Installation and Commissioning Guide - Bulkhead 2 Split System

Doc. No. 9590-5011

Ver. 1 211217

3

Installation and Commissioning Guide

Bulkhead Split System

01. Symbols

Explanation of symbols displayed on the air conditioner. Information About This Guide

This symbol shows that this appliance uses a flammable refrigerant. If the refrigerant leaks and

exposed to an external ignition source, there is a risk of fire.

This symbol shows that the Operation Manual should be read carefully.

This symbol shows that a service person should be handling this equipment with reference to the

Installation Manual.

This symbol shows that there is information included in the Operation Manual and Installation

Manual.

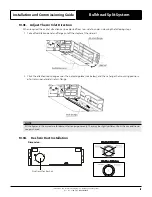

02. Inspection

02.01. Product Inspections

Check your air conditioning unit and all items against the invoice upon receiving your shipment. Inspect the unit,

components and accessories for any sign of damage. If there is any damage to the unit, contact ActronAir Customer Care

Department immediately on:

1300 522 722

to obtain a Goods Return Number.

Check the unit nameplate to verify the model, serial number, electrical rated specifications are correct.

02.02. Codes, Regulations and Standards

The installer and/or contractor assumes responsibility to ensure that unit installation complies with the relevant council,

state / federal codes, regulations and building code standards. All electrical wiring must be in accordance with current

electrical authority regulations and all wiring connections to be as per electrical diagram provided with the unit.

03. General Information

The ActronAir air conditioning units are designed for applications where superior performance, high efficiency, reliability,

supply air quality and quiet operation are the prime priorities.

For optimum efficiency, your air conditioning unit will deliver just the right amount of cooling or heating capacity you

demand. Even in extreme conditions, the unit will still supply the required demand at peak performance.

Energy Efficient Refrigeration Circuits

The ActronAir system is designed with a split ducted refrigeration circuit that delivers only the amount of cooling or

heating actually required to maintain your desired comfort at the most optimum efficiency.

Each refrigeration circuit consists of:

•

High efficiency inverter scroll compressor.

•

Gold hydrophilic coat coil protected condenser designed for optimum performance and efficiency with corrugated

fins and riffled tubing.

•

Gold hydrophilic coat coil protected evaporator coil designed for optimum performance and efficiency with lanced

fins and riffled tubing.

Evaporator Section

The evaporator section has

DC

fans which deliver just the right amount of airflow, depending on requirements. The fans

provide superior performance for your comfort at optimum efficiency:

•

Highly efficient variable speed

DC

motor that uses less energy.

•

Easy variable indoor fan commissioning via intelligent controllers.

•

Low noise operation.