8

9

scribed under DWELL/TACH/BREAKER POINT

RESISTANCE MEASUREMENTS

NOTE: When testing a vehicle with dual points,

alternately block one set of points open with a

piece of insulating material while the other set is

being tested.

5. Turn the ignition key ON. If the meter reads

voltage, (12.5 - 13.0) the points are OPEN. Crank

the engine a fraction of a revolution at a time

until the meter reads in the left hand area of

the scale.

The points are now closed.

Test Results:

Normal – Meter reads in the OK zone of the Points

scale. The Analyzer may indicate high point resis-

tance on a new set of points until they have been

run in the vehicle for a few miles and have been

properly seated. This condition may be ignored as

long as any defects discovered during the previous

visual check have been corrected.

Abnormal – If the meter indicates in the Bad zone

when the points are closed, the points may be

defective or the following faults may exist:

Poor distributor ground

Poor connection on the primary lead from

the distributor to the ignition coil

Defective distributor pigtail lead

Misaligned

points

Poor points/plate ground inside distributor

Correct the defect and repeat the test.

IGNITION SYSTEM TEST –

"DWELL" POSITION

DWELL TEST AND ADJUSTMENT – Breaker Point

Systems Only or Transistorized Systems which Use

Breaker Points.

1. Preparation:

Before performing the DWELL TEST AND

ADJUSTMENT PROCEDURE, read the vehicle

emission control label or the vehicle service

manual to determine what should be done with

the vacuum hoses connected to the distributor

and the various advance/retard solenoids. Most

often, the vacuum hose must be disconnected

from the distributor and the end plugged with

a plastic golf “tee” or other plug.

Connect the GREEN and BLACK clips as de-

scribed under TACH/DWELL/BREAKER POINT

RESISTANCE MEASUREMENTS.

2. Test

Procedure:

Start the engine and allow it to warm up (upper

radiator hose hot.)

Operate the engine at curb idle OR the RPM

specifi ed by the vehicle emission control label

or the vehicle service manual for measuring

dwell.

Check the RPM by switching the FUNCTION

SELECTOR TO RPM and reading the appropriate

meter scale. Return the FUNCTION SELECTOR to

DWELL and observe the correct dwell scale

NOTE: There is a direct relationship between dwell

and timing. However, it is only a one way relationship.

If you change the dwell angle of the breaker points,

you will automatically change the ignition timing.

Changing the timing, though, has no eff ect on the

dwell angle. FOR THIS REASON, IT IS IMPORTANT

TO RE-CHECK THE TIMING WHEN EVER THE DWELL

ANGLE HAS BEEN ADJUSTED.

DWELL ADJUSTMENT – Conventional Breaker Point

Systems

On GM distributors with a small metal slide cover,

lift the cover and insert a l/8" Allen wrench in the

adjusting screw socket and adjust the dwell by

turning the wrench, as shown in Figure 13.

On Ford, Chrysler, American Motors, and other

distributors not equipped with a small metal ac-

cess slide cover, perform the following steps while

referring to Figure 14.

1. Remove coil wire from center tower of distributor

cap and ground the wire by connecting the loose

end to the engine or frame, See Figure 12.

2. Remove the distributor cap and rotor.

3. Connect a remote starter switch to the vehicle

or have an assistant crank the engine for you.

4. With ignition switch ON and engine cranking

observe reading on the Dwell scale.

5. To adjust Dwell, loosen the locking screw

slightly and adjust the point gap with a feeler

gauge according to the procedure outlined in

the vehicle service manual. After adjustment,

tighten locking screw, and recheck dwell while

cranking engine. Repeat procedure if necessary.

(Figure 14.)

6. Reassemble distributor and recheck dwell read-

ing with engine operating at idle speed. Repeat

steps 5 and 6 if necessary.

