Installation and Commissioning Guide - Standard Commercial Split Ducted Commercial Outdoor Unit

Doc. No.0525-056

Ver. 7 220308

Installation and Commissioning Guide

Split Ducted Outdoor Units

16

THIRD ANGLE

PROJECTION

0525-

0XX I

nst

all G

uid

e C

om

mer

cial

Spl

it V

1 - P

age 2

1 - 4

D

E

F

C

B

A

3

2

1

5

C

D

4

6

7

8

A

B

0525-0XX Install Guide Commercial Split V1 - Page 21 - 4

A3

SHEET 1 OF 1

N.T.S

DRAWING NO.

MATERIAL:

DESCRIPTION:

DATE

DRAWN BY:

APPROVED BY:

SCALE:

DRAWN DATE:

DESCRIPTION

FINISH:

REV

PCR

F

E

REV.

BY

7.

3

1.

HOLE DIAMETER

A.B.N. 34 002 767 240

PH. +61 2 8814 4000

Bella Vista NSW 2153

Norwest Business Park

5 Irvine Place

written consent is prohibited

Modifying or Distributing without

Engineering Pty Ltd. Copying,

4.

intellectual property of Actron

This drawing always remains the

ActronAir Pty Ltd

ANGLES & SQUARENESS

0.1/~0

2.

FLAT PATTERN

1

0.5 / m

3.

FOLD

5.

0.5 / m

GENERAL TOLERANCES

(UNLESS OTHERWISE SPECIFIED)

ALL TUBES

UNLESS OTHERWISE SPECIFIED

3rd ANGLE PROJECTION.

1.

DIMENSIONS IN MILLIMETRES.

2.

DO NOT SCALE.

3.

TUBE ENDS MUST BE ROUND AND OF FULL

4.

DIAMETER.

TUBE MUST BE CLEAN AND FREE FROM

5.

BURRS INSIDE AND OUTSIDE AND SUITABLE

OF FOR SOLDERING.

ALL BENDS 90 .

6.

ALL SHEETMETAL'S DIMENSIONS OUTISDE.

ASS

EMBLY

Step 3: Install Interconnecting Field Pipes

Braze refrigeration piping. Refer to Section 11 for details of field pipe sizes and piping installation procedure.

WARNING

Live electrical within enclosure. Isolate electrical supply before

removing panels. Authorised technicians access only.

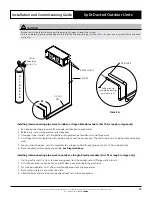

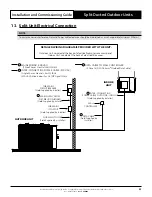

11. Field Pipe Connection

11.01. Piping and Brazing

CAUTION

The units described in this guide use R-410A refrigerant

R-410A operates at a pressure approximately 1.6 times higher than similar systems using R-22. When installing equipment

using R-410A refrigerant, there are number of standards that must be met:

• The compressor of this unit operates with Polyolester (POE) oil that rapidly absorbs moisture. The maximum time any

system can opened to atmosphere is 15 minutes, if the system is left open for extended period cap it off to prevent the oil

from absorbing moisture.

• It is important to work with absolute cleanliness.

• Brazing must be done with the use of Nitrogen to avoid carbon deposits into the pipes.

• The system must be evacuated thoroughly to 500 microns (see evacuation procedure).

• The system must always be charged with R-410A refrigerant in liquid state.

• Never allow R-410A refrigerant to vent into the atmosphere. It is an offence to release refrigerant in Australia.

• Always reclaim refrigerant using equipment and container dedicated for R-410A system use only.

• Only qualified technicians are allowed to perform any work described in this guide.

• All work must be carried out in accordance with Australia and New Zealand refrigerant handling code of practice.

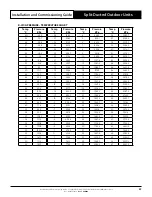

Maximum allowable total equivalent field pipe length is 60 metres, see diagram below. This includes all the equivalent pipe

fitting loses and vertical height difference. Vertical height difference must not exceed 20 metres. Table 1 below shows the

equivalent straight pipe length of elbow fittings.