250V MAX

15A MAX

FUSED

COM

DC

15A

OFF

200

20

2

DC V

200

m

20M

200

K

20K

2K

200

8CYL

6CYL

TACH

X10

5CYL

4CYL

8CYL

6CYL

5CYL

4CYL

DWELL

DUTY

CYCLE

%

OHMS

°

15

A

28

Testing Engine Sensors

In the early 1980’s, computer controls were installed in vehicles to meet Federal Government

regulations for lower emissions and better fuel economy. To do its job, a computer-controlled

engine uses electronic sensors to find out what is happening in the engine. The job of the sensor

is to take something the computer needs to know, such as engine temperature, and convert it to

an electrical signal which the computer can understand. The digital multimeter is a useful tool for

checking sensor operation.

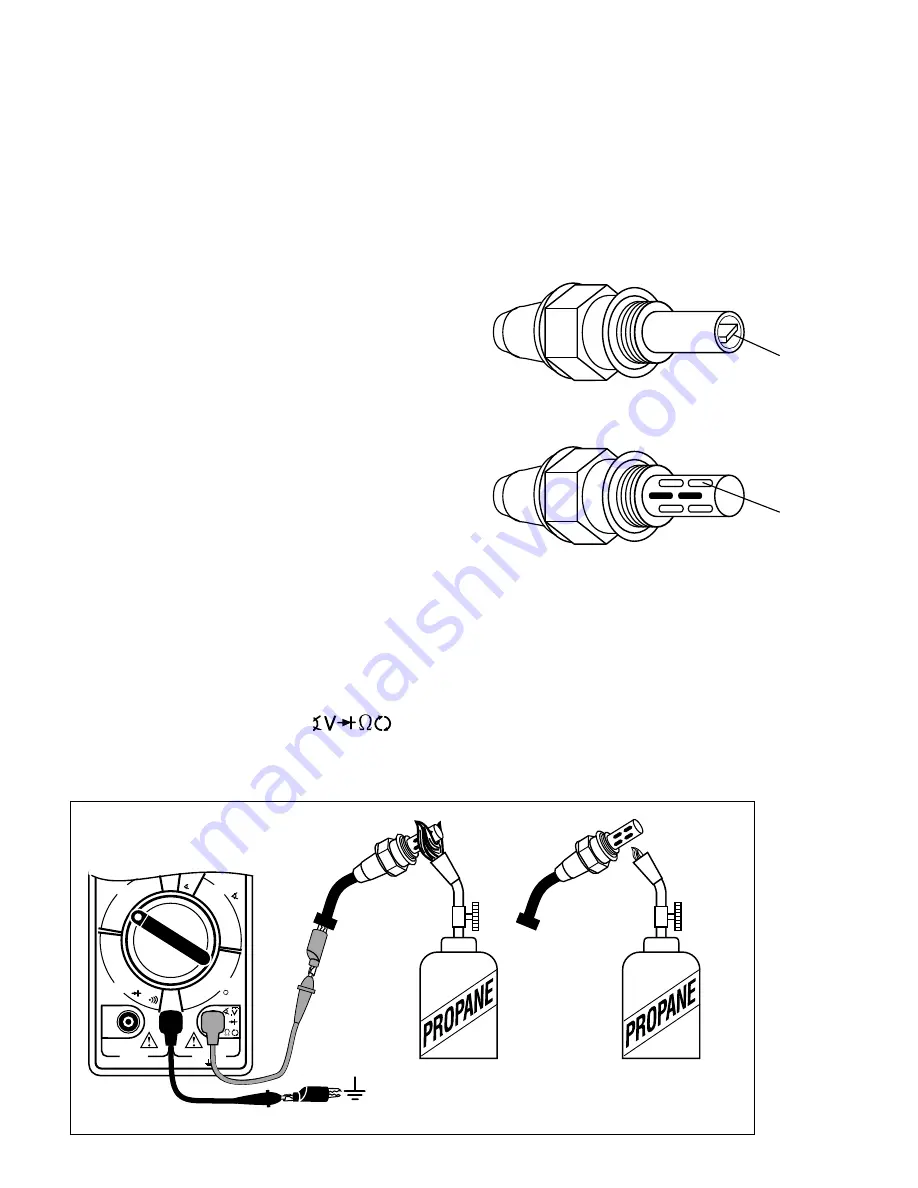

Oxygen (O

2

) Type Sensors

The Oxygen Sensor produces a voltage or

resistance based on the amount of oxygen in

the exhaust stream. A low voltage (high resis-

tance) indicates a lean exhaust (too much

oxygen), while a high voltage (low resistance)

indicates a rich exhaust (not enough oxygen).

The computer uses this voltage to adjust the

air/fuel ratio. The two types of O

2

Sensors

commonly in use are Zirconia and Titania.

Refer to illustration for appearance differ-

ences of the two sensor types.

Test Procedure (see Fig. 30):

1. If engine is HOT, let it COOL down be-

fore proceeding.

2. Remove Oxygen Sensor from vehicle.

3. Insert BLACK test lead into COM test

lead jack.

4. Insert RED test lead into

test

lead jack.

Titania-Type

Oxygen Sensor

Zirconia-Type

Oxygen Sensor

Exposed

flat element

Flutes

Fig. 30

Rich

Lean

Red

5. Test heater circuit.

• If sensor contains 3 or more wires, then

your vehicle uses a heated O

2

sensor.

• Refer to vehicle service manual for loca-

tion of heater pins.

• Connect RED test lead to either heater

pin.

1-wire or 3-wire: Ground is sensor housing

2-wire or 4-wire: Ground is in sensor wiring harness

Ground

Black