Installation and Commissioning Guide

Split Ducted Outdoor Units

Installation and Commissioning Guide - Standard Commercial Split Ducted Commercial Outdoor Unit

Doc. No.0525-056

Ver. 7 220308

27

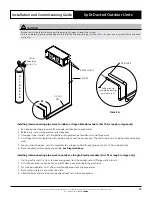

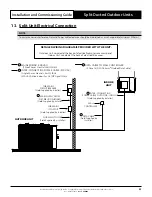

2. Connect service gauges to the shut off valves.

3. Start the unit in cool mode ensuring that the compressor is in 100% operation before taking service gauges

reading. Allow the system to stabilise for next 15 - 30 minutes before recording.

4. Record the discharge pressure, suction pressure, liquid line temperature and suction line temperature for

all the refrigeration circuits.

Discharge Pressure = ________________ kPa

Suction Pressure = __________________ kPa

Liquid Line Temperature

(LLT)

= _______

O

C

Suction Line Temperature

(SLT)

= ______

O

C

NOTES

• Accurate pressure and temperature measuring tools should be used to achieve satisfactory results.

• The sensors of thermocouple must be in good contact with the area being measured and must be insulated in

order to obtain correct reading.

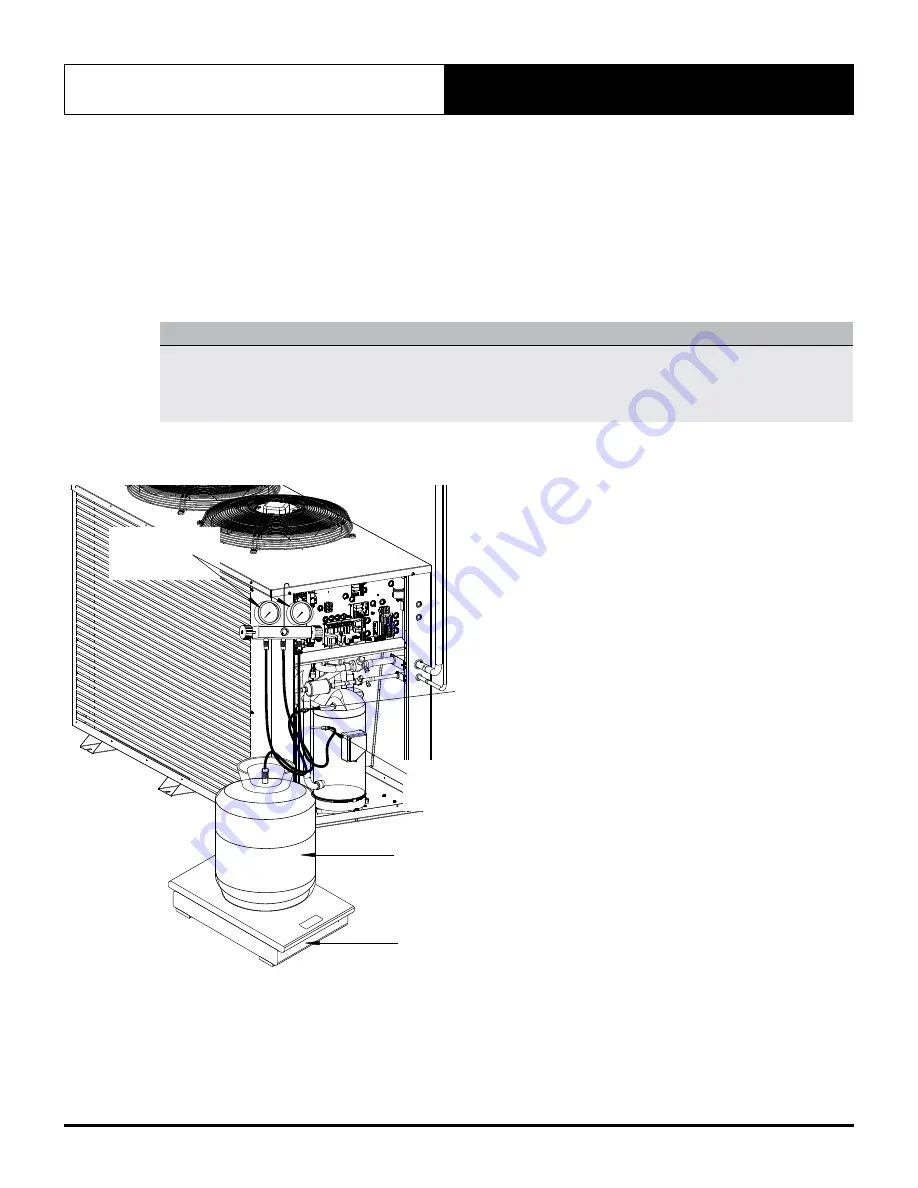

• For illustration purpose only. Valve location may vary depending on unit model.

* Use weighing scale when adding

or removing refrigerant charge.

See Diagram Below:

See Diagram Below:

SERVICE

GAUGES

R-410A *

REFRIGERANT

CONTAINER

WEIGHING SCALE

DISCHARGE

SCHRADER VALVE

SUCTION

SCHRADER VALVE

Unit shown represents 1-Stage model.

Checking for Subcooling

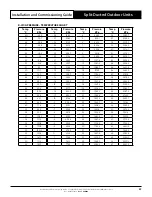

1. From the R-410A Pressure / Temperature Chart record the corresponding Saturated Condensing

Temperature (

SCT

) at the given discharge pressure.

2. Calculate the system subcooling using the formula below:

Subcooling = SCT - LLT