Installation and Commissioning Guide - Classic 2 Split Ducted Outdoor Unit

Doc. No.0525-073 Ver. 8 210414

Installation and Commissioning Guide

Classic 2 Outdoor Units

46

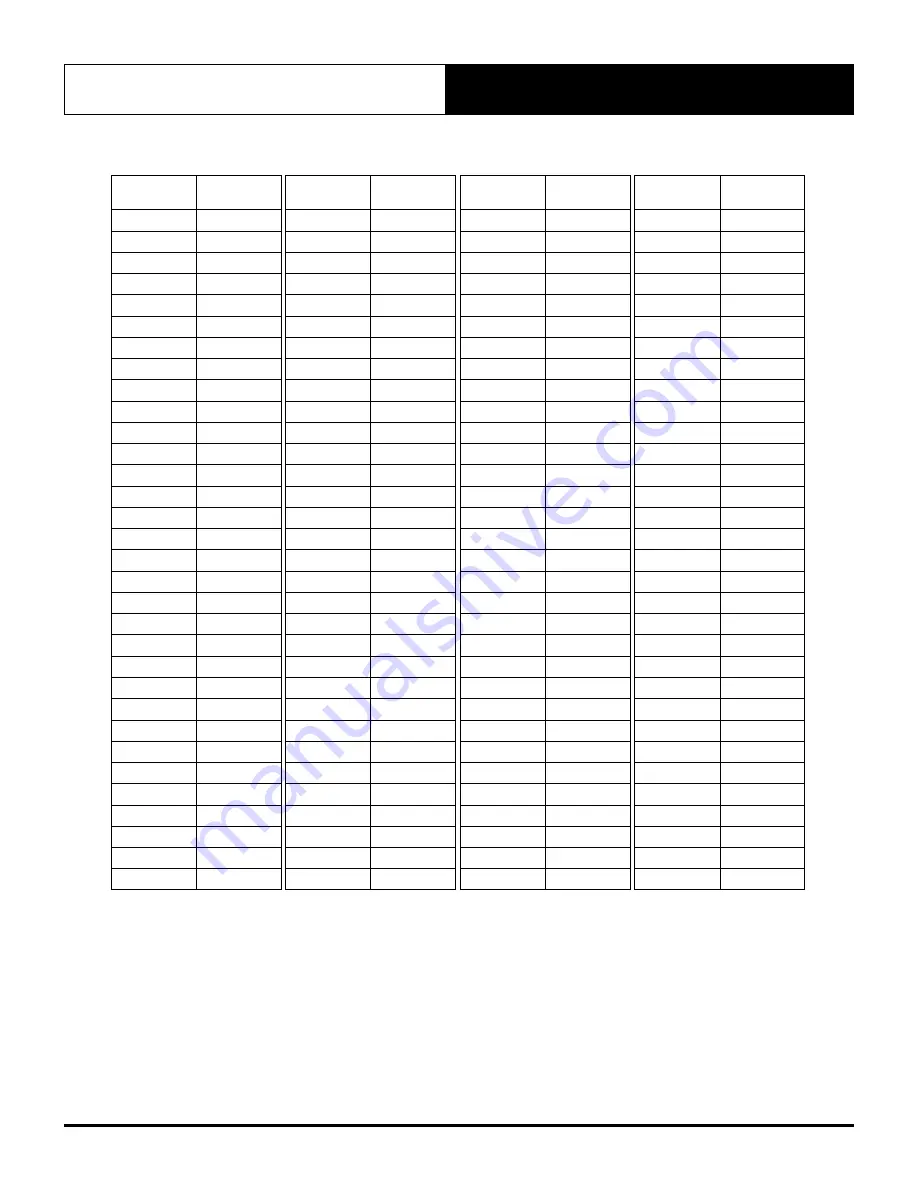

CHARGING TABLE

Temp

o

C

Pressure

KPa

Temp

o

C

Pressure

KPa

Temp

o

C

Pressure

KPa

Temp

o

C

Pressure

KPa

- 60

- 34.4

- 28

194.9

4

805.9

36

2090.7

- 59

- 30.7

- 27

206.9

5

834.1

37

2145.5

- 58

- 26.8

- 26

219.2

6

862.9

38

2201.3

- 57

- 22.8

- 25

231.9

7

892.6

39

2258.2

- 56

- 18.6

- 24

245.1

8

922.8

40

2316.1

- 55

- 14.2

- 23

258.7

9

953.8

41

2375.1

- 54

- 9.6

- 22

272.6

10

985.4

42

2435.1

- 53

- 4.8

- 21

286.9

11

1017.8

43

2496.2

- 52

0.8

- 20

301.7

12

1050.9

44

2558.5

- 51

5.3

- 19

316.9

13

1084.7

45

2621.8

- 50

10.7

- 18

332.6

14

1119.2

46

2686.2

- 49

16.3

- 17

348.7

15

1154.6

47

2751.8

- 48

22.2

- 16

365.2

16

1190.7

48

2818.5

- 47

28.2

- 15

382.3

17

1227.5

49

2886.4

- 46

34.0

- 14

399.7

18

1265.2

50

2955.5

- 45

40.9

- 13

417.7

19

1303.6

51

3025.7

- 44

47.8

- 12

436.2

20

1342.9

52

3097.2

- 43

54.8

- 11

455.1

21

1382.9

53

3169.9

- 42

62.1

- 10

474.6

22

1423.9

54

3243.7

- 41

69.6

- 9

494.6

23

1465.7

55

3318.9

- 40

77.4

- 8

515.1

24

1508.3

56

3395.2

- 39

85.5

- 7

536.2

25

1551.8

57

3472.9

- 38

93.9

- 6

557.8

26

1596.2

58

3551.8

- 37

102.5

- 5

579.9

27

1641.4

59

3631.9

- 36

111.5

- 4

602.6

28

1687.6

60

3713.5

- 35

120.8

- 3

625.9

29

1734.6

61

3796.3

- 34

130.4

- 2

649.8

30

1782.6

62

3880.5

- 33

140.3

- 1

674.3

31

1831.6

63

3965.9

- 32

150.5

0

699.4

32

1881.5

64

4052.8

- 31

161.1

1

724.9

33

1932.3

65

4140.9

- 30

171.9

2

751.3

34

1984.1

66

4230.6

- 29

183.3

3

778.3

35

2036.9

67

4321.5