6

7

GREEN

CLIP

GREEN

CLIP

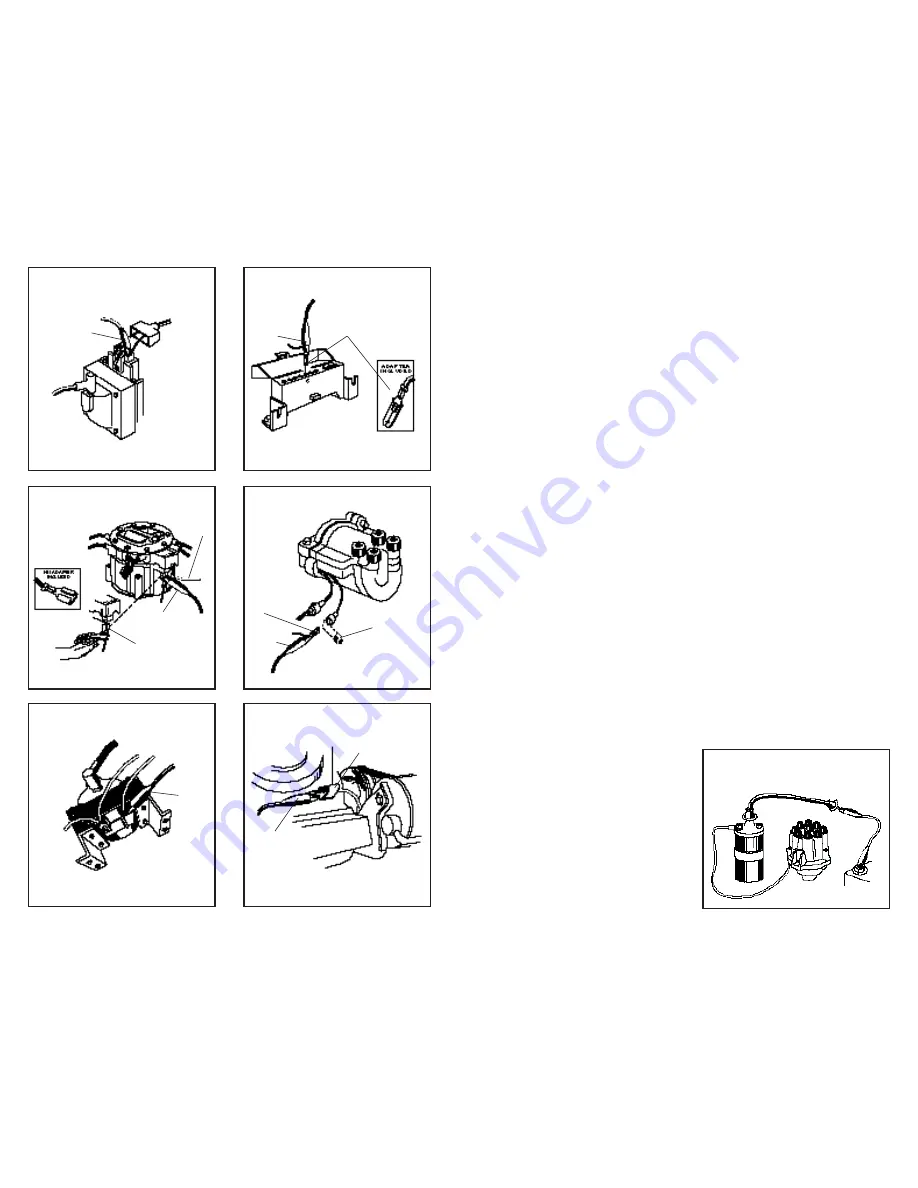

Fig. 8

Primary Tach Connection —

GREEN

Clip

Fig. 7

Primary Tach Connection —

GREEN

Clip

Fig. 6

Primary Tach Connection —

GREEN

Clip

Ford TFI Systems 1981 - 1986

Delco HEI 1974 - 1986 External Coil

INSERT

DIAGNOSTIC

ADAPTER

Fig. 9

Primary Tach Connection —

GREEN

Clip

Fig. 10

Primary Tach Connection —

GREEN Clip

GM Diagnostic Connector and

Delco HEI Systems 1976 - 1982

Toyota IIA (Integrated Ignition As-

sembly) 1983 - 1986

GREEN

CLIP

SPADE

TERMINAL

ADAPTER

GREEN

CLIP

REMOVE CAP

FROM TACH

TEST CONNEC-

TOR

GREEN

CLIP

ADAPTER

TO

IGNITION

SWITCH

Delco HEI 1974 - 1986 Integral Coil

Fig. 11

Performance Check ONLY

Note: This is NOT a Tach Connection point.

