4

5

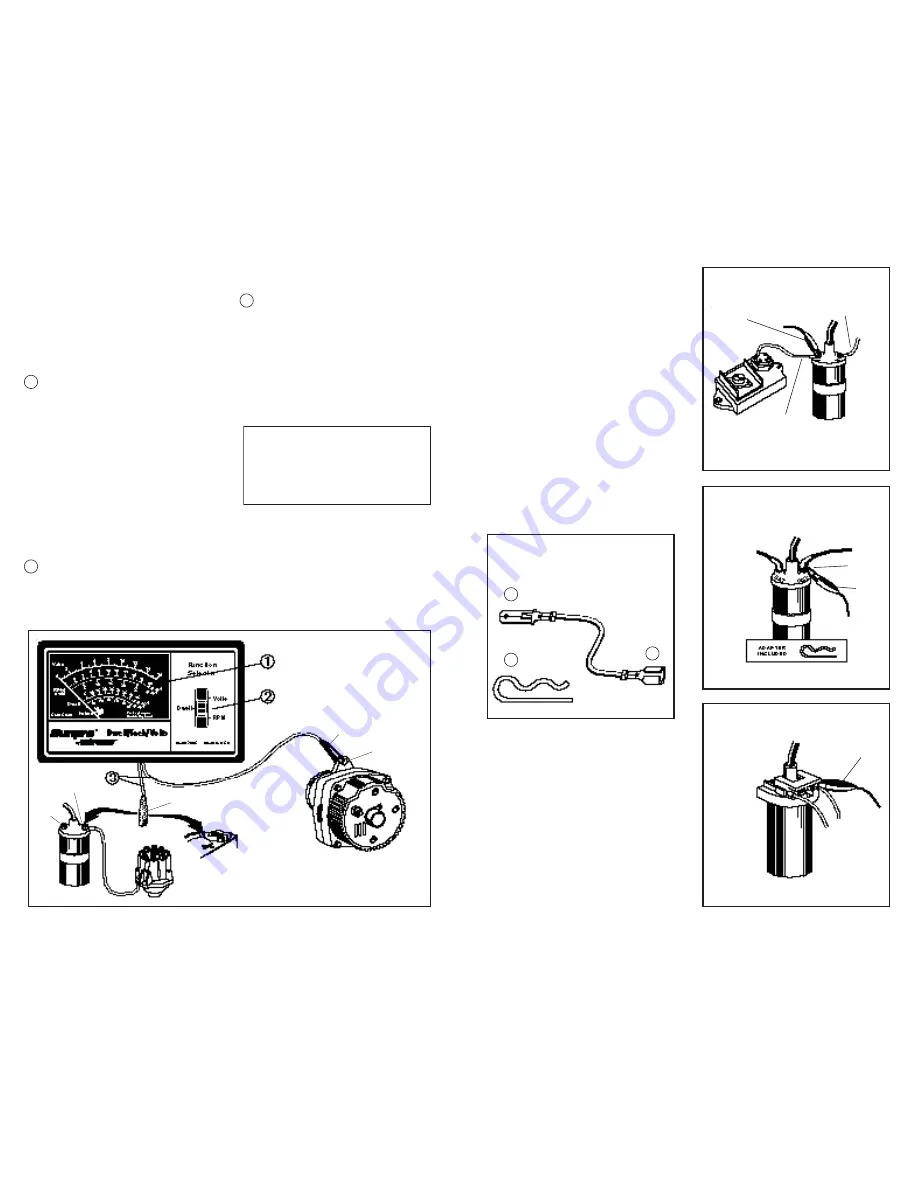

FUNCTIONS, CONNECTIONS AND ACCESSORIES

DESCRIPTION

The Model CP7605 Dwell/Tach/Voltmeter has a

clearly labeled function switch and meter as shown

in the Master Hookup diagram, Figure 1 below.

1. METER

This meter displays the following scales:

• Volts

0-16

• RPM

0-2000 (8 cylinder)

0-4000 (4 cylinder

– multiply

8 cylinder scale

by 2)

• RPM

0-2500 (6 cylinder)

• Dwell

0-45 degrees (8 cylinder)

0-90 degrees (4

cylinder–

multiply 8 cylinder by 2)

• Dwell 0-60 degrees (6 cylinder)

•

Points OK/Defective

2. FUNCTION

SELECTOR

This selects the RPM, Dwell, or Volts functions

of the instrument.

3. TEST

LEAD

Hook this lead to the proper test point in the

vehicle to perform tests as required and as

described below:

VOLTAGE

MEASUREMENTS

GREEN CLIP – Connect to the Positive (+) volt-

age source to be measured. (+ Battery terminal,

alternator output terminal, lamp socket, etc.).

BLACK CLIP – Vehicle ground.

CAUTION!

Avoid connecting the BLACK CLIP to the

negative(-) battery terminal or any fuel sys-

tem components in the event that glasses are

present which could explode from sparking

connections.

DWELL/TACH/BREAKER

POINT

RESISTANCE

MEASUREMENT

GREEN CLIP – Connect to the Tach or negative

(-) ignition coil terminal. See Figures 3 through

10 for specifi c applications

BLACK CLIP – Vehicle Ground. See CAUTION

under voltage measurements.

Fig. 1

Master Hookup Diagram

DISTRIBUTOR

DIST. OR

TACH

BAT.

GREEN

ENGINE

GROUND

BLACK

ACCESSORIES

See Figure 2.

1. GM DIAGNOSTIC ADAPTOR

The GM Diagnostic Adaptor is used to make

connection to vehicle equipped with the GM Di-

agnostic Connector, (1976 –1982). It is also used

to make connection to Toyota vehicles which

use the IIA (Integrated Ignition Assembly). See

Figures 9 and 10 for adaptor application.

2. GM HEI ADAPTOR

The GM HEI Adaptor is used to provide connec-

tion to the “TACH” terminal on GM HEI systems.

See Figure 7 for typical installation.

3. FORD COIL CLIP

The Ford Coil Clip is used for ignition systems

which have booted ignition coil connections.

See Figure 4 for clip application.

ELECTRICAL SYSTEM TESTS –

"VOLTS" POSITION

Fig. 2

Accessories

3

2

1

Fig. 3

Primary Tach Connection —

GREEN

Clip

Fig. 4

Primary Tach/Dwell Connection –

GREEN

Clip

Fig. 5

Primary Tach Connection —

GREEN

Clip

COIL

(BAT.)

GREEN

CLIP

TO BAL-

LAST

TO IGNITION

SWITCH

FORD

ADAPTER

TO DIST.

GREEN

CLIP

CONTROL

UNIT

TO CONTROL

UNIT

1974 Ford Electronic and All Breaker

Points Ignition Systems

All Chrysler Corporation Electronic Igni-

tions, 6 & 8 cylinder shown

1972 - 1986

GREEN

CLIP

Ford Solid State & Dura Spark systems

1975 - 1986

COIL