DWELL VARIATION TEST

Read the owner’s manual or engine compartment

decal and follow the instructions regarding vacuum

line or advance-retard solenoid connections when

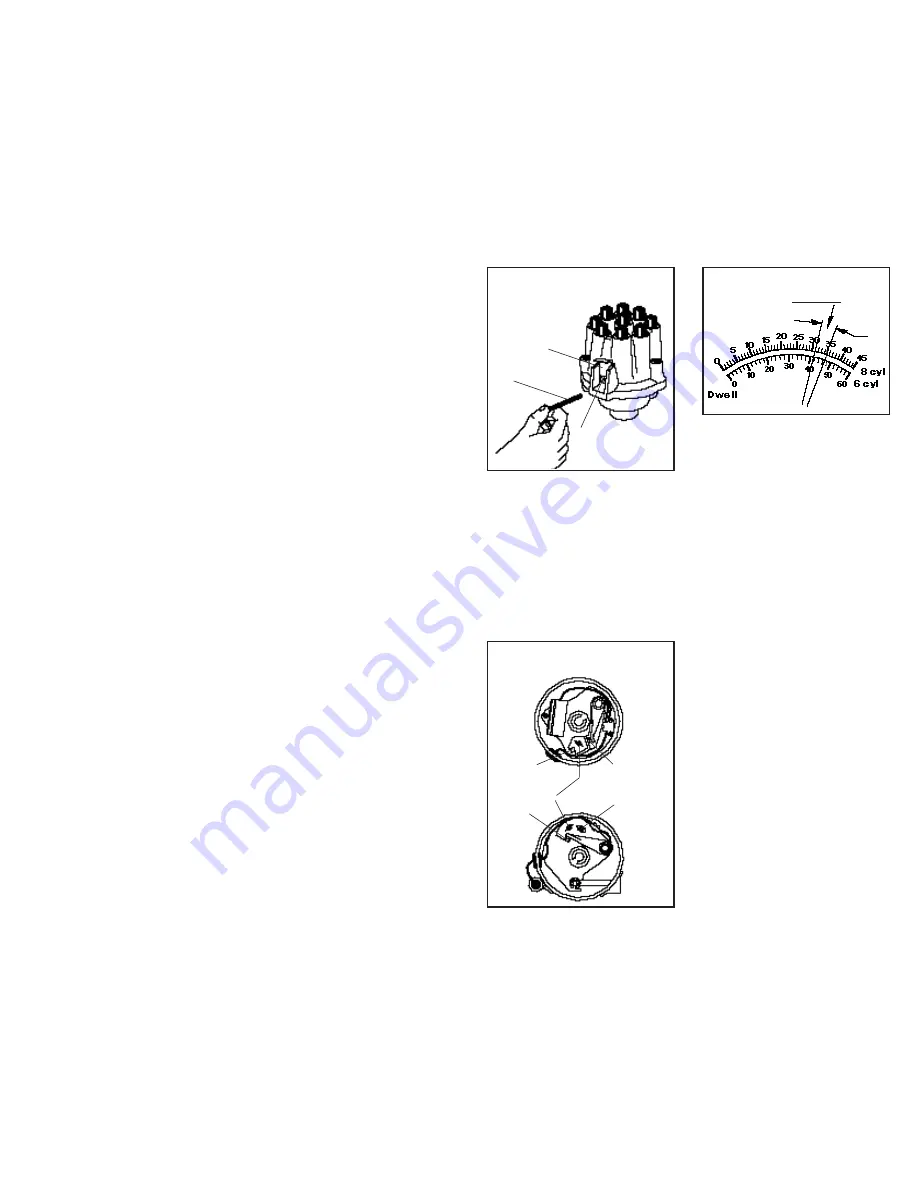

Fig. 13

Typical General Motors

Breaker Points Distributor

WINDOW

ADJUSTMENT

SCREW

1/8" ALLEN

WRENCH

checking DWELL angle. Usually, the vacuum hose

must be disconnected from the distributor and

plugged

Increase the engine speed from idle to about

1500 RPM and note the dwell angle (Figure 15).

Return the engine speed to idle and again note

the dwell angle. If the diff erence between the two

dwell angle readings is more than 3 degrees, check

for excessive wear in the breaker point plate and

couplings or excessive wear in the distributor shaft

gear and bushings.

Fig. 14

Dwell Adjustment

(All, except Delco-Remy Sliding Window Distributors)

ADJUSTMENT

SLOTTED HOLE

BREAKER

POINTS

LOCKING SCREW

ADJUSTMENT

SCREW

BREAKER

POINTS

Fig. 15

Dwell

Variation

SECOND

READING

FIRST

READING

MORE THAN 3 DEGREES

FUEL SYSTEM TESTS –

"DWELL" POSITION

1. General Motors C-3 (Computer Command Con-

trol) Mixture Control Solenoid Dwell (Carbure-

tor equipped vehicles only). The GMC-3 system

controls Air/Fuel ratio with a mixture control

solenoid mounted in the carburetor. The basic

system performance check of this system calls

for the checking of the duty cycle or dwell of

the M/C solenoid. Note that regardless of the

number of cylinders in the vehicle, the reading

is always taken from the 6 cylinder scale.

2. This analyzer may be used to check C-3 Dwell

(duty cycle). Refer to your vehicle service

manual for hookup instructions and perfor-

mance results. See Figure 11.

ENGINE TESTS –

"RPM" POSITION

1. Carburetor Adjustments – There are several

adjustments which should be checked as part

of a performance tune-up. Those which require

engine RPM monitoring are:

a. Curb idle

b. Base idle

c. Solenoid Controlled idle

d. Fast idle

Your vehicle will likely have some combination

of these adjustments. Proper adjustment of

these settings is a requirement for good engine

performance and driveability.

2. Fuel Injection Adjustments – Some fuel injec-

tion systems have a minimum and maximum

authority adjustment which should be checked

during routine performance tune-up or when-

ever idle problems are encountered.

3. Miscellaneous Engine Test – Many of the test