GM C3 (Computer Command Control)

GREEN CLIP or

Ground Jumper

– See Vehicle

Service Manual

DWELL CONNEC-

TOR (GREEN)

BASIC SYSTEM CHECK – Charging Voltage

1. GREEN CLIP – Connect to the Positive (+) Battery

terminal.

2. BLACK CLIP – Connect to Vehicle Ground.

3. FUNCTION SELECTOR – Volts

4. Start engine and allow it to warm up completely.

Operate it at curb idle.

5. With all accessories off observe the 16 volt scale

on the analyzer.

6. Normal Result – 13.2 to 15.2 volts or as specifi ed

in the vehicle service manual.

7. FUNCTION SELECTOR – RPM

8. Select a step on the fast idle cam which will

maintain engine speed between l800 and 2000

RPM (or have an assistant hold engine speed

in this range) through Step 12.

9. FUNCTION

SELECTOR

–

Volts

10. Observe the 16 volt scale on the analyzer. The

voltage should not have changed from Step 6

more than about .5 volts.

11. Load the electrical system by turning on the

lights, Hi fan, and wipers.

12. Observe the 16 volt scale on the analyzer. The

voltage should not drop below about 13.0

volts.

13. Shut off all accessories, return the engine to

curb idle, and shut it off . If the results obtained

in Step 6, 10 or 12 are signifi cantly diff erent

from those shown or from the vehicle service

manual values, further diagnosis is required:

see your vehicle service manual.

CRANKING VOLTAGE AND BATTERY CONDITION

If the engine cranks slowly or not at all, the battery,

cranking motor, and associated wiring may be

at fault. Check the cranking voltage as indicated

below.

1. Connect the analyzer to the vehicle battery as

shown in Figure 1.

2. Disable the engine from starting as shown in

Figure 12 or as explained in your vehicle service

manual

3. FUNCTION

SELECTOR

–

Volts

4. Crank the engine while observing the 16 volt

scale on the analyzer.

5. Normal Result – 9.6 volts or more at 70°F. Voltage

will drop slightly as temperature decreases.

6. If the results are signifi cantly out of specifi cation

consult your vehicle service manual for further

ENGINE GROUND

Fig. 12 Disabling Procedure

Breaker Point Ignition System

diagnosis.

7. If battery voltage remains abnormally high

(above approximately 10.5 volts) on a slow

or no cranking engine, the problem may be

loose or corroded connection(s) in the cranking

circuit.

MISCELLANEOUS VOLTAGE TESTS

This instrument can perform many of the voltage

tests called out in the vehicle service manual, such

as voltages at lamp sockets, motors, solenoids

and relays.

NOTE: The voltmeter function of this instrument can

be used anywhere the vehicle service manual calls

for voltage measurement except in those applica-

tions which call for 10 Megohm input impedance

or a digital voltmeter.

IGNITION SYSTEM TEST –

"VOLTS" POSITION

BREAKER POINT RESISTANCE TEST (Breaker Point

Systems Only)

1. Visually check the breaker points and associ-

ated wiring and connections. Check to see that

the lead from the distributor to the Negative

(-) terminal of the ignition coil is not damaged

(nicked insulation, etc.)

2. Remove the distributor cap and inspect the

breaker points. Properly adjusted breaker

points become light gray in color in normal

use. If they are blued, blackened or pitted, they

have exceeded their normal life.

3. To prevent the engine from starting, disable

the ignition system by grounding the coil tower

wire as shown in Figure 12.

4. Connect the GREEN and BLACK clips as de-