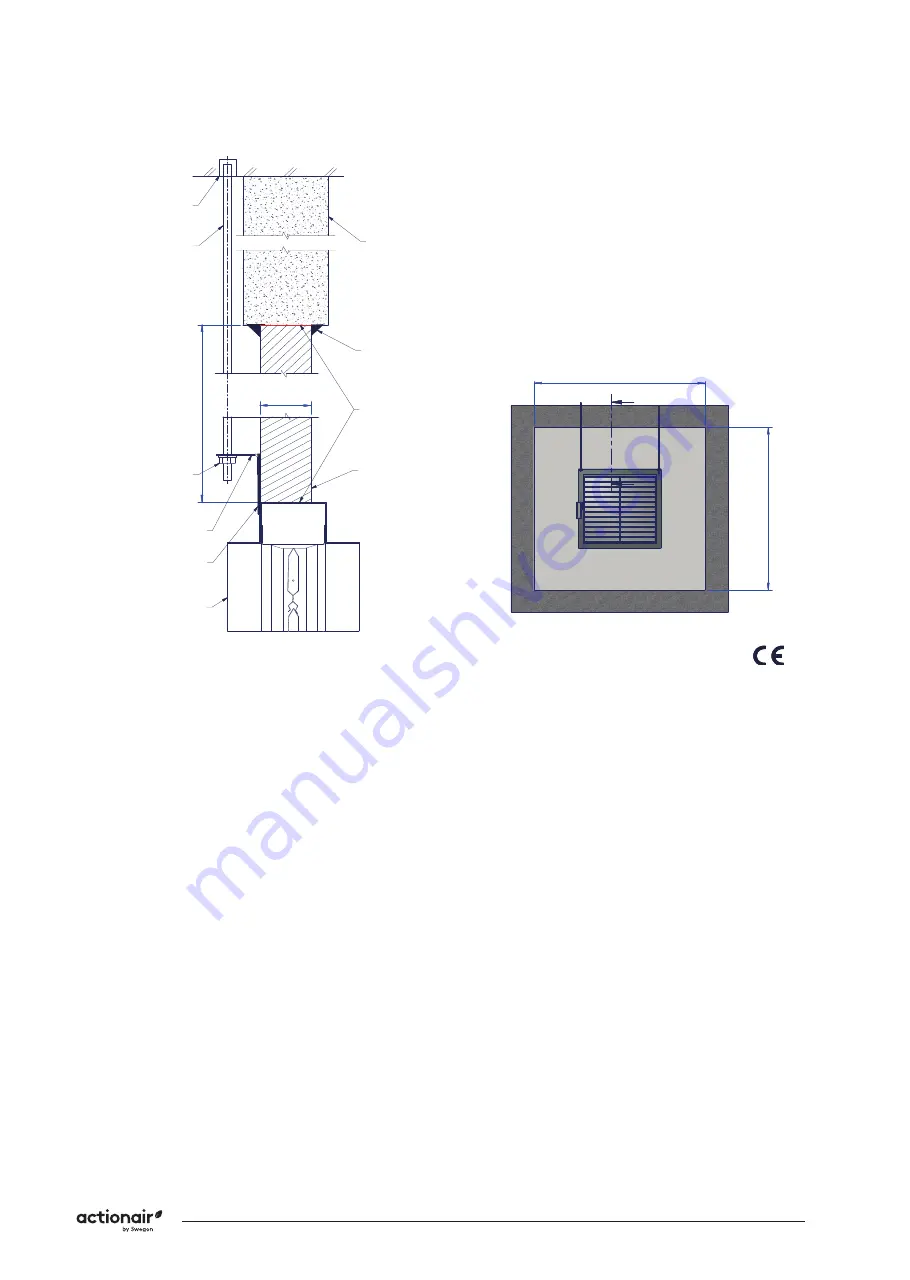

Vertical Damper, Ablative Batt in a

Masonry Wall

Actionair SmokeShield PTC - [AA/F10712]

Actionair FireShield - [AA/F10713]

Installation Method

1.

Rivet steel duct (by others) to damper spigot on non-

access side, using steel rivets.

