PRELIMINARY DATA ONLY Ver. 5.01 210406

THIS LABEL TO BE REMOVED ON SIGN-OFF

16

Installation and Commissioning Guide- Package Ducted Variable Capacity Commercial

Doc. Part No. 0525-067 Ver. 5 210414

Installation and Commissioning Guide

Variable Capacity Commercial

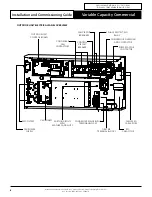

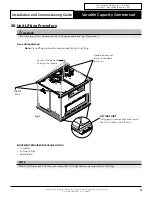

Procedure:

1. Remove all screws and washers that secure the unit to the timber pallet.

2. Use 4 x Bow or Dee shackle to connect the lifting holes.

3. Slip nylon slings through all shackles.

4. Ensure slings are protected by rubber pads or similar if slings are draped across the unit edges and corners. This will pre-

vent the unit from being damaged during lifting.

5. SPREADER BAR must be used when lifting the unit.

DANGER

Make sure rigging equipment, accessories and plant are sufficiently and safely capable to lift the unit in order to prevent

potential damage to property, severe personal injury or death. Check unit weight and weight distribution points on unit

drawing dimensions section.

NOTES

• Lifting procedure and unit model shown are suggestions and for illustration purposes only.

• It is highly recommended that installer observe current industry safe and sound rigging and lifting procedure.

CAUTION

Length of fork lift tines must pass the unit middle section, in order to safely carry the unit.

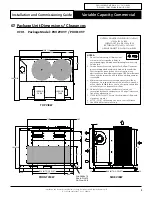

Fork Lift Method

Procedure:

1. To move the unit around with a forklift, insert the fork tines through the unit feet assembly, as shown in Fig. 2.

2. Only fork the unit through compressor end or side of the unit.

(See illustration for location of compressor end)

CAUTION

DO NOT LIFT from this end

Fig. 2

COMPRESSOR

END

Insert forklift tines

here