Installation and Commissioning Guide - Classic 2 Split Ducted Outdoor Unit

Doc. No.0525-073 Ver. 8 210414

Installation and Commissioning Guide

Classic 2 Outdoor Units

20

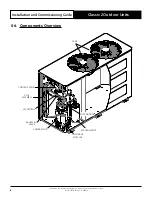

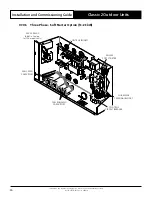

11. Field Pipe Connection

11.01. Piping and Brazing

CAUTION

The units described in this guide use R-410A refrigerant

R-410A operates at a pressure approximately 1.6 times higher than similar systems using R-22. When installing equipment

using R-410A refrigerant, there are number of standards that must be met:

• The system of this unit operates with Polyolester (POE) oil that rapidly absorbs moisture.

• The maximum time any system can be opened to atmosphere is 15 minutes.

• It is important to work with absolute cleanliness.

• Brazing must be done with the use of Nitrogen to avoid carbon deposits into the pipes.

• The system must be evacuated thoroughly to 500 microns (see evacuation procedure).

• The system must always be charged with R-410A refrigerant in liquid state.

• Never allow R-410A refrigerant to vent into the atmosphere. It is an offence to release refrigerant in Australia.

• Always reclaim refrigerant using equipment and container dedicated for R-410A system use only.

• Only qualified technicians are allowed to perform any work described in this guide.

• All work must be carried out in accordance with Australia and New Zealand refrigerant handling code of practice.

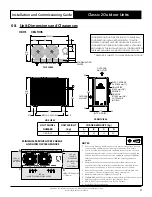

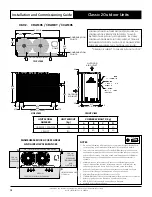

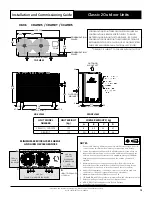

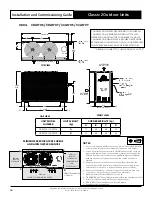

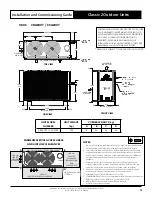

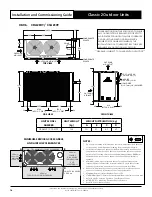

Maximum allowable total equivalent field pipe length is 60 metres, see diagram below. This includes all the equivalent pipe

fitting loses and vertical height difference. Vertical height difference must not exceed 20 metres. Table 1 below shows the

equivalent straight pipe length of elbow fittings.

TABLE 1: EQUIVALENT STRAIGHT PIPE LENGTH OF ELBOW FITTINGS (METRES)

Pipe size Nominal

Diameter

90

o

Long Radius

Elbow

90

o

Short Radius

Elbow

45

o

Long Radius

Elbow

45

o

Short Radius

Elbow

9.52 (3/8”)

0.24

0.36

0.09

0.14

15.88 (5/8”)

0.30

0.45

0.15

0.23

19.05 (3/4”)

0.40

0.60

0.18

0.27

22.22 (7/8”)

0.46

0.69

0.21

0.32

25.4 (1”)

0.52

0.78

0.24

0.36

28.58 (1-1/8”)

0.55

0.83

0.27

0.41

Selected field pipe sizes must match the recommended sizes in table above. If the installation requires different field pipe

diameter due to different application condition other than recommended, contact ActronAir for advice.

Most of unit pipe connections are factory swaged to easily fit to the recommended field pipe diameter.

When it is required to install other refrigeration devices, such as refrigerant drier, solenoid valve and the like, include the

equivalent straight pipe length of the device in the calculation of total equivalent field pipe length.