Page 20

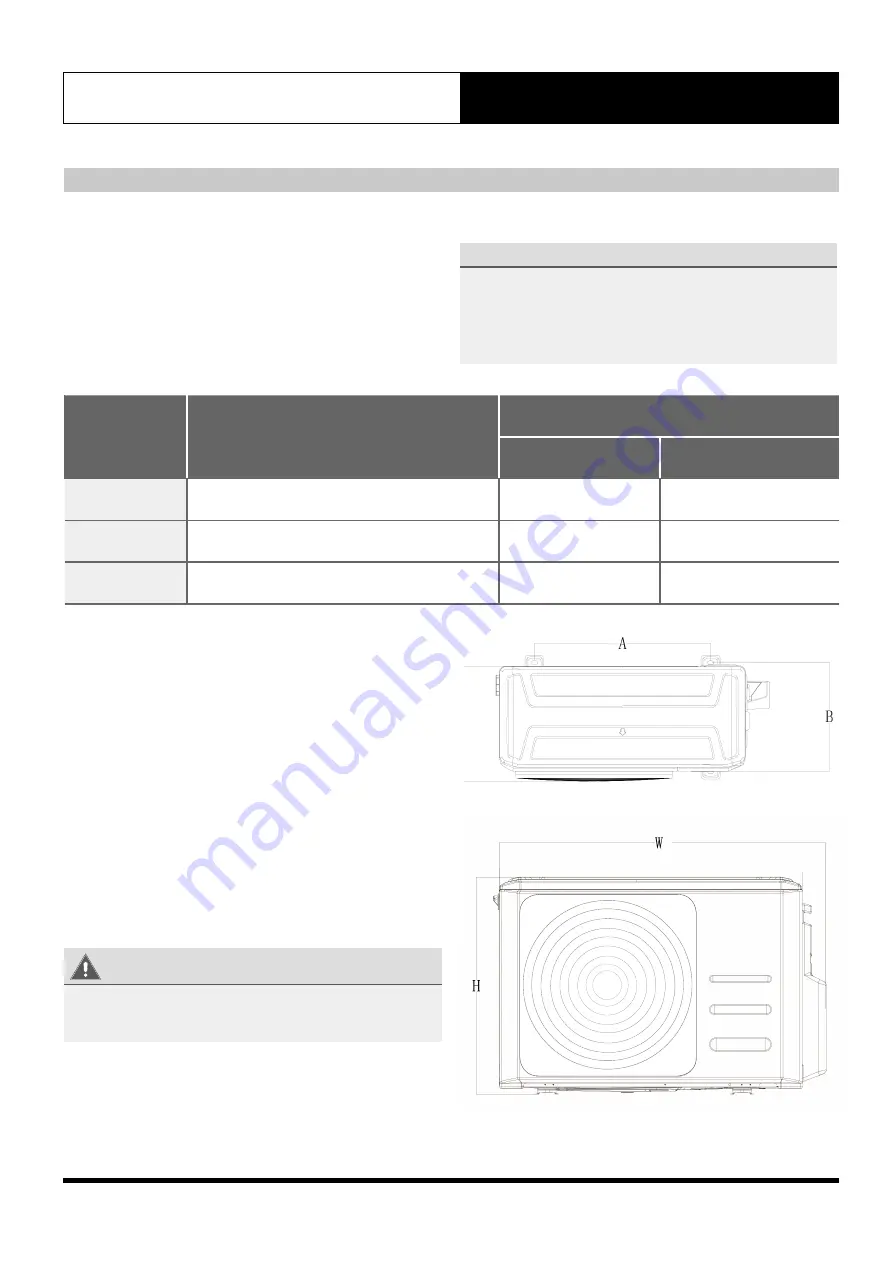

Model Number

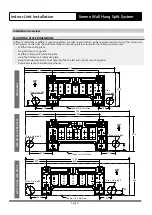

Outdoor Unit Dimensions (mm)

W x H x D

Mounting Dimensions

Distance A

(mm)

Distance B

(mm)

WRC-026AS

WRC-035AS

800 x 554 x 333

514

340

WRC-050AS

845 x 702 x 363

540

350

WRC-071AS

WRC-080AS

946 x 810 x 410

673

403

If you will install the unit on the ground or on a concrete

mounting platform, do the following:

1. Mark the positions for four expansion bolts based on

dimensions in the Unit Mounting Dimensions chart.

2. Pre-drill holes for expansion bolts.

3. Clean concrete dust away from holes.

4. Place a nut on the end of each expansion bolt.

5. Hammer expansion bolts into the pre-drilled holes.

6. Remove the nuts from expansion bolts, and place

outdoor unit on bolts.

7. Put washer on each expansion bolt, then replace the

nuts.

8. Using a wrench, tighten each nut until snug.

WARNING

WHEN DRILLING INTO CONCRETE, EYE

PROTECTION IS RECOMMENDED AT ALL TIMES.

6. Outdoor Unit Installation

Serene Wall Hung Split System

Step 3: Anchor outdoor unit

The outdoor unit can be anchored to the ground or to a

wall-mounted bracket.

UNIT MOUNTING DIMENSIONS

The following is a list of different outdoor unit sizes and

the distance between their mounting feet. Prepare the

installation base of the unit according to the dimensions

below.

Installation Overview

Fig. 6.5