2. Suspend the damper from the ceiling, using 10mm

studding drop rods, and support the damper from

lateral movement.

3. Make sure the area within the aperture and the

damper casing is free from any debris and remove any

dust.

4. Where the coated BATT will contact the surrounding

aperture apply Rockwool Fire pro glue to the outer

edges of the BATT. Where two coated BATTS are in

contact, use Rockwool fire pro glue as the joint adhe

-

sive. In both cases ensure that an even cover is achie-

ved over the entire thickness of the BATT.

5.

Continue installation of Rockwool ablative coated

BATT, until aperture is completely filled.

6.

Apply a bead of Rockwool acoustic intumescent sealant

to both sides of the wall, approximately 15mm wide

around perimeter of the aperture between wall and

BATT, ensuring that any gaps between the BATT and

surrounding edges are fully filled.

7.

Allow 12 hours for BATT penetration seal to cure prior

Comments:

Rev:

Drawn By:

S.Wehrle

Approved By:

A. Hill

1 of 1

Reference No:

S. Gore

Date:

Date:

By:

Date:

25/11/2019

15/07/2010

25/11/2019

Date:

H

Checked By:

Sheet

Rev

AAF10712

Description:

If your proposed installation details differ from

that shown here, please discuss this with the

Building Control Authority (BCA), referencing

this documentation, associated fire tests,

assessments, and other documentation shown

below. Deviation from this drawing requires

the approval of the relevant authority.

Installation Detail

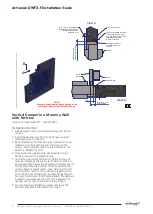

Connecting ductwork omitted for clarity.

Ductwork must be independently supported.

There must be an appropriate break-away joint

between the damper and connecting ductwork

on both sides of assembly. Aluminium rivets or

plastic cleats, clips, clamps and bolts etc.

should be used for this, unless fire resisting

ductwork is being used where fire resisting

fixings should be used. A minimum of 200 mm

between fire dampers installed in separate

ducts and 75 mm between fire damper and a

construction element (wall/floor).

IF YOUR PROPOSED

INSTALLATION DETAIL DIFFERS

FROM THAT SHOWN, YOU MUST

DISCUSS THIS WITH THE

BUILDING CONTROL AUTHORITY

(BCA), REFERENCING THIS

DOCUMENT AND THE

ASSOCIATED FIRE TESTS,

ASSESSMENTS AND OTHER

DOCUMENTS SHOWN BELOW.

DEVIATION FROM THIS DRAWING

REQUIRES THE APPROVAL OF

THE RELEVANT AUTHORITY.

© Swegon Air Management Limited

South Street, Whitstable, Kent CT5 3DU

Tel: +44 (0)1227 276100

Fax: +44 (0)1227 264262

www.swegonair.co.uk

Applicable Test Report to

BS EN1366-2:

APPLUS 19/20747-1925

MINUTES

ES120

Fire Resistance

Integrity and Leakage

E

EC1770

MJB 20-02-18

Damper Size Range (mm)

VERTICAL APPLICATION

SMOKE DWFX-F &

ABLATIVE BATT

200 x 200 to 1000 x 1000

VERTICAL BLADES;

Damper can be installed with the blades in the

vertical orientation with actuator mounted at

either the top or bottom. For cleat locations of

motors mounted on top refer to drawing

F

EC1830

RTC 20/03/18

G

EC1839

RTC 13/04/18

CHANGE IN PROGRESS

See Mark Bushell

H

ECN1959

MJB 26-11-19

to removing any lateral damper supports.

8. Connecting ductwork omitted for clarity. Ductwork

must be independently supported. There must be an

appropriate break-away joint between the damper and

connecting ductwork on both sides of assembly. Alu-

minium rivets or plastic cleats, clips, clamps and bolts

etc. should be used for this, unless fire resisting duct-

work is being used where fire resisting fixings should

be used. A minimum of 200 mm between fire dampers

installed in separate ducts and 75 mm between fire

damper and a construction element (wall/floor).

9.

For SmokeShield installations, please reference the

actuator installation information on page 11.