Page 8

Title

Low Profile Split Ducted Air Conditioner

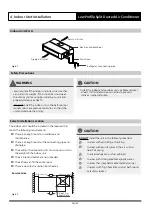

4. Indoor Unit Installation

Low Profile Split Ducted Air Conditioner

Model

Outline Dimension

Air Outlet

Opening Size

Return Air

Opening Size

Mounting Distance

Centre to Centre

A

B

C

D

E

F

G

H

I

J

LRE-071AS

1100

249

774

700

175

926

228

1001

1140

598

LRE-100AS

1360

249

774

700

175

1186

228

1261

1400

598

LRE-130AS

1200

300

874

800

227

1044

280

1101

1240

697

LRE-170AS

1400

440

858

770

385

1188

385

1188

1436

700

Table 4.1

(unit mm)

Dimension and Supply Air Outlet Size

Return Air Inlet Size:

Please refer to the following data to locate the four positioning screw bolt hole on the ceiling. Be sure to mark the areas

where ceiling hook holes will be drilled.

Indoor Unit Dimensions

Horizontal

End

H

G

C

D

A

F

B

E

Position of the down supply opening and size of hanging hook

Return Air Inlet Bottom Entry

Electric control box

Hole Diameter =

14mm x 40mm

J

I

Fig.4.3