Installation and Commissioning Guide - Classic 2 Split Ducted Outdoor Unit

Doc. No.0525-073 Ver. 8 210414

Installation and Commissioning Guide

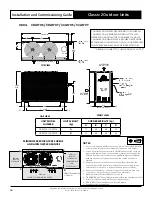

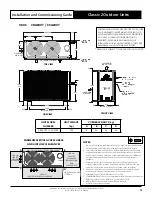

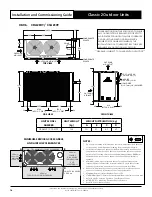

Classic 2 Outdoor Units

24

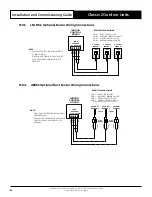

11.02. Pressure Testing

Pressurize the system to 2500kPa in stages. A recommended pressure test is to be performed for no less than 1 hour at

2500kPa.

IMPORTANT

Importance of Evacuation:

• Any non-condensable product left in the system can cause the pressure in the high side of the system to increase and in

turn, the compression temperature to rise.

• Moisture will result in adverse reaction in the refrigerant circuit.

• The POE oil used in the R-410A compressor is hygroscopic, which means that it absorbs moisture from the air. To prevent

chemical reactions in the system, any moisture must be removed at all costs.

• Oxygen (air) reacts with the compressor oil and can lead to faults such as compressor failure.

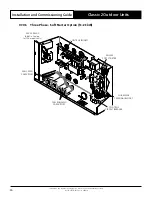

BRAZE

JOINTS

To

Indoor Unit

See Diagram Below:

N

I

T

R

O

G

E

N

NITROGEN

HOSE

11.03. Evacuation Procedure (Triple Evacuation)

1. Fit service gauges to the ball valves (liquid line service valve and suction line service valve).

2. Evacuate the system to 1000 microns.

3. Check vacuum with vacu stat. Break the vacuum with dry Nitrogen to 100kPa

4. Release Nitrogen pressure. Evacuate to 500 microns.

5. Check vacuum with vacu stat. Break the vacuum with dry Nitrogen to 100kPa

6. Release Nitrogen pressure. Evacuate to 500 microns.

7. Check vacuum with vacu stat. Let the unit stand for 1 hour and with the vacuum not rising above 500 microns.

8. Open valve.

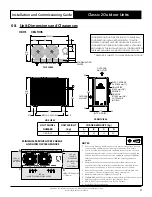

TO OPEN TURN ANTI-CLOCK WISE (1/4 TURN)

TO CLOSE TURN CLOCK WISE (1/4 TURN)

(As Shipped Position)

(Operating Position)

CLOSE

OPEN

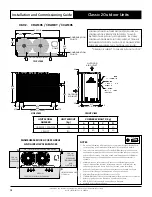

TO OPEN TURN ANTI-CLOCK WISE (1/4 TURN)

( As Shipped Position )

CLOSE

TO CLOSE TURN CLOCK WISE (1/4 TURN)

( Operating Position )

OPEN

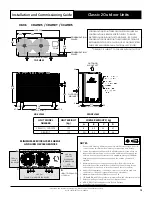

OPEN

CLOSED

Wrench Key

( OPEN = Operating Position )

( CLOSED = As Shipped